Heat insulating type double-walled corrugated pipe

A double-wall corrugated pipe and heat preservation technology, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, can solve the problems of difficult quality assurance, easy damage of the heat preservation layer, and poor heat preservation effect, so as to achieve good heat preservation performance and improve heat preservation effect , the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

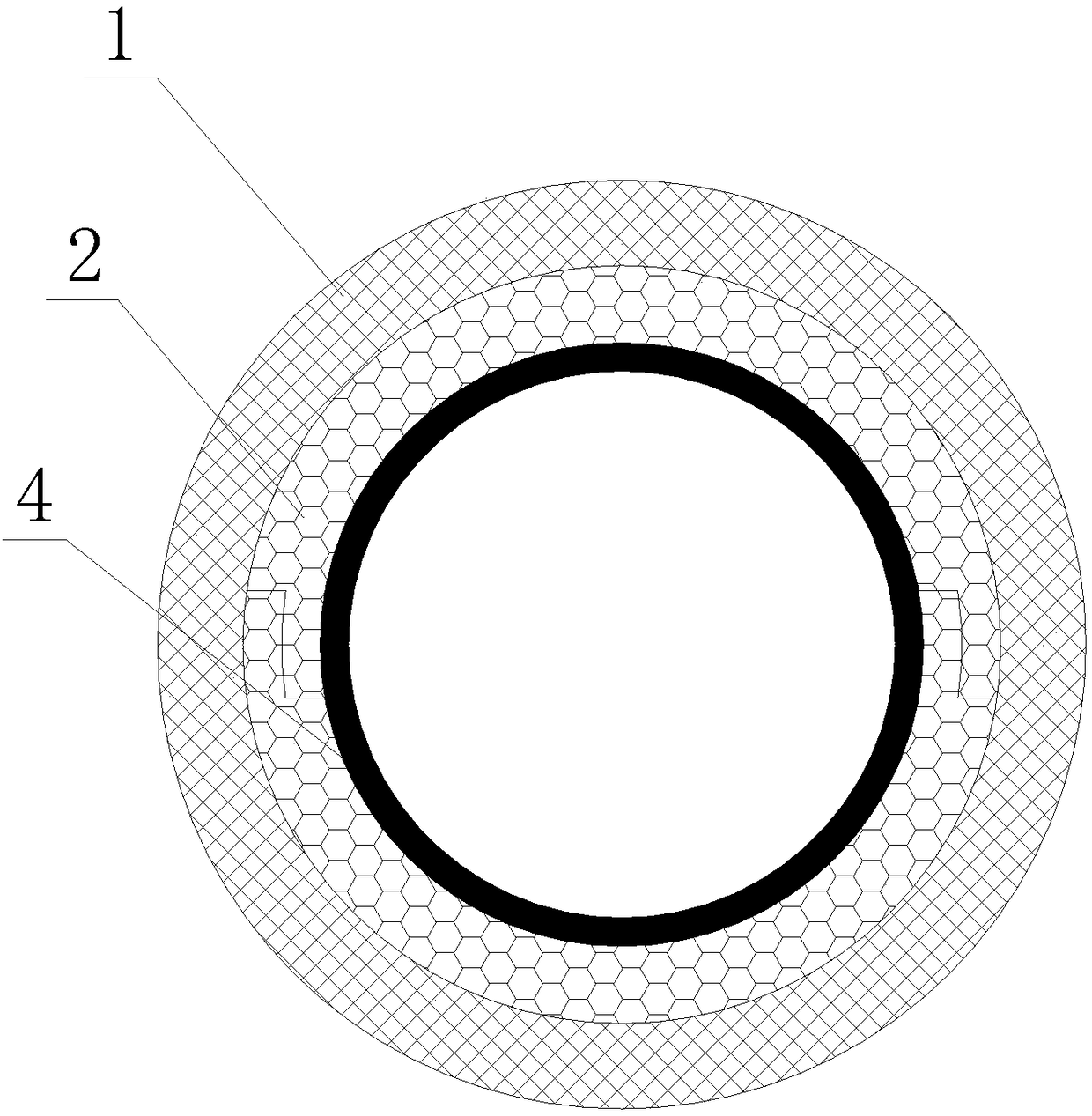

[0022] like figure 1 and figure 2 As shown, what is shown is an embodiment structure of the present invention, denoted as Embodiment A, which includes a double-wall corrugated pipe layer 1 and a vacuum insulation panel insulation layer 2 connected to the double-wall corrugated pipe layer 1, and the vacuum insulation panel insulation layer 2 The layer 2 is connected to the outer surface of the double-wall corrugated pipe layer 1, and also includes a foamed EVA buffer layer 3, and the foamed EVA buffer layer 3 is connected to the outer surface of the thermal insulation layer 2 of the vacuum heat insulation board. The inner surface of the vacuum insulation panel insulation layer 2 has the same curvature as the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com