Preparation method of defoaming agent in carbon fiber sizing technology and sizing method

A defoamer, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of reducing the comprehensive performance of carbon fiber, defects of the polymer protective layer on the surface of carbon fiber, etc., and achieve the effect of maintaining comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

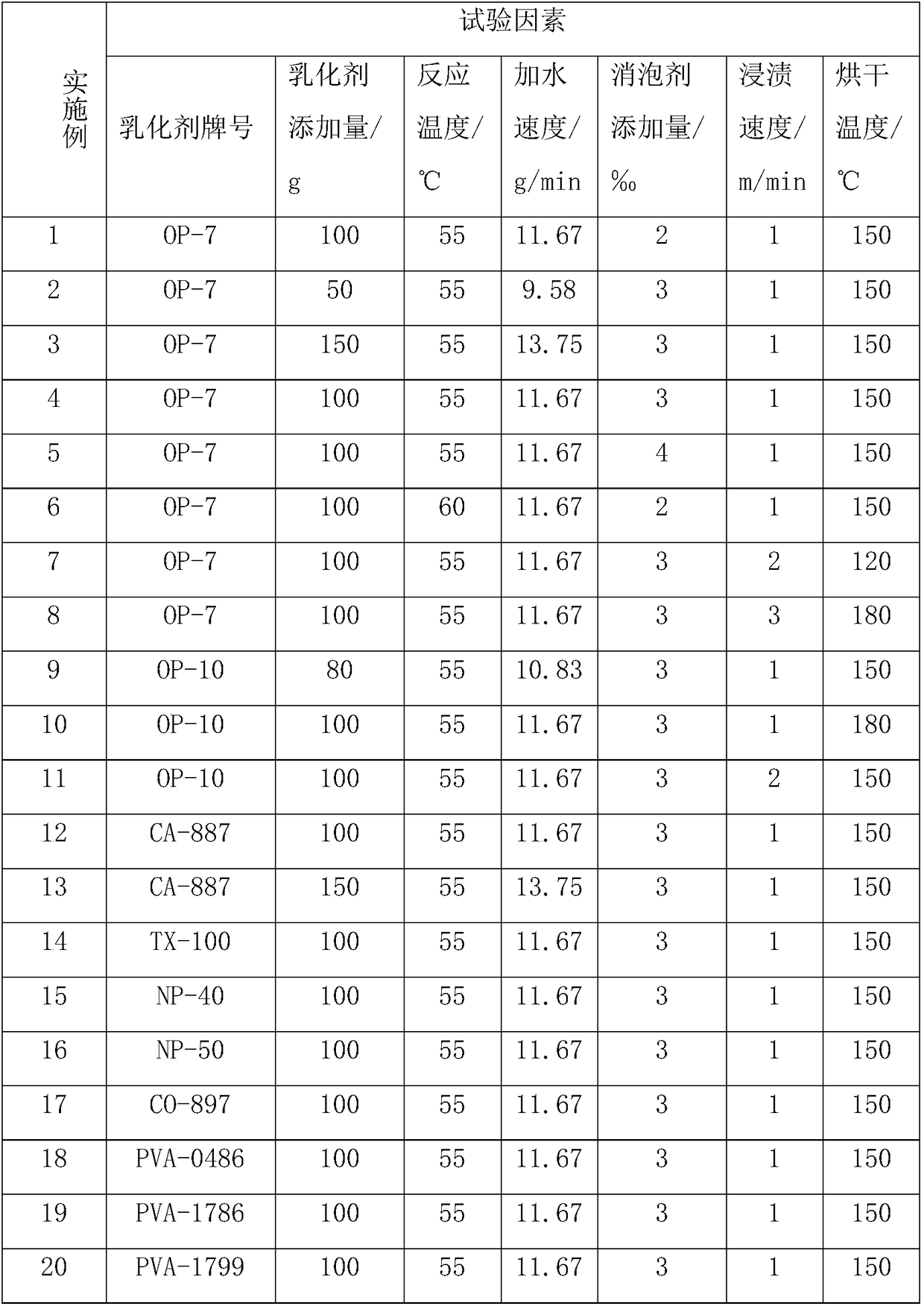

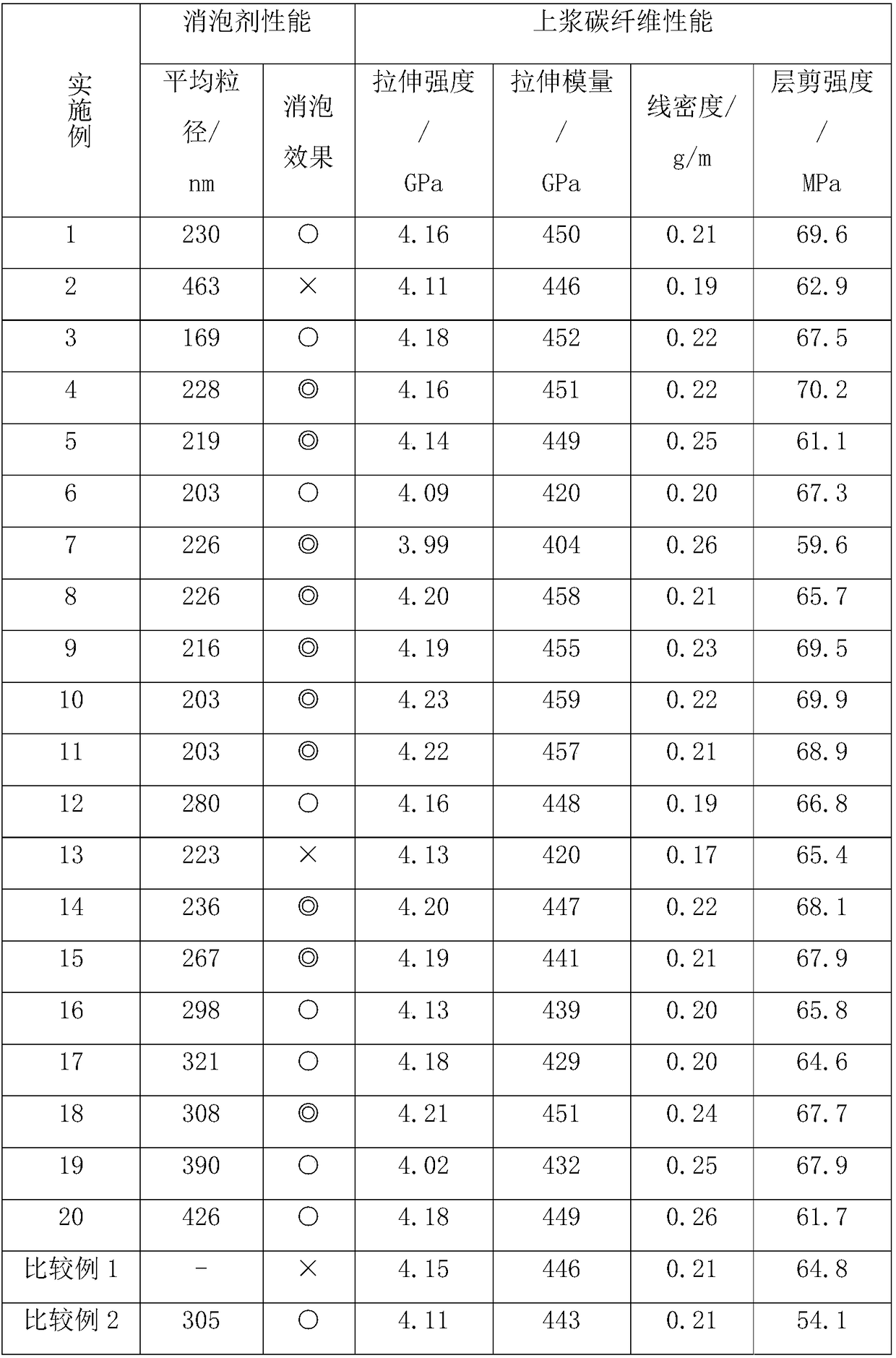

Embodiment 1

[0023] At room temperature, in a four-necked reaction flask equipped with a stirrer, a reflux condenser, a thermometer and a dropping funnel, add 200g of simethicone, 100g of acetone, and 100g of octylphenol polyoxyethylene ether OP-7 in sequence, and react The bottle was stirred and heated to 55°C, and stirred for 1 hour to mix well. 1400 g of deionized water was slowly added dropwise with a dropping funnel, and the dropping time was 2 hours. After the dropwise addition, keep warm for 1 hour, and the temperature is controlled at 55°C. Then cool down to below 40°C and filter the material through 200 mesh screen. A special defoamer for carbon fiber sizing process with a solid content of 20% was obtained.

[0024] Add defoamer according to 2‰ of the total mass ratio of sizing agent in the carbon fiber sizing tank, and observe the defoaming effect after mixing evenly.

[0025] The carbon fiber is expanded to three times the width of the original tow and passes through the stoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com