Preparation method of carbon-coated cobaltous sulfide/cobaltous octosulfide nano particles having multistage porous structure and application thereof

A nanoparticle and carbon coating technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of material capacity attenuation, material shedding, etc., and achieve high utilization rate, large specific surface area, and controllable product morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Solution A: Dissolve cobalt acetate tetrahydrate in 3ml of DMF solution, the concentration of the solute is 0.3mol / L, the solution is kept at a constant temperature of 50°C in a water bath, then add 0.1g of PAN, and stir until the solution is uniform;

[0049] Solution B: Prepare 30ml of a mixed solution of glycerol and isopropanol at a ratio of 1:10 (v / v), stir and mix evenly;

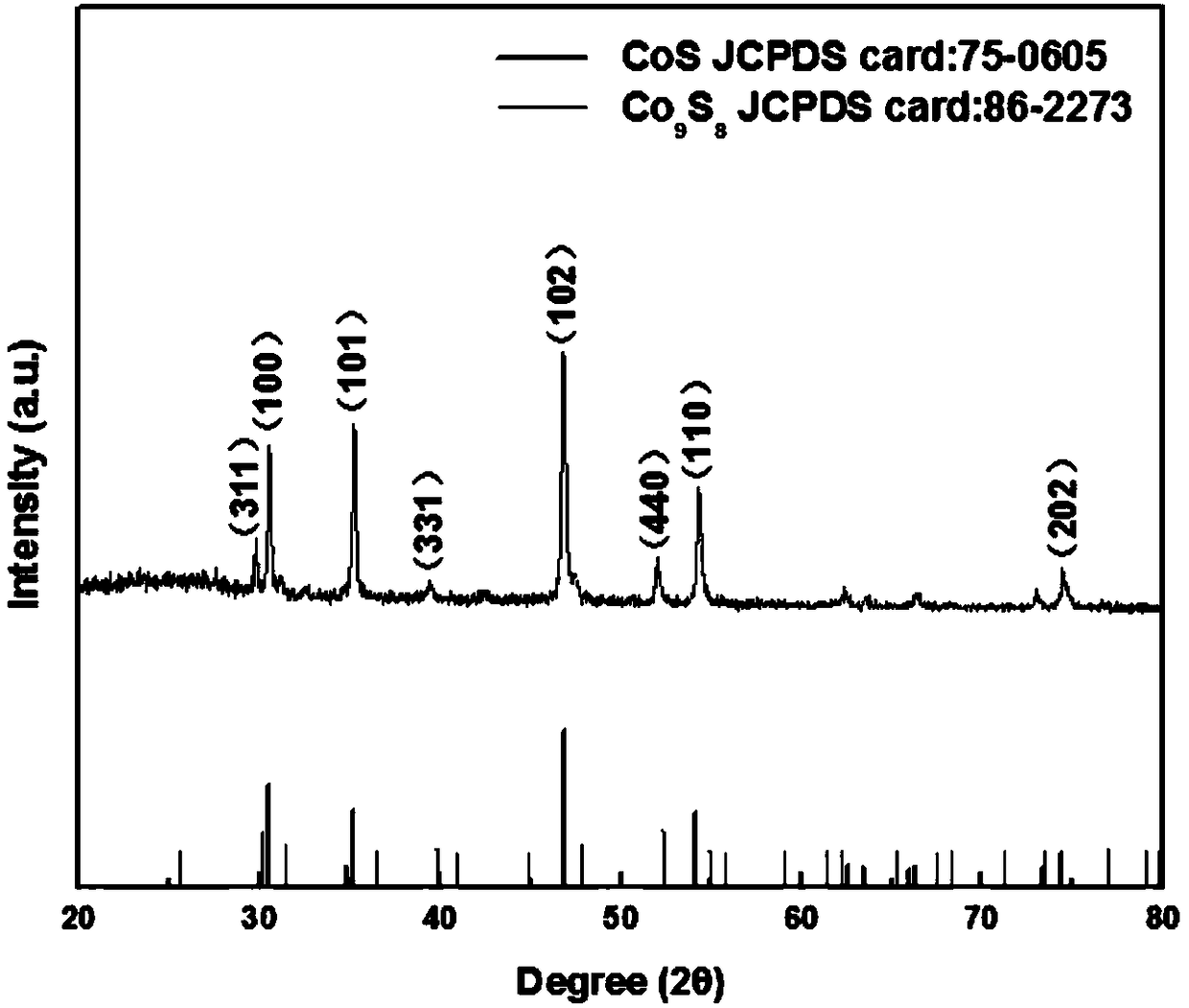

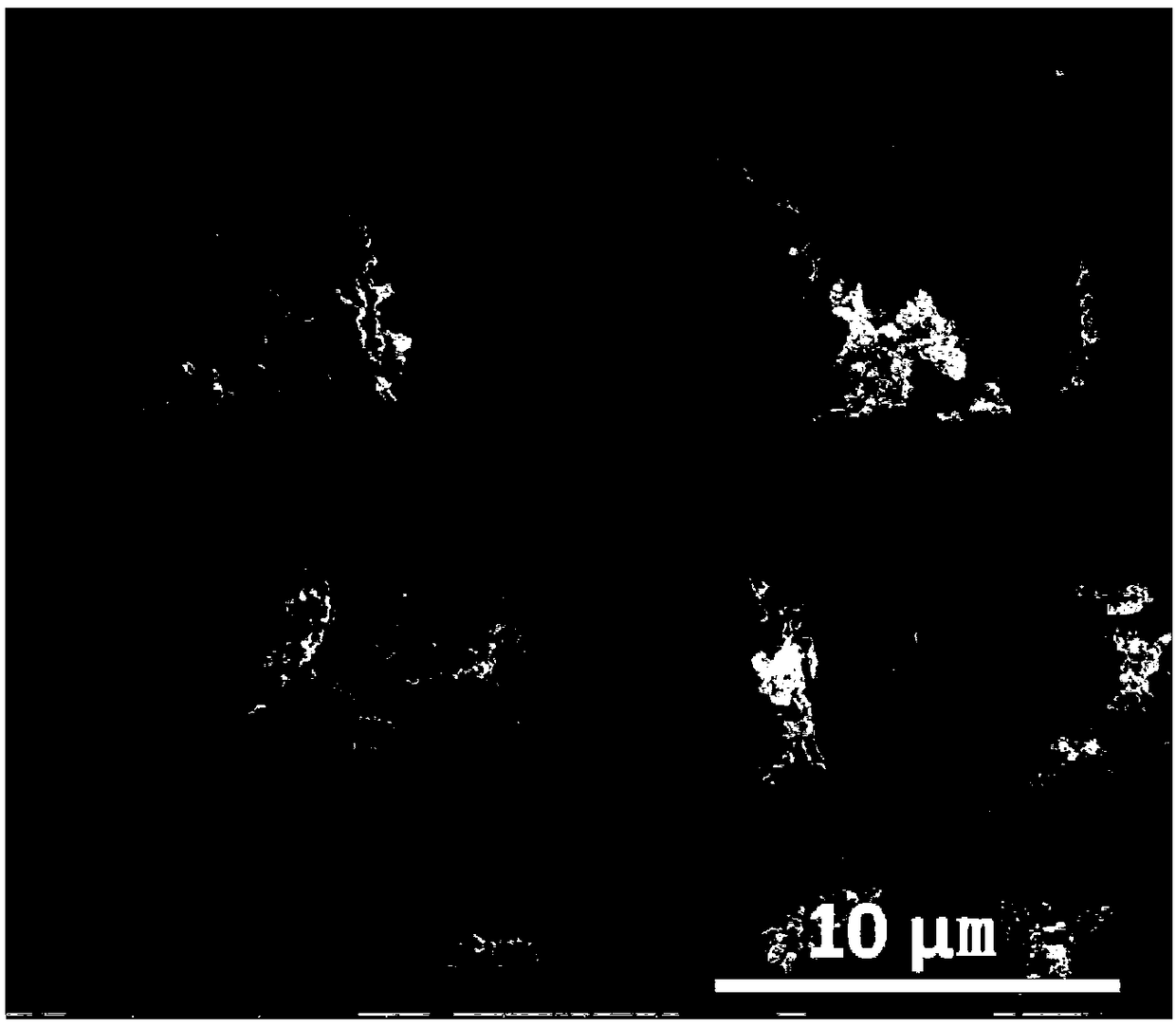

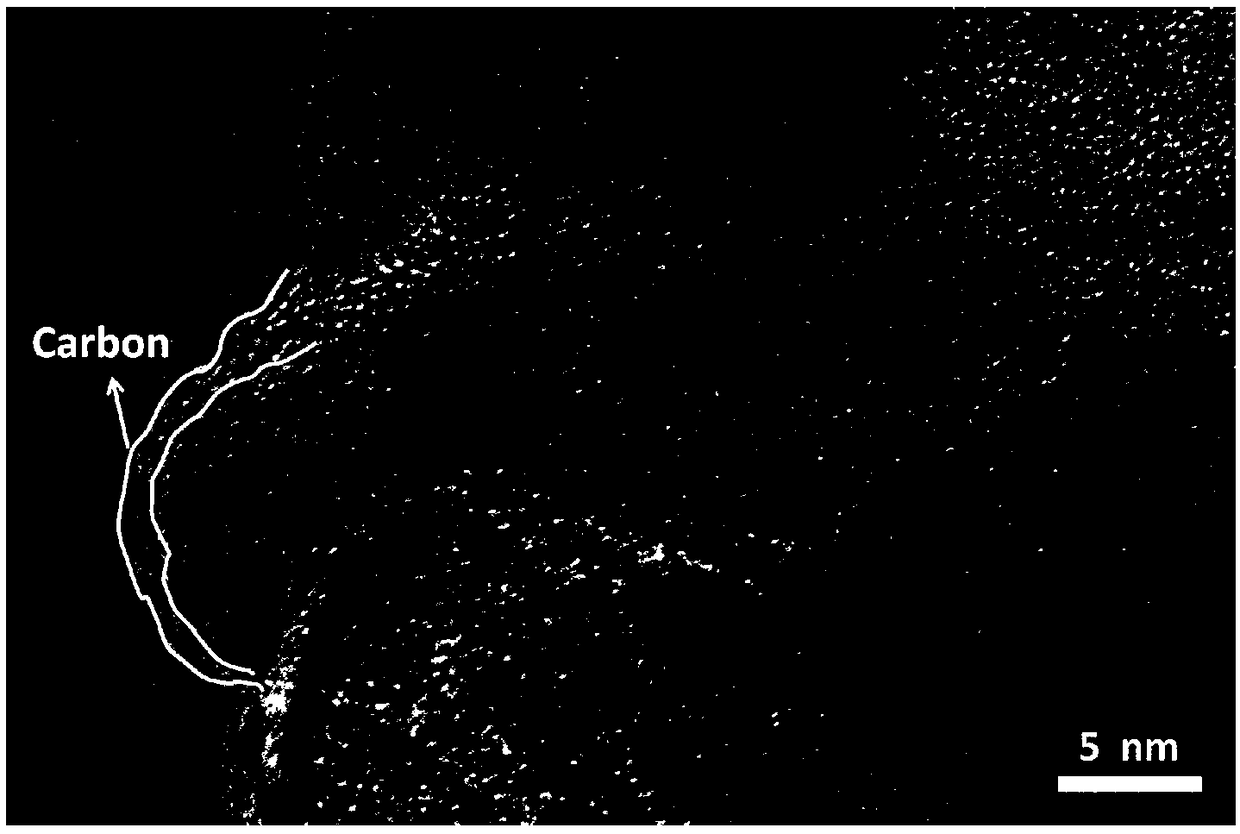

[0050] Add solution A dropwise to solution B at a rate of 0.7mL / min. After the dropwise addition, continue stirring at a speed of 600rmp for 20min, then transfer to a 50ml solvothermal reaction kettle, and solvothermally heat at 180°C for 6h. The resulting product was centrifuged and washed several times with water and ethanol, and then dried at 60°C. According to the ratio of the amount of substance Sulfur source: Cobalt source (N (S) :N (C o ) )=5:1 add sulfur powder as a sulfur source, mix evenly with the dried product, place in a tube furnace to rise to 700°C with a heating rate of 3°C / m...

Embodiment 2

[0053] Solution A: Dissolve cobalt acetate tetrahydrate in 3ml of DMF solution, the concentration of the solute is 0.1mol / L, the solution is kept at a constant temperature of 50°C in a water bath, then add 0.06g of PAN, and stir until the solution is uniform;

[0054] Solution B: Prepare 30ml of a mixed solution of glycerol and isobutanol at a ratio of 1:5 (v / v), stir and mix evenly;

[0055] Add solution A dropwise to solution B at a rate of 0.6mL / min. After the dropwise addition, continue stirring at a speed of 600rmp for 20min, then transfer to a 50ml solvothermal reaction kettle, and solvothermally heat at 180°C for 3h. The resulting product was centrifuged and washed several times with water and ethanol, and then dried at 60°C. According to the ratio of the amount of substance N (S) :N (C o)=5:1 add sulfur powder as a sulfur source, mix it with the dried product evenly, put it in a tube furnace and raise it to 750°C at a rate of 5°C / min, the protective atmosphere is arg...

Embodiment 3

[0057] Solution A: Dissolve cobalt acetate tetrahydrate in 3ml of DMF solution, the concentration of the solute is 0.2mol / L, the solution is kept at a constant temperature of 50°C in a water bath, then add 0.2g of PAN, and stir until the solution is uniform;

[0058] Solution B: Prepare 30ml of a mixed solution of glycerol and ethanol at a ratio of 1:10 (v / v), stir and mix evenly;

[0059] Add solution A dropwise to solution B at a rate of 0.7mL / min. After the dropwise addition, continue stirring at a speed of 600rmp for 20min, then transfer to a 50ml solvothermal reaction kettle, and solvothermally heat at 180°C for 6h. The resulting product was centrifuged and washed several times with water and ethanol, and then dried at 60°C. According to the ratio of the amount of substance N (S) :N (C o ) =3:1 add sulfur powder as sulfur source, mix with the dried product evenly, place in a tube furnace at a heating rate of 3°C / min to 650°C, protect the atmosphere with argon, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com