Crystallizer model for flow field research in crystallizer and crystallizer flow field simulation method

A simulation method and crystallizer technology, applied in teaching models, instruments, educational tools, etc., can solve problems such as poor results, and achieve the effect of ensuring optimal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

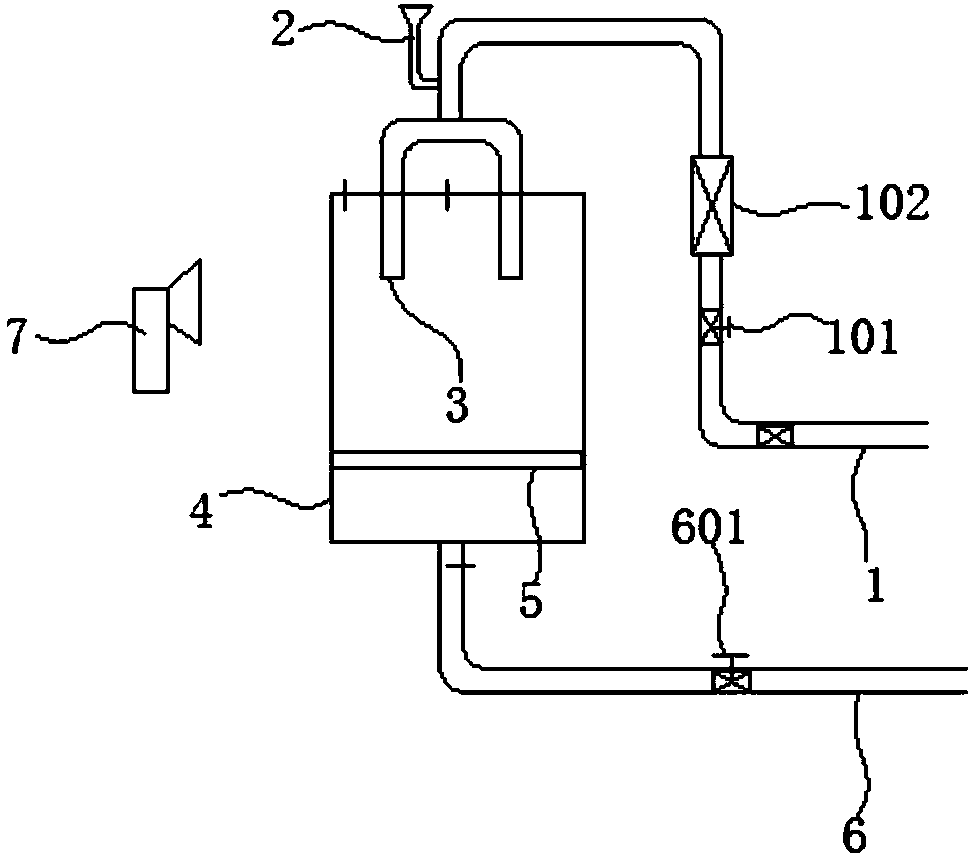

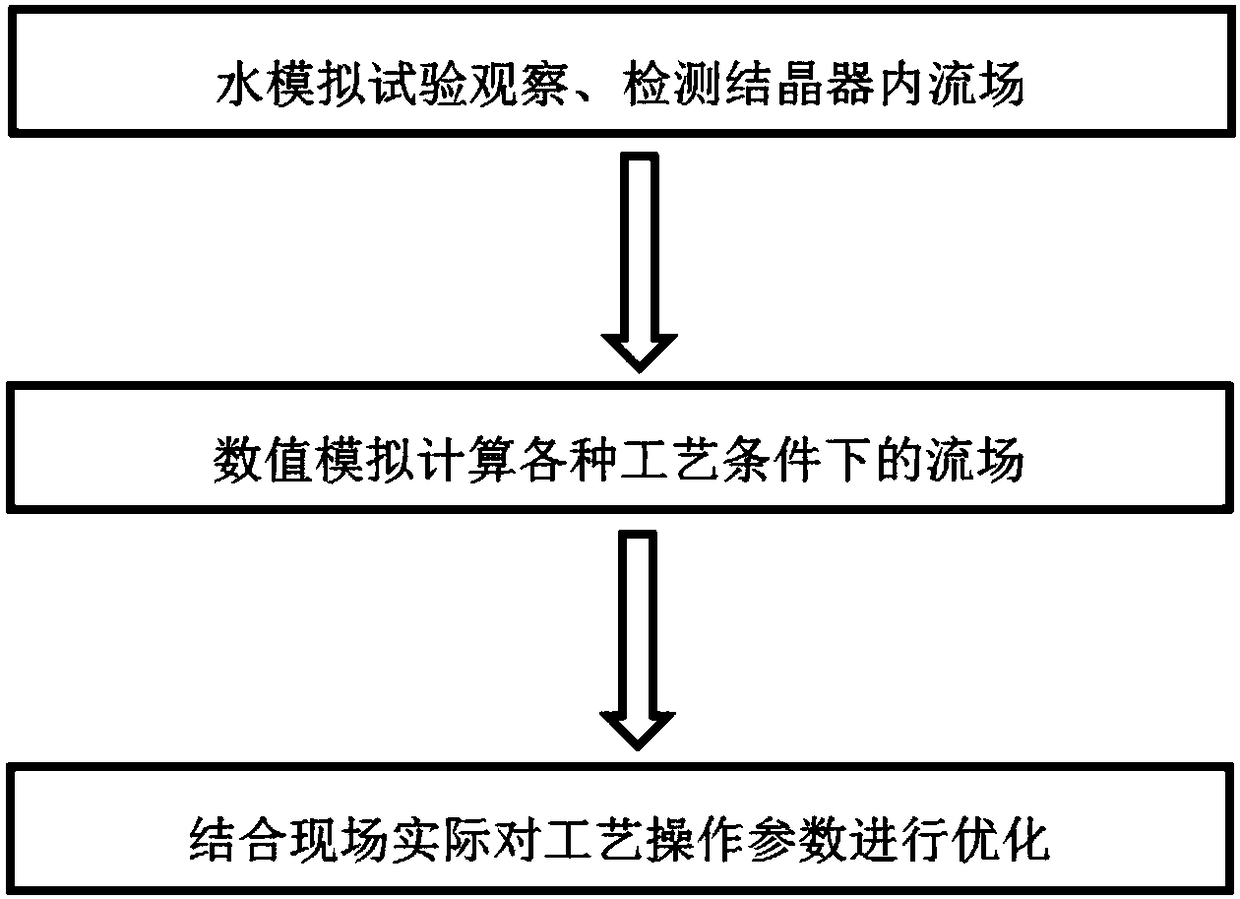

[0037] Such as figure 1As shown, a crystallizer model used in the study of the flow field in the crystallizer in this embodiment includes a crystallizer body 4, and the top of the crystallizer body 4 is provided with a submerged nozzle 3, which is connected to the water inlet pipe 1 Connected, the bottom of the crystallizer body 4 is provided with a water outlet, and the inside of the crystallizer body 4 is provided with a flow distributor 5 . Physical simulation is currently the main means of research on the flow field in the mold, and the establishment of the mold model is very important for the simulation results and the optimization effect of the mold flow field. During the research process, the applicant found that when using the existing crystallizer model for simulation, the vortex phenomenon is likely to occur at the outlet of the model, and the flow field generated by the eddy current will superimpose with the flow field of the crystallizer itself, which is not consid...

Embodiment 2

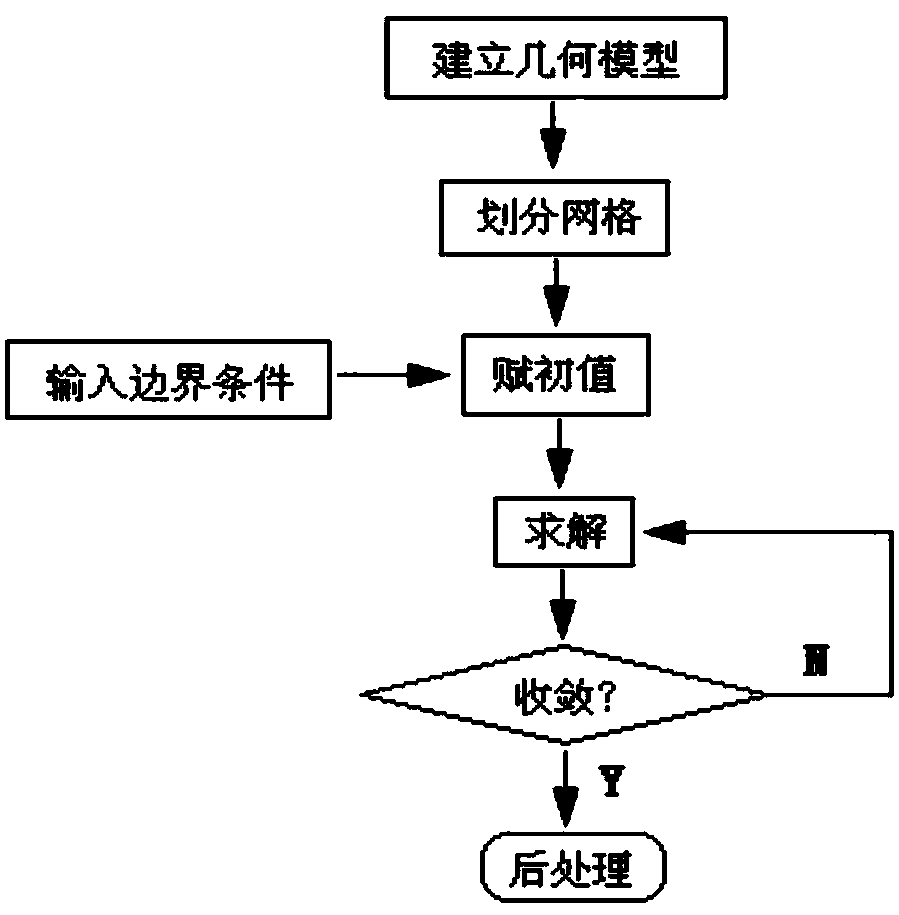

[0040] A kind of crystallizer model that is used for the study of the flow field in the crystallizer of this embodiment, its structure is basically the same as embodiment 1, and its difference mainly lies in: the shape and size of the flow distributor 5 and the inner cavity of the crystallizer body 4 match. The flow distributor 5 of this embodiment is installed at 180-200mm from the bottom of the crystallizer body 4, and its thickness is 18-22mm. The flow distributor 5 is processed with evenly distributed openings, and all the openings on the flow distributor 5 The total area S of is:

[0041]

[0042] where V m is the model velocity, A m is the cross-sectional area of the model, V s is billet casting speed, A s is the billet cross-sectional area, Q s is the field flow, according to the formula Q s = The weight of molten steel in the ladle / the pouring period of the ladle is calculated. Through a large number of experiments, the applicant optimized the installation ...

Embodiment 3

[0044] A kind of crystallizer model that is used for the study of flow field in the crystallizer of this embodiment, its structure is basically the same as embodiment 2, and its difference mainly lies in: the first valve 101 and flowmeter 102 are arranged on the described inlet pipe 1, and A funnel 2 is provided on the water inlet pipe 1 close to the submerged nozzle 3 , and the funnel 2 is used for adding tracer into the crystallizer body 4 . The water outlet at the bottom of the crystallizer body 4 is connected to the water outlet pipe 6, the water outlet pipe 6 is provided with a second valve 601, and the crystallizer body 4 is provided with a conductivity meter, a DJ800 detection system and a wave height meter, and the crystallizer body 4. A video camera and a polarized light source 7 are arranged on the outside.

[0045] The water simulation experiment of the crystallizer flow field is based on the principle of the three theorems of similarity. The basic conditions for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com