Isometric spherical magnesium material as well as preparation method thereof and application in producing dispersion-type magnesium ventilated plug

A breathable plug and spherical technology, which is applied to the field of radial spherical magnesium material and its preparation, can solve the problems of insufficient air blowing strength, poor ventilation effect of the breathable plug, unstable air supply effect, etc., and achieves good effect, good ventilation, Channels have a uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

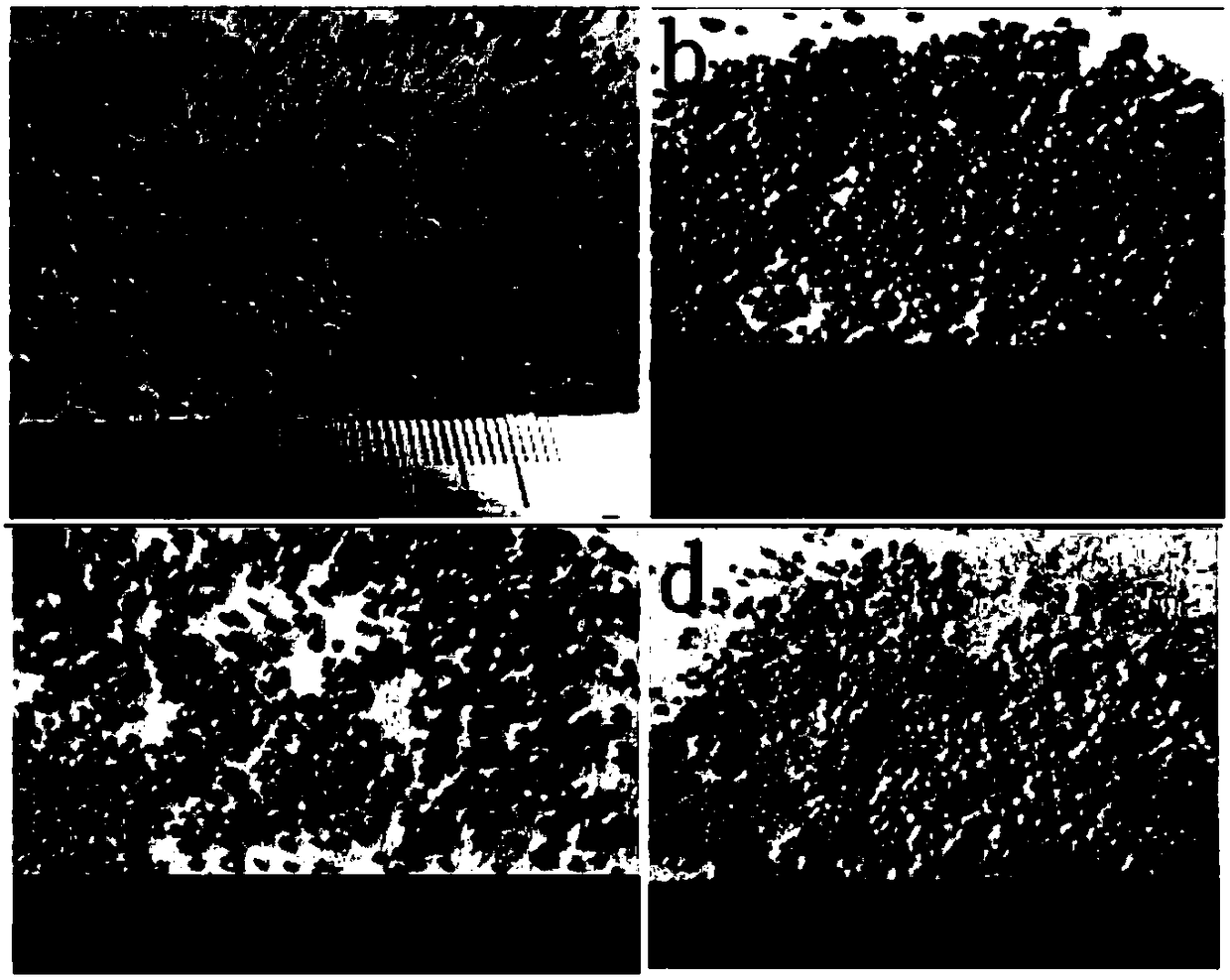

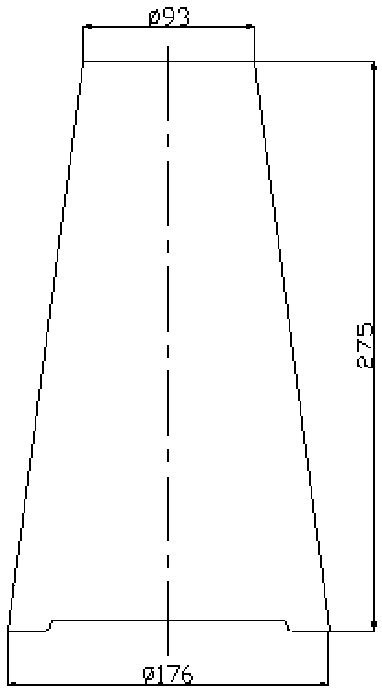

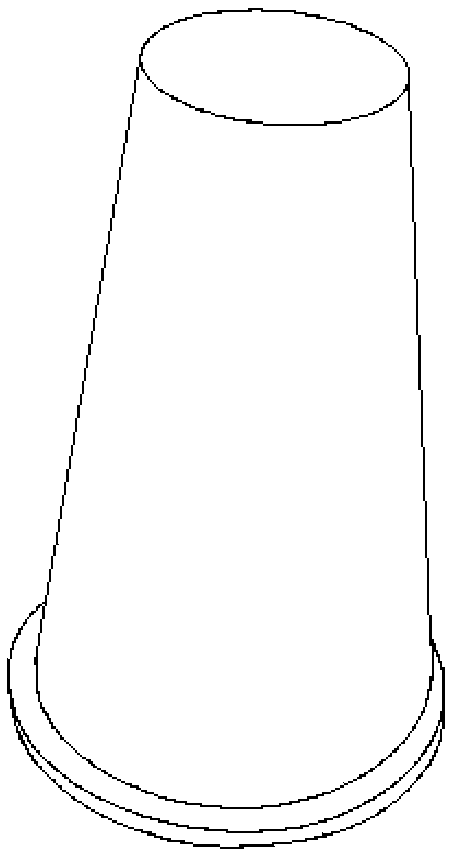

Image

Examples

Embodiment 1

[0046] Example 1 A kind of equal-diameter spherical magnesium raw material for producing diffused magnesium gas vent plug

[0047] (1) Made from the following raw materials by weight percentage:

[0048]

[0049] (2) The preparation method is as follows:

[0050] 1. Slowly add dextrin to water at 90-100°C, stir evenly to fully dissolve the dextrin into the water, and let it cool for later use;

[0051] 2. Put 97% high-purity magnesia with a particle size of 40 mesh, 100 mesh, and 200 mesh and 95% lightly burned magnesium powder with a particle size of 200 mesh into a high-speed mixer, mix at a low speed for 1.5 minutes, and set the operating parameters of the high-speed mixer as follows: granulation The revolution speed of the machine turntable is 36r / min, and the speed of the high-speed rotor is 288r / min;

[0052] 3. Add the dextrin aqueous solution obtained in step 1, mix at high speed for 8 minutes, and set the operating parameters of the high-speed granulation equipme...

Embodiment 2

[0056] Example 2 A kind of equal-diameter spherical magnesium raw material for producing diffused magnesium gas vent plug

[0057] (1) Made from the following raw materials by weight percentage:

[0058]

[0059] (2) The preparation method is as follows:

[0060] 1. Slowly add dextrin to water at 90-100°C, stir evenly to fully dissolve the dextrin into the water, and let it cool for later use;

[0061]2. Put 97% high-purity magnesia with a particle size of 40 mesh, 100 mesh, and 200 mesh and 95% lightly burned magnesium powder with a particle size of 200 mesh into a high-speed mixer, and mix at a low speed for 2 minutes. The operating parameters of the high-speed mixer are set as: granulation The revolution speed of the machine turntable is 36r / min, and the speed of the high-speed rotor is 288r / min;

[0062] 3. Add the dextrin aqueous solution obtained in step 1, mix at high speed for 7 minutes, and set the operating parameters of the high-speed granulation equipment as f...

Embodiment 3

[0067] Example 3 A kind of equal-diameter spherical magnesium raw material for producing diffused magnesium gas vent plug

[0068] (1) Made from the following raw materials by weight percentage:

[0069]

[0070] (2) The preparation method is as follows:

[0071] 1. Slowly add dextrin to water at 90-100°C, stir evenly to fully dissolve the dextrin into the water, and let it cool for later use;

[0072] 2. Put 97% high-purity magnesia with a particle size of 40 mesh, 100 mesh, and 200 mesh and 95% lightly burned magnesium powder with a particle size of 200 mesh into a high-speed mixer, mix at a low speed for 1 minute, and set the operating parameters of the high-speed mixer as follows: granulation The revolution speed of the machine turntable is 36r / min, and the speed of the high-speed rotor is 288r / min;

[0073] 3. Add the dextrin aqueous solution obtained in step 1, and mix at high speed for 6 minutes. The operating parameters of the high-speed granulation equipment are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com