Axle shaft steel for railway vehicle and production method of axle shaft steel

A technology for railway vehicles and production methods, which is applied in the field of axle steel for railway vehicles and its production, and can solve problems such as low transverse impact energy, magnetic marks on the surface of axle steel, instability, etc., so as to reduce quality objections, reduce production costs, The effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with examples.

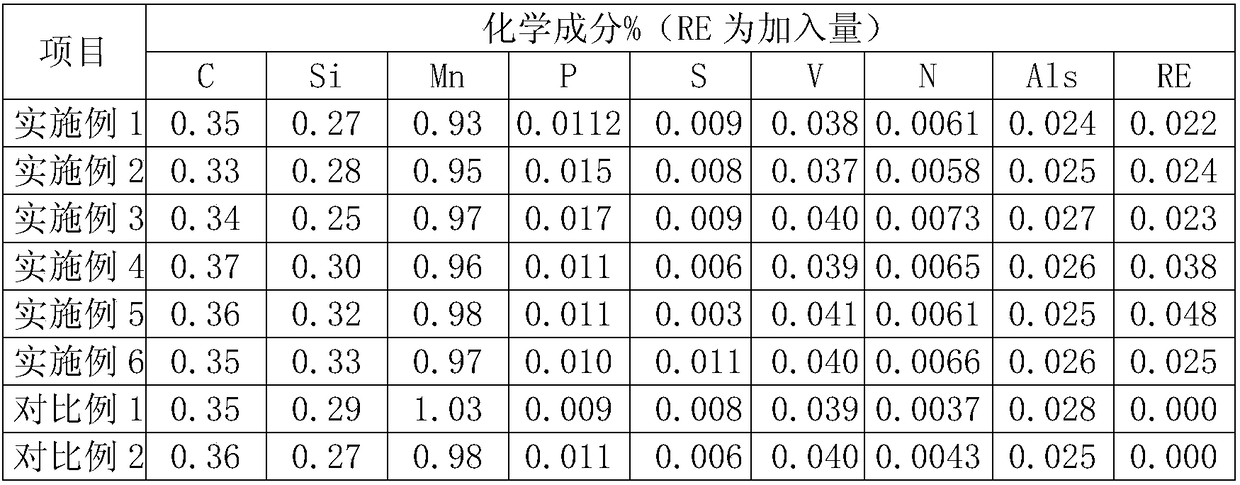

[0034] The chemical components and weight percentages of the axle steels of Examples 1-6 and Comparative Examples 1-2 are shown in Table 1.

[0035] Table 1

[0036]

[0037] The production process steps are as follows:

[0038] 110-ton electric furnace smelting→LF+RH refining→continuous casting→press processing (rolling billet→fast forging machine forging)→rough machining→heat treatment→finish machining→inspection and storage. Among them, in Examples 1 to 4, a lanthanum-cerium rare-earth alloy ingot with a purity of 99% was added before the void breaking at the end of the RH refining treatment. In Examples 5-6, after the RH refining treatment, the lanthanum-cerium rare-earth alloy wire with a purity of 99% is fed, and the argon and soft blowing are weakly blown.

[0039] The heat treatment process parameters of each embodiment and comparative example are shown in Table 2.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com