Mine ventilation mash gas burning and heat energy using device

A technology for mine ventilation and gas, which is applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problems of difficult combustion and stable porous media, complex equipment structure and operation, and difficult positioning of porous media, etc., to improve combustion stability. performance and completeness, avoid end face heat loss, and reduce the effect of concentration limit

Inactive Publication Date: 2010-12-01

UNIV OF SCI & TECH OF CHINA

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the problem existing in both is that regular airflow reversal is required; and in order to avoid a large amount of heat dissipation and maintain stable combustion, a good heat insulation layer is required around the reactor, resulting in complicated equipment structure and operation

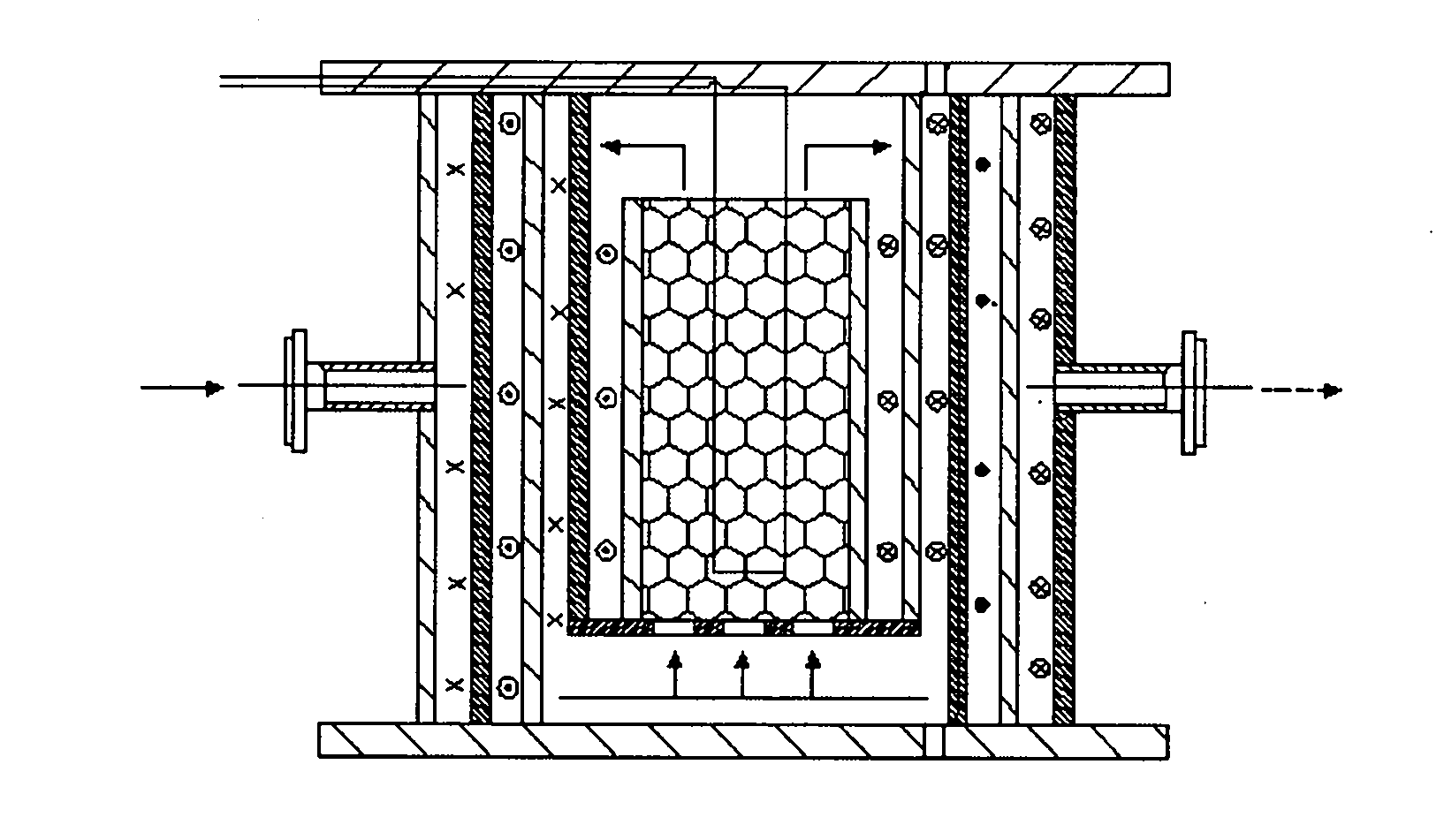

The author's research group designed a new type of annular burner (Chinese patent: CN201021800, 2008.02.13), which can solve the problems of the above two devices CFRR and TFRR. However, the author found in further research that the annular combustion The combustion center area of the device - the porous medium is difficult to locate; the partition needs to be made of high temperature resistant materials, the structure is complex, and the manufacturing cost increases; due to the existence of the partition, there are special requirements for the shape of the porous medium, which increases the difficulty of processing; In addition, the combustion path of mine ventilation gas in this structure is short, and the combustion is not easy to stabilize inside the porous medium, resulting in runaway temperature (the high temperature area drifts from the porous medium to the annular channel, and then drifts out of the burner from the annular channel) or flameout phenomenon

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

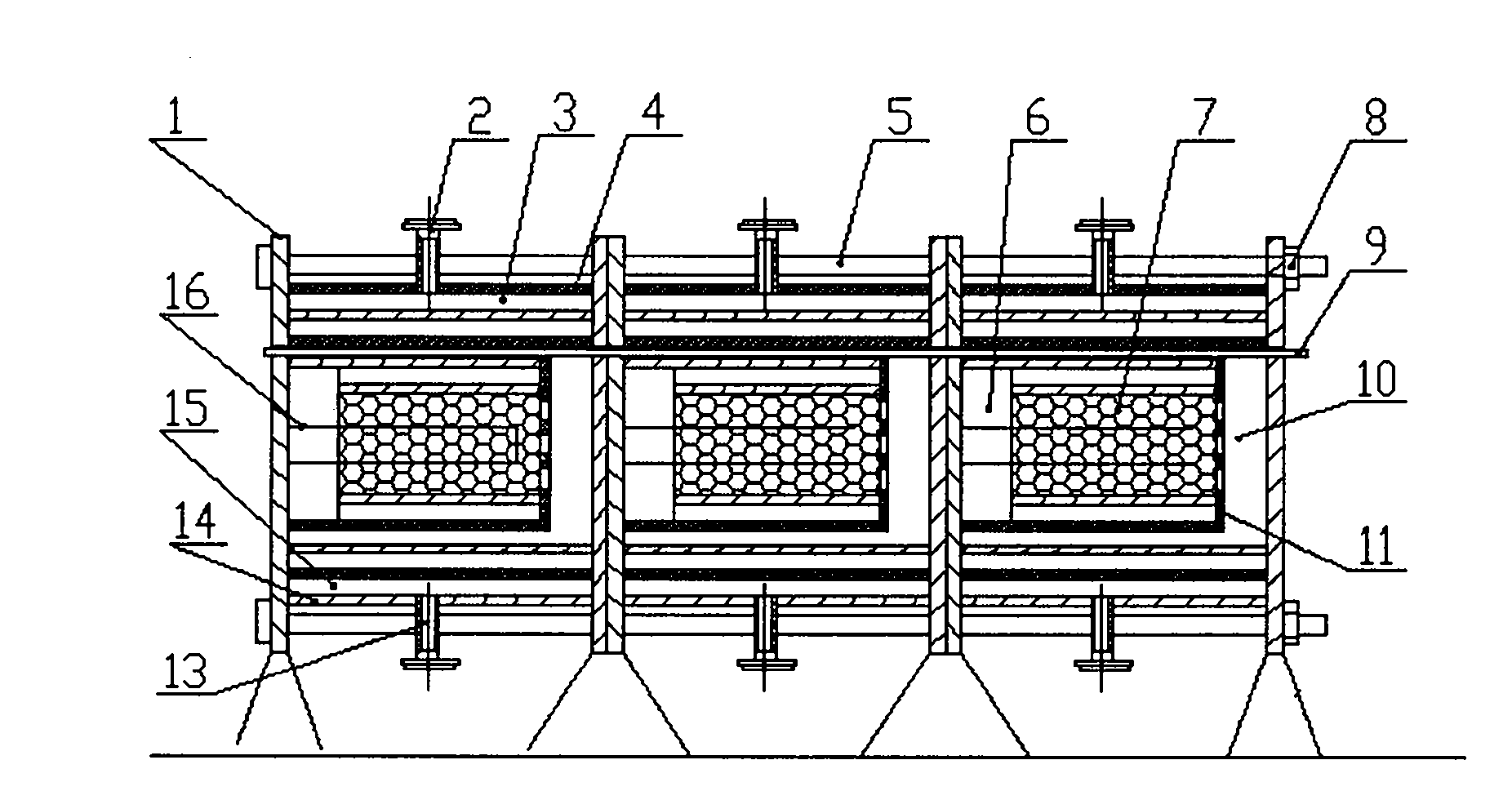

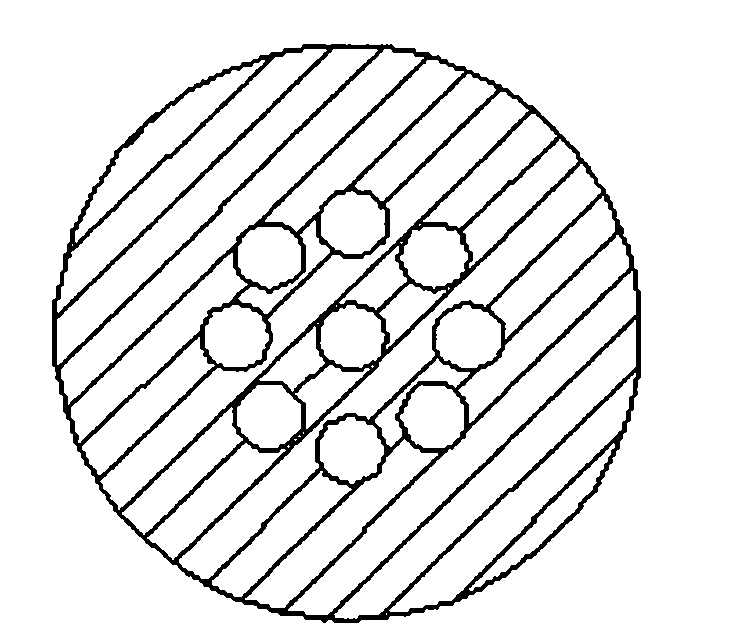

Login to View More Abstract

This invention belongs to the thermal energy utilization device of the mine ventilation gas and includes the counter current circular channel, the centrally positioned porous material and high temperature resistant heat pipe. The mine ventilation gas is conducted circlewise to the bottom of the combustion center, rectified by the gas distribution board, and combusted axially inside the porous medium. The flume is marshaled above and conducted to the circular channel for heat exchange with the mine ventilation gas. Through parallel installation of the combustion units, the real time control ofthe operational number of combustor based on the mine ventilation gas flux, the control of steam flux and electrical heating components in the high temperature heat pipe based on the temperature of the combusting area, this invention meets the requirement of mine ventilation gas processing on the flux and concentration, and ensures the stable operation of the devices.

Description

A Mine Ventilation Gas Combustion and Heat Energy Utilization Device Technical field: The invention belongs to the technical field of combustion equipment, in particular to a combustion and heat energy utilization device for mine ventilation gas. Background technique: Coalbed methane is a kind of unconventional natural gas that is self-generated and self-storage in the process of coal-forming coal-forming substances mainly composed of humic organic substances in coal-bearing rock formations. It is commonly known as gas, and its main component is methane, accounting for more than 90%. Coalbed methane has always been regarded as a harmful gas that poses a serious safety threat to coal mining. In the history of coal mining, many gas, coal dust explosion accidents and coal and gas outburst accidents have been caused by mine ventilation gas. Moreover, methane, as the main component of mine ventilation gas, has a calorific value of 3.43-3.71MJ / Nm3 at room temperature, and its ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23C5/08F23G7/06

Inventor 马培勇林其钊俞瑜扈鹏飞

Owner UNIV OF SCI & TECH OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com