Processing equipment for separating waste water by superconducting magnet

A wastewater treatment and magnetic separation technology, which is applied in the fields of magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem that magnetic attraction cannot be separated, and achieves no need for frequent maintenance, high efficiency and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

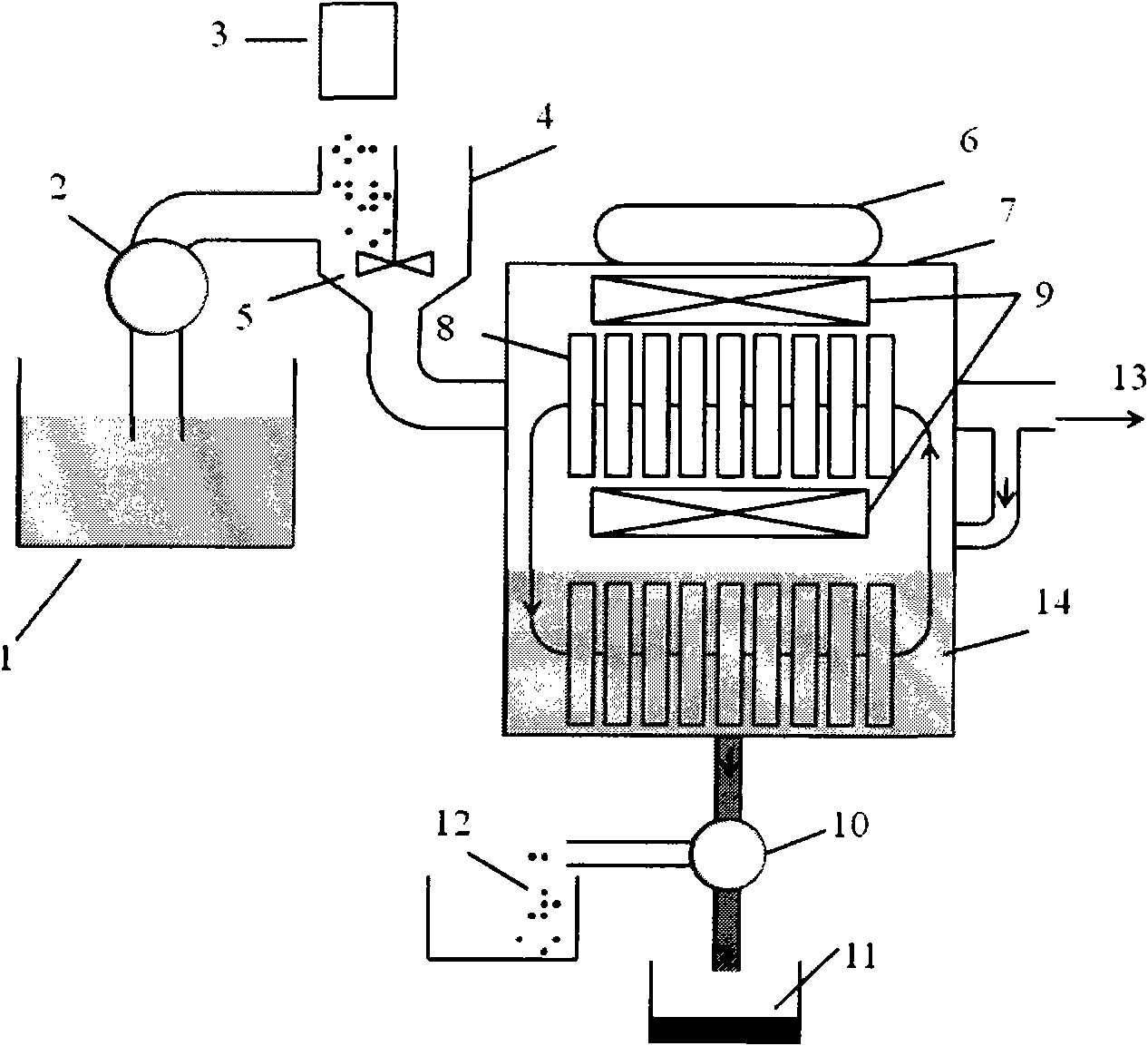

[0033] Such as figure 1 As shown, the magnetic separation wastewater treatment device of this embodiment includes a magnetic seed and flocculant dispenser 3 , a mixer 4 , a superconducting magnetic separator 7 and a recoverer 10 . The magnetic seed and flocculant feeder 3 is used to feed magnetic seeds and flocculant to the mixer at a certain rate. The mixer 4 is connected with a water inlet pipe for fully mixing the magnetic seeds and flocculant with the wastewater, and the mixer 4 has a stirring blade 5 in it. The water inlet pipe of the mixer 4 can be connected with a water pump 2 for pumping waste water from the waste water pool 1 into the mixer 4 . One end of the magnetic separator is connected to the mixer 4 through a pipeline, and the other end is connected to a water outlet pipe, and the water outlet pipe has a water outlet 13 . The superconducting magnetic separator 7 includes a refrigerator 6, a superconducting magnet 9, and a wastewater treatment pipeline placed i...

Embodiment 2

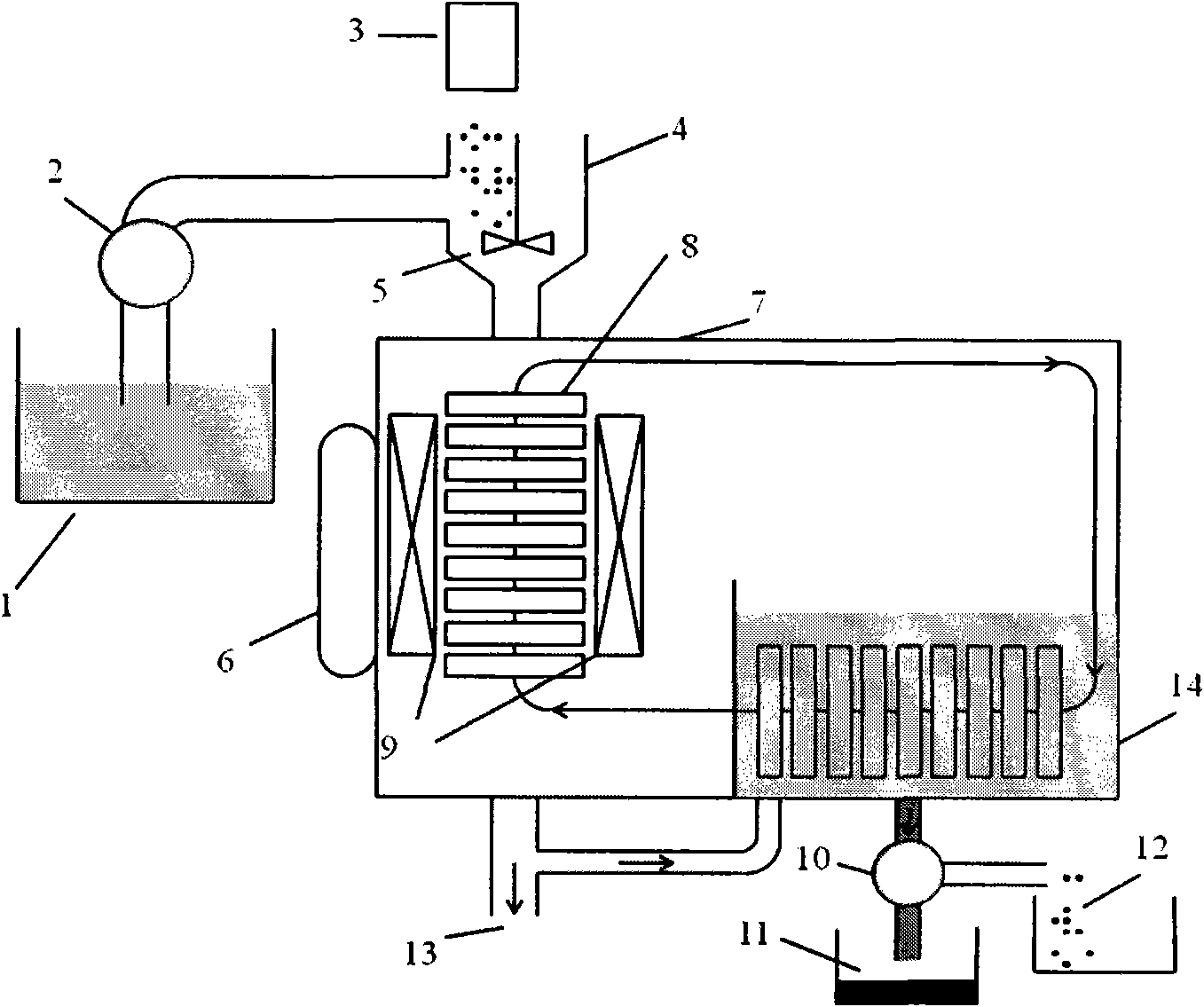

[0053] The magnetic separation wastewater treatment device of this embodiment is basically the same as that of Embodiment 1, except that a vertical structure (such as figure 2 shown). This embodiment is a vertical structure, which is suitable for the purification treatment of oilfield tertiary oil recovery reinjection water. In a vertical structure, clean sieve plates enter the wastewater treatment pipeline from bottom to top.

[0054] The common feature of Examples 1 and 2 is that the sieve plate is used to absorb pollutants, and the internal resistance of the magnetic separator is small, which is suitable for treating wastewater with a large flow rate and a high content of suspended solids.

[0055] The start-up steps and wastewater treatment process of the magnetic separation wastewater treatment device in this embodiment are consistent with those in Embodiment 1.

[0056] According to the procedure of this embodiment, the purification experiment was carried out three ti...

Embodiment 3

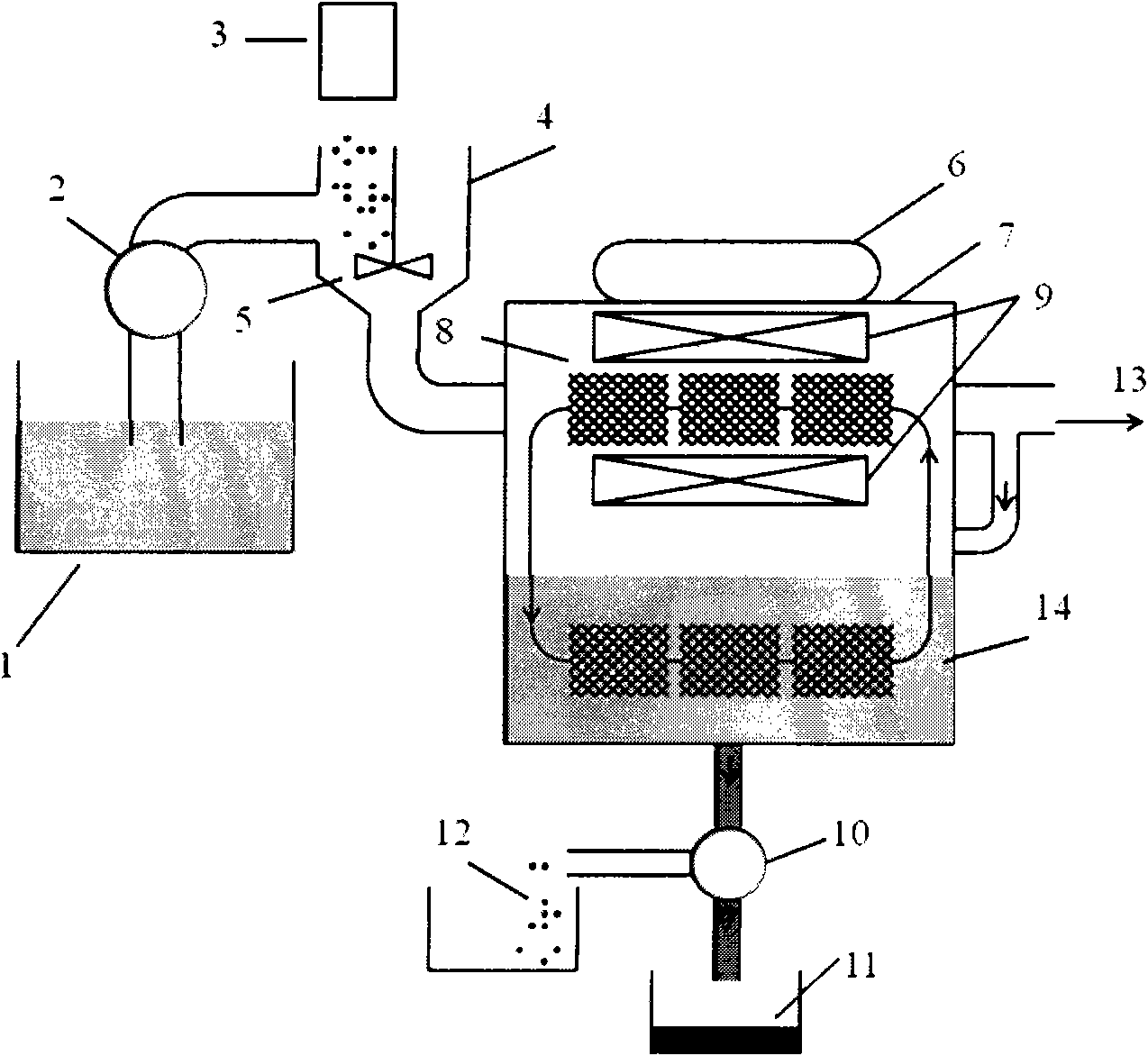

[0058] The magnetic separation wastewater treatment device of this embodiment is as image 3 shown. The magnetic separation wastewater treatment device of this embodiment is basically the same as that of Embodiment 1, except that the magnetic separator of this embodiment uses steel wool instead of a sieve plate for filtration. The steel wool is filled in the wastewater treatment pipeline of the magnetic separator, and the steel wool is twisted and wound by steel wire made of ferritic stainless steel. The wire diameter of the steel wool is 0.05-1 mm. This embodiment may have multiple segments of steel wool, and the distance between two adjacent segments of steel wool is 1 / 3 to 1 / 2 of the length of each segment of steel wool. In this embodiment, the conveying mechanism is used to continuously convey the clean steel wool into the magnetic separator, and continuously remove the steel wool that has absorbed the pollutant flocs from the magnetic separator. The cleaning mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com