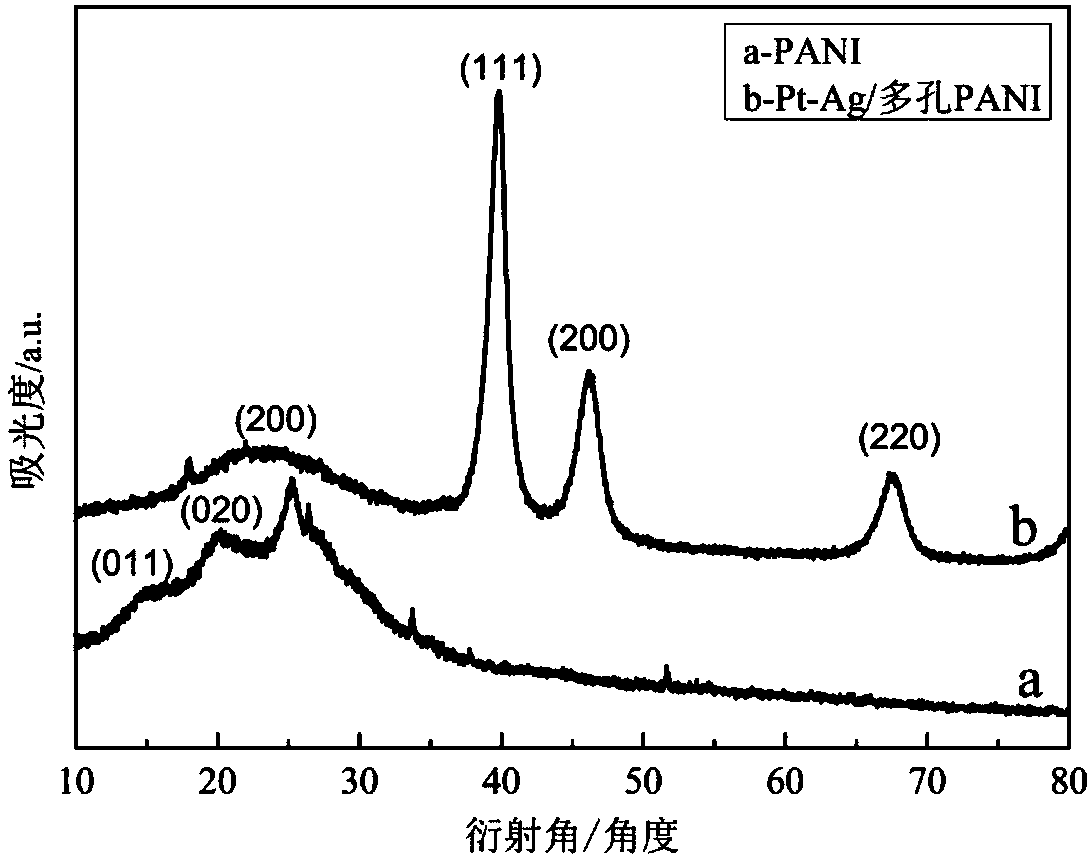

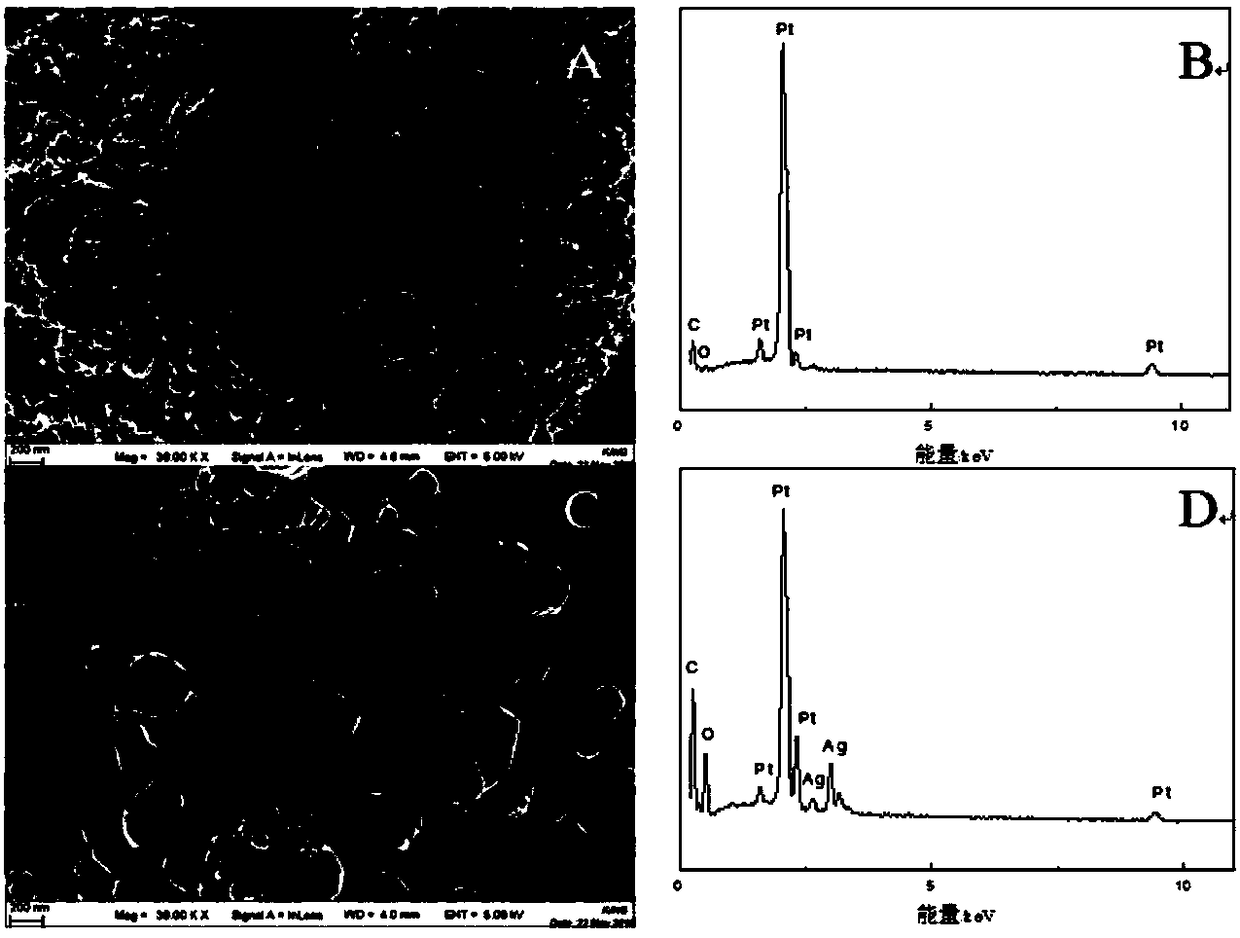

Preparation method of Pt-Ag/porous polyaniline electrode material

A technology of electrodes and composite materials, which is applied in the field of preparation of Pt-Ag/porous polyaniline electrode materials, can solve the problems of high price, limited resources of Pt catalytic materials, hindering commercial application, etc., and achieve good stability and high catalytic activity , the effect of high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve 1.0 g of aniline (An) and 0.5 g of sodium dodecylbenzenesulfonate (SDBS) in 31 mL of 0.5 M sulfuric acid solution (labeled solution A), where sulfuric acid is used as a protonic acid dopant. Add a certain amount of ATP to solution A to obtain a mixed solution, then add 2.84g of ammonium persulfate to dissolve in 31mL of 0.5M sulfuric acid (labeled solution B), slowly add the resulting solution B to the mixed solution, and stir Next, add aniline dropwise (one drop every 3 seconds) using a dropping funnel. Thereafter, the mixed liquid was kept at 0° C., stirred continuously for 8 hours and then left to stand overnight. The resulting mixture was filtered and washed with distilled water and ethanol until the filtrate was colorless, then dried at 60° C. for 24 hours, and ground to obtain PANI / ATP homogeneous powder. Finally, 0.8 g PANI / ATP was added into the HF acid solution and stirred continuously for 11 h to remove the ATP template, and finally filtered, was...

Embodiment 2

[0024] Disperse the carrier prepared in step 1 in deionized water and stir for about 30 minutes. The effect of deposition sequence on the catalytic effect of glycerol was investigated by stepwise deposition, and the cyclic voltammetry curve of the product was detected. In 0.5M glycerol + 0.5M H 2 SO 4 In solution, the scan rate is 0.1V s -1 , the scan parameters are set at -0.2V–1.0V, and a CV test is performed.

Embodiment 3

[0026] Disperse the carrier prepared in step 1 in deionized water and stir for about 30 minutes. The CV method is used to deposit Pt and Ag on the surface of the electrode. The number of circles set during the deposition is different, and the catalytic effect obtained is also different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com