Carbon nanofiber supported orderly-arranged reduced graphene oxide (RGO) electrode material

A carbon nanofiber and graphene electrode technology, which is applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as poor order, low graphene packing density, and insufficient processing performance , to achieve the effects of preventing agglomeration, high polarizability, and improving charge accumulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of RGO-carbon nanofiber composite

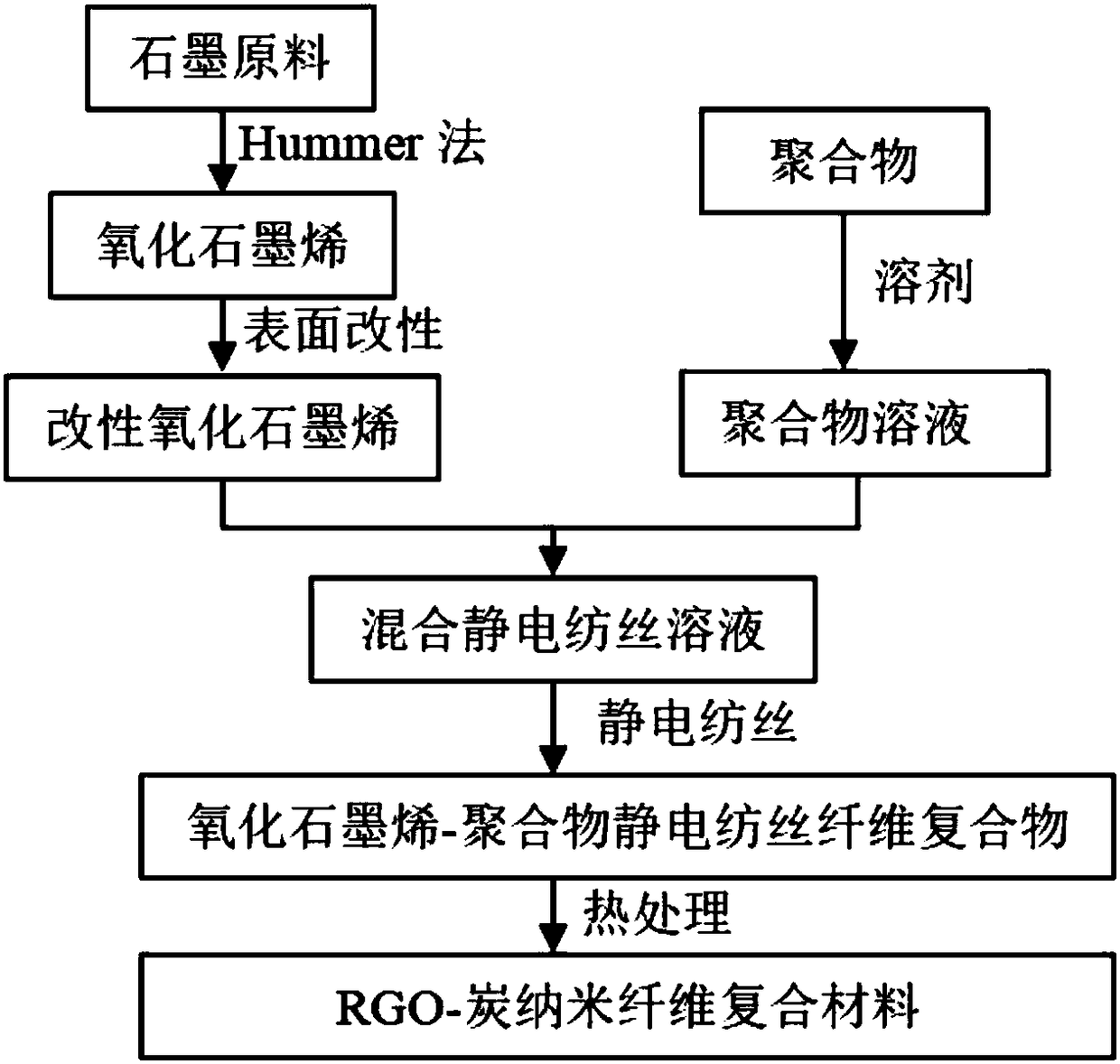

[0042] process such as figure 1 As shown, the specific preparation steps are as follows:

[0043] (1), preparation of surface modified graphene oxide

[0044] Slowly add 10.0g of 5000 mesh natural flake graphite into a 2000mL large beaker filled with 200mL of concentrated sulfuric acid under stirring, keep the temperature at (0±1)℃, then slowly add the mixture of 4g of sodium nitrate and 20g of potassium permanganate , maintain (0 ± 1) ℃ under stirring, 2h to complete the reaction, in (35 ± 3) ℃ constant temperature water bath, keep stirring for 30min, slowly add 460mL of water, let the temperature rise to 98 ℃, at this temperature Maintain for 15 minutes; dilute to 1400mL with warm water, pour a certain amount of 0.5g H 2 o 2 , filtered while hot, fully washed the filter cake with 5wt% HCl until there was no SO in the filtrate 4 2- (with BaC1 2 solution detection), at 50°C at P 2 o 5 In the presence of ...

Embodiment 2

[0052] Example 2 Preparation of RGO-carbon nanofiber composite

[0053] (1), preparation of surface modified graphene oxide

[0054] Take 10.0g of 3000 mesh flake graphite as raw material, add 300.0mL of concentrated sulfuric acid, 5.0g of sodium nitrate, 30.0g of potassium permanganate and 0.5g of H 2 o 2 , using the improved Hummer method to prepare graphene oxide to obtain an aqueous graphene oxide solution with an O / C ratio of 0.3 to 0.5;

[0055] Take the graphene oxide aqueous solution and process it for 10 minutes under the action of ultrasonic waves with a frequency of 80 kHz and a power of 2.0 kW to obtain a graphene oxide solution with a graphene oxide sheet thickness of 10.0 nm to 30.0 nm and a sheet size of 0.1 μm to 2 μm;

[0056]The obtained graphene oxide solution is deacidified and deionized in deionized water using a semipermeable membrane, and the deionized water outside the semipermeable membrane is replaced every 2 hours until the pH of the solution outsi...

Embodiment 3

[0064] Example 3 Preparation of RGO-carbon nanofiber composites

[0065] (1), preparation of surface modified graphene oxide

[0066] Take 10.0g of 1000 mesh flake graphite as raw material, add 400mL of concentrated sulfuric acid, 6.0g of sodium nitrate, 40.0g of potassium permanganate and 0.5g of H 2 o 2 , using the improved Hummer method to prepare graphene oxide to obtain an aqueous graphene oxide solution with an O / C ratio of 0.3 to 0.5;

[0067] Take the graphene oxide aqueous solution and process it for 20 minutes under the action of ultrasonic waves with a frequency of 100 kHz and a power of 3.0 kW to obtain a graphene oxide dispersion solution with a graphene oxide sheet thickness of 10.0 nm to 30.0 nm and a sheet size of 0.1 μm to 2 μm;

[0068] The resulting graphene oxide dispersion solution is deacidified and deionized in deionized water using a semipermeable membrane, and the deionized water outside the semipermeable membrane is replaced every 2 hours until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com