A kind of carbon sponge and its preparation method and pressure sensor

A technology of carbon sponge, pressure, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

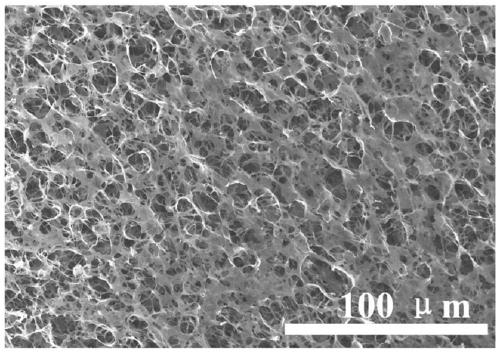

[0191] like Figure 14 Shown, the present invention also provides a kind of preparation method of omnidirectional compressible superelastic carbon sponge, comprises the following steps:

[0192] Step 1, dispersing the additive and graphene oxide into a solvent to form a mixed solution of graphene oxide and additive.

[0193] Step 2, drying the mixed solution to obtain an additive-containing graphene oxide sponge.

[0194] Step 3, heat-treat the additive-containing graphene oxide sponge at high temperature under the protection of an inert gas to obtain a carbon sponge or a full carbon sponge.

[0195] Specifically, the additive is one or more of small molecule organic acids. Preferably, the additive is one or more of ascorbic acid, citric acid, tartaric acid, lactic acid and benzoic acid. The solvent is water and an organic solvent for dispersing the additive and graphene oxide. Preferably, the solvent is one or a mixture of water, ethanol, acetone, dimethylformamide, and c...

specific Embodiment 1

[0210] Step (a) disperse 15 parts by mass of graphene oxide and 45 parts by mass of citric acid into 400 parts by mass of water to form graphene oxide and additive dispersion.

[0211] Step (b) Injecting the graphene oxide and citric acid dispersion into a hollow spherical mold for freeze-drying to obtain a hollow spherical additive-containing graphene oxide sponge.

[0212] Step (c) heat-treating the hollow spherical additive-containing graphene oxide sponge under the protection of a nitrogen atmosphere at 400° C. for 4 hours to obtain a hollow spherical carbon sponge.

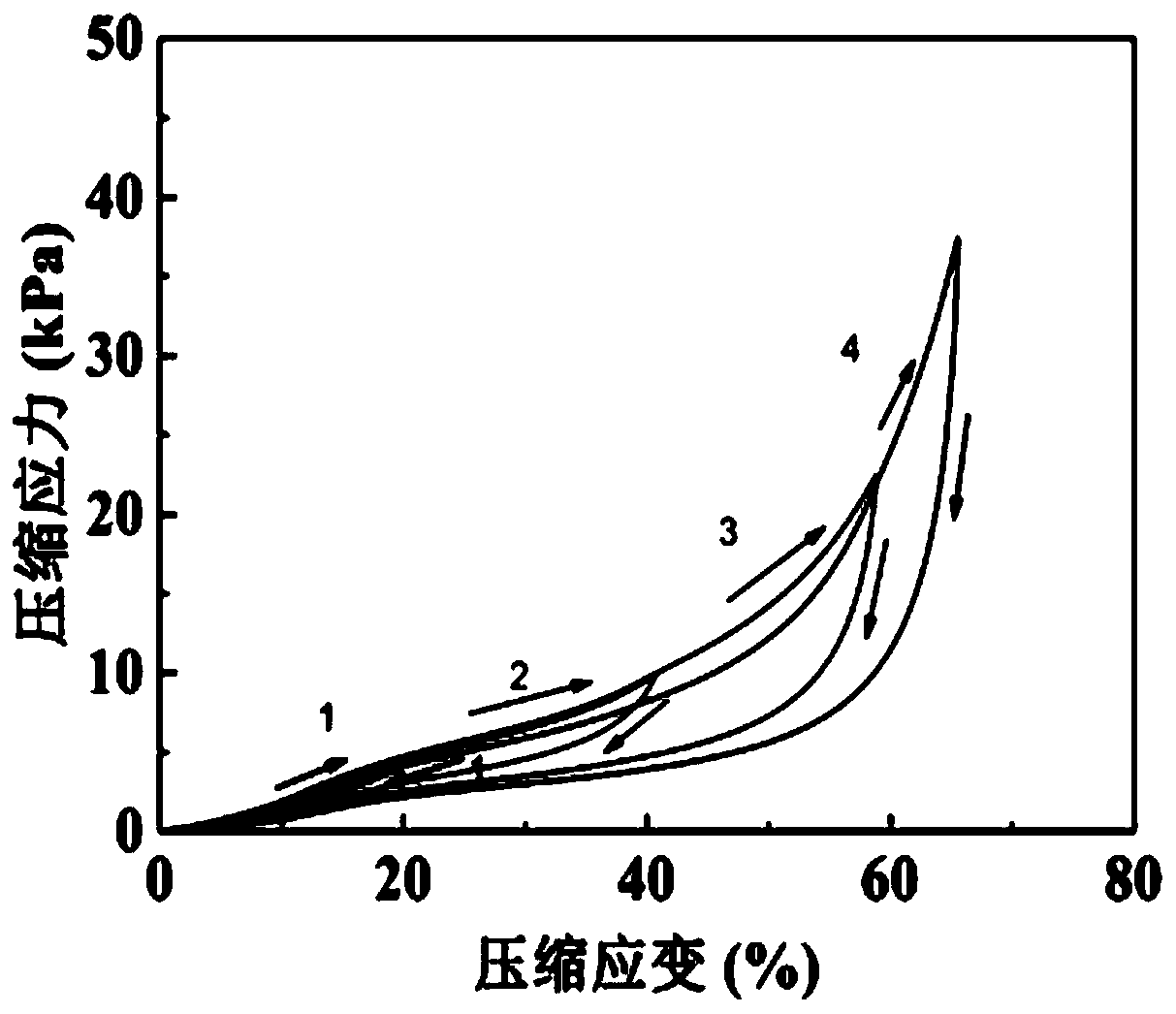

[0213] The hollow spherical carbon sponge graphene obtained by the method accounts for 45%, and the amorphous carbon accounts for 55%. The atomic percentage of oxygen element is 15%, which is a slightly reduced carbon sponge. It has superelasticity in all directions, and the recoverable compressive strain in different directions is 90%-99%. Strength greater than 450kPa. The density is 8.5mg / cm 3 , Conduct...

specific Embodiment 2

[0216] Step (a) disperse 45 parts by mass of graphene oxide into 450 parts by mass of water to form graphene oxide and additive dispersion.

[0217] Step (b) injecting the graphene oxide dispersion liquid into a cuboid mold for supercritical drying to obtain a cuboid graphene oxide sponge, the proportion of additives is 0%, and the proportion of graphene oxide is 100%.

[0218] Step (c) heat-treating the rectangular parallelepiped graphene oxide sponge at 800° C. for 4 hours under the protection of a nitrogen atmosphere to obtain a rectangular parallelepiped carbon sponge.

[0219] The carbon sponge graphene obtained by the method accounts for 100% and does not contain amorphous carbon. The atomic percentage of oxygen element is 60%, which is a slightly reduced carbon sponge. Without superelasticity, the recoverable strain is 0%, and the density is 3.5mg / cm 3 . Conductance is less than 70S / m.

[0220] In this example, the additive is a small molecule organic acid; the rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com