Thermal deformation and stabilization process of an al-mg-mn-er-zr alloy plate

An alloy sheet and thermal deformation technology, applied in the field of non-ferrous metal alloys, can solve the problems of long-term corrosion resistance, decreased elongation, and cumbersomeness of untested materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

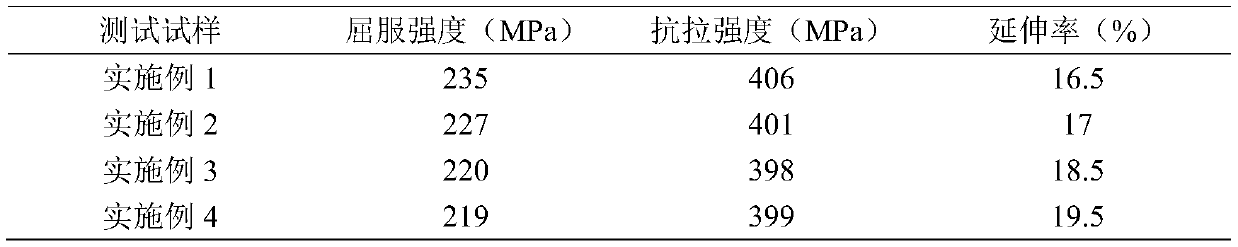

[0017] 1) Percentage by mass: Mg, 5.9%; Mn, 0.84%; Er, 0.2%; Zr, 0.09%; Fe-1 , air cooled to room temperature.

[0018] 2) Perform stabilization annealing at 240° C. for the hot-rolled sheet obtained through step 1, and the annealing time is 48 hours. Air cool to room temperature. The tensile properties of the stabilized plates were tested, and the intergranular corrosion and exfoliation corrosion of the alloy before and after sensitization (100°C / 7 days) were tested according to American standards ASTM G66 and ASTM G67. See Table 1 for tensile properties and Table 2 for corrosion properties.

Embodiment 2

[0023] 1) Percentage by mass: Mg, 5.9%; Mn, 0.84%; Er, 0.2%; Zr, 0.09%; Fe-1 , air cooled to room temperature.

[0024] 2) Perform stabilization annealing at 260° C. for the hot-rolled sheet obtained in step 1), and the annealing time is 10 h. Air cool to room temperature. The tensile properties of the stabilized plates were tested, and the intergranular corrosion and exfoliation corrosion of the alloy before and after sensitization (100°C / 7 days) were tested according to American standards ASTM G66 and ASTM G67. See Table 1 for tensile properties and Table 2 for corrosion properties.

Embodiment 3

[0029] 1) Percentage by mass: Mg, 5.9%; Mn, 0.84%; Er, 0.2%; Zr, 0.09%; Fe-1 , air cooled to room temperature.

[0030] 2) Perform stabilization annealing at 280° C. for the hot-rolled sheet obtained in step 1), and the annealing time is 6 hours. Air cool to room temperature. The tensile properties of the stabilized plates were tested, and the intergranular corrosion and exfoliation corrosion of the alloy before and after sensitization (100°C / 7 days) were tested according to American standards ASTM G66 and ASTM G67. See Table 1 for tensile properties and Table 2 for corrosion properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com