Landfill leachate high-performance denitrification system and denitrification process thereof

A landfill leachate and denitrification technology, applied in the field of denitrification systems, can solve problems such as loss of anoxic conditions, affecting nitrification and denitrification effects, and large return flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

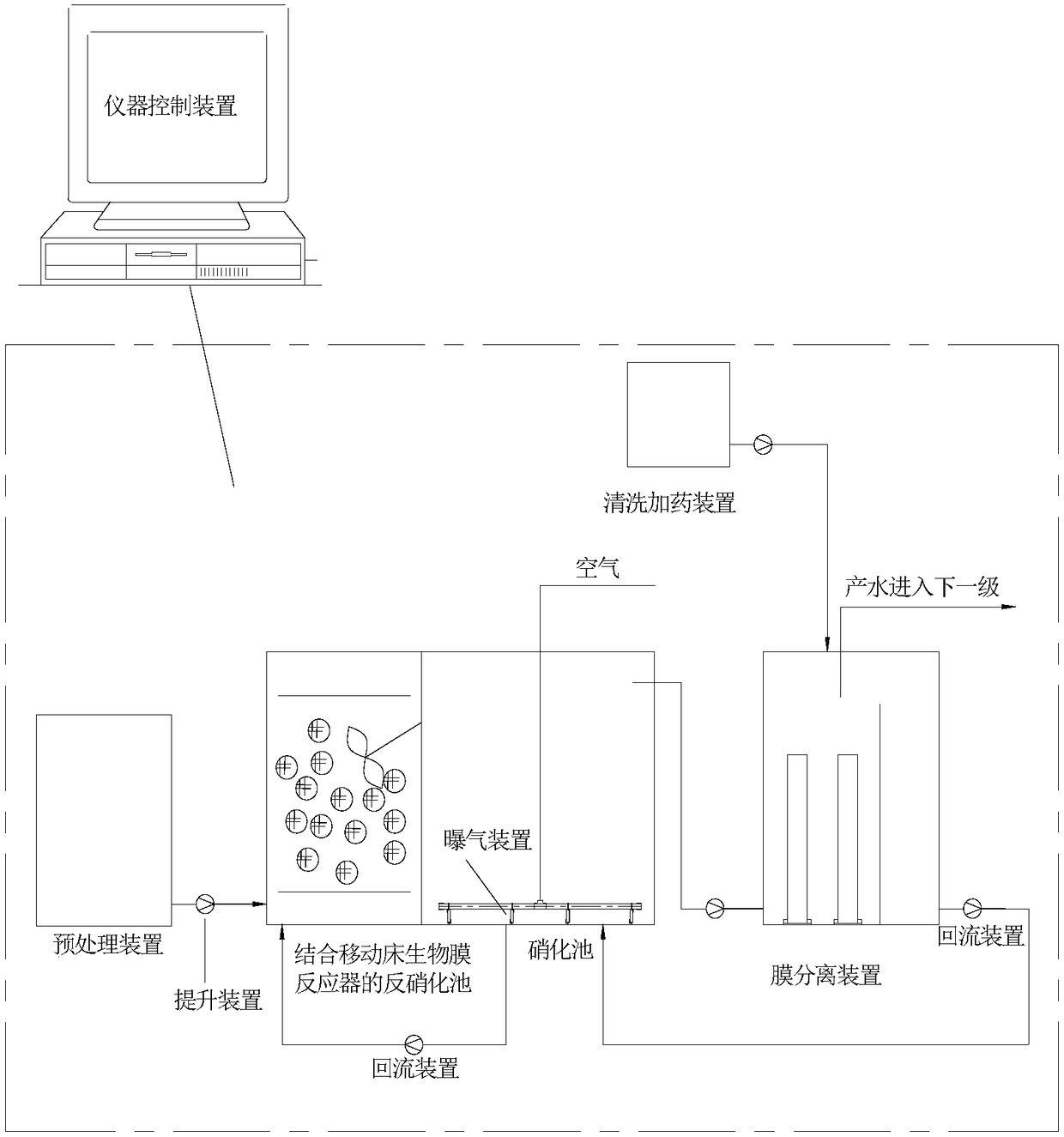

[0084] Example 1 High-efficiency denitrification system for landfill leachate and its denitrification process

[0085] Use environment: for the main removal of organic matter, medium denitrification, sufficient front-end carbon source (such as incineration plant leachate), and low requirements for total nitrogen in effluent

[0086] Core structure: as attached figure 1 As shown, the denitrification tank combined with the moving bed biofilm reactor is placed in the nitrification tank; the reflux device includes a sludge reflux device and a nitrification liquid reflux device, and the sludge reflux device connects the ultrafiltration membrane with the nitrification tank and the nitration liquid reflux The device is connected to the nitrification tank and the denitrification tank combined with the moving bed biofilm reactor, so that the sludge passed through the ultrafiltration membrane is returned to the nitrification tank, and the nitrification liquid is returned to the denitrif...

Embodiment 2

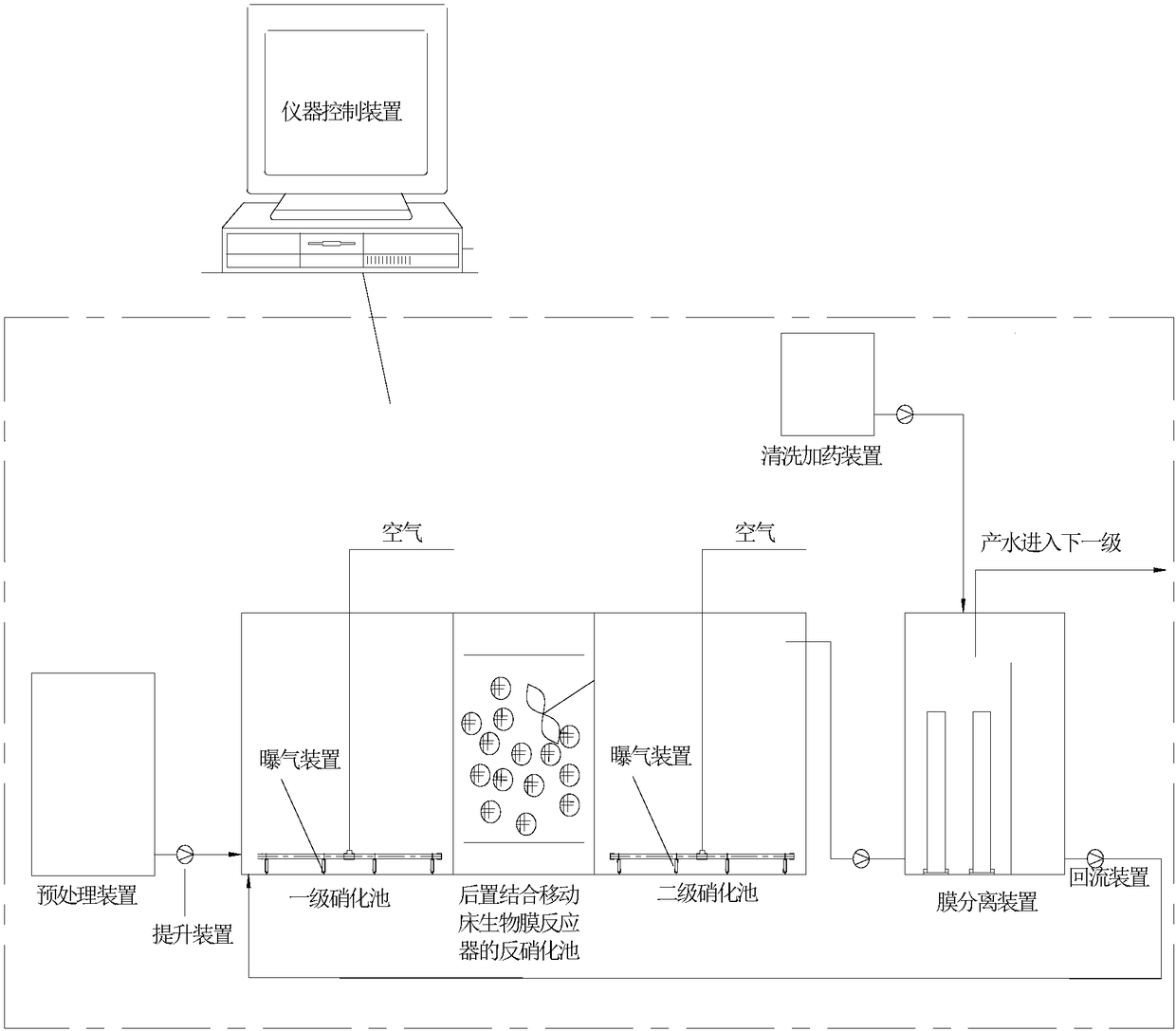

[0088] Example 2 High-efficiency denitrification system for landfill leachate and its denitrification process

[0089] Application environment: Mainly remove organic matter, moderate denitrification, insufficient front-end carbon source, such as landfill leachate, effluent does not have high requirements for total nitrogen

[0090] Core structure: as attached figure 2 As shown, the nitrification tank includes a first-level nitrification tank and a second-level nitrification tank, and the denitrification tank combined with the moving bed biofilm reactor is arranged between the first-level nitrification tank and the second-level nitrification tank; the reflux device is sludge The backflow device is connected to the ultrafiltration membrane and the primary nitrification tank, so as to return the sludge and nitrification liquid passed through the ultrafiltration membrane to the primary nitrification tank.

[0091] Process: Sewage first passes through a first-level nitrification ...

Embodiment 3

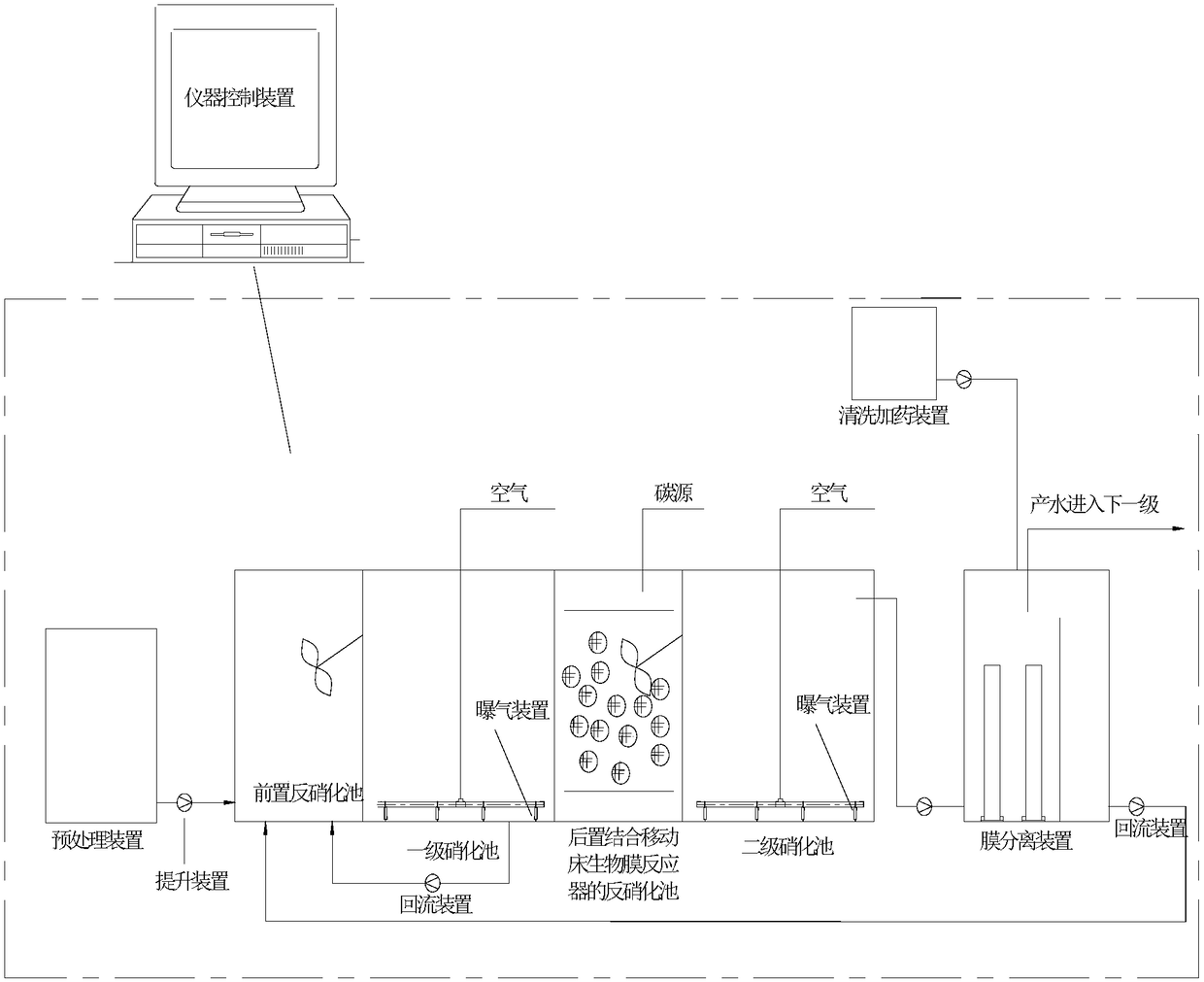

[0092] Example 3 High-efficiency denitrification system for landfill leachate and its denitrification process

[0093] Application environment: Removing organic matter requires high total nitrogen in the effluent. No matter whether the front-end carbon source is sufficient, it is required to strengthen nitrification and denitrification denitrification. Nitrogen <10mg / L.

[0094] Core structure: as attached image 3 As shown, the nitrification tank includes a primary nitrification tank and a secondary nitrification tank, and the denitrification tank includes a front denitrification tank and a post denitrification tank, and the denitrification tank combined with a moving bed biofilm reactor is a post denitrification tank Denitrification tank; use the pre-denitrification tank and the post-denitrification tank before and after the first-level nitrification tank; set the second-level nitrification tank after the post-denitrification tank; the return device includes a nitrification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com