Carbon aerogel and preparation method thereof, and pressure sensor

A carbon aerogel, pressure technology, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0145] Such as Figure 13 , the preparation method of omnidirectional compressible superelastic carbon airgel, comprises the following steps: 1) disperse additive and graphene oxide in solvent to form graphene oxide and additive mixed solution; 2) described mixed solution is dried, Obtaining the graphene oxide aerogel containing the additive; 3) heat-treating the graphene oxide aerogel containing the additive at high temperature under the protection of an inert gas to obtain a carbon aerogel or an all-carbon aerogel.

[0146] Wherein the additive is one or more of monosaccharides, disaccharides, oligosaccharides or polysaccharides;

[0147] Preferably, the monosaccharide is one or more of glucose, fructose, galactose and ribose;

[0148] Preferably, the disaccharide is one or more of maltose, sucrose and lactose;

[0149] Preferably, the oligosaccharide is one or more of raffinose and stachyose;

[0150] Preferably, the polysaccharide is one or more of starch, cellulose, glyc...

specific Embodiment 1

[0175] Step (a) disperse 10 mass parts of graphene oxide and 40 mass parts of sucrose into 500 mass parts of water to form graphene oxide and additive dispersion.

[0176] Step (b) injecting the graphene oxide and sucrose dispersion into a hollow spherical mold for freeze-drying to obtain a hollow spherical additive-containing graphene oxide airgel.

[0177] Step (c) heat-treating the hollow spherical additive-containing graphene oxide airgel at 600° C. for 4 hours under the protection of a nitrogen atmosphere to obtain a hollow spherical carbon airgel.

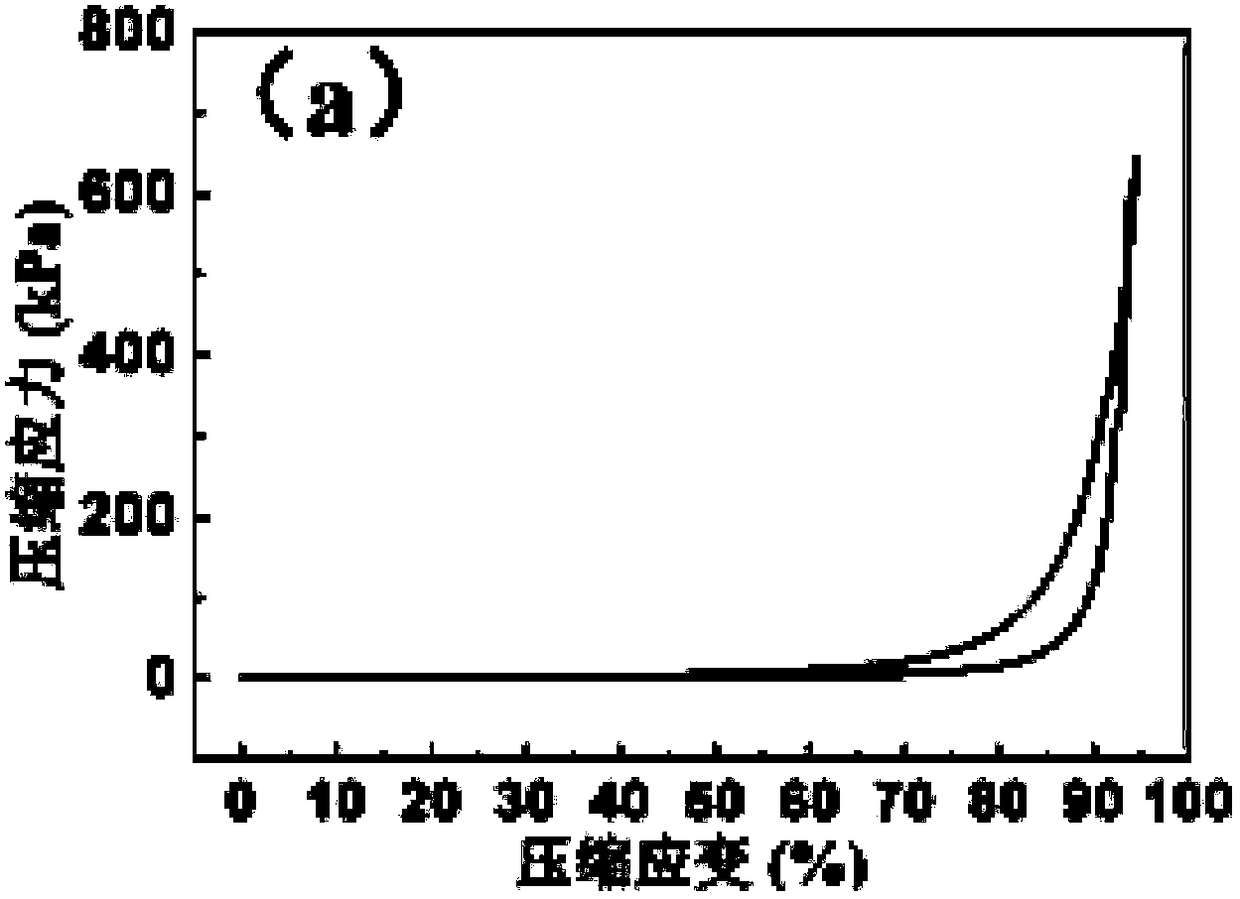

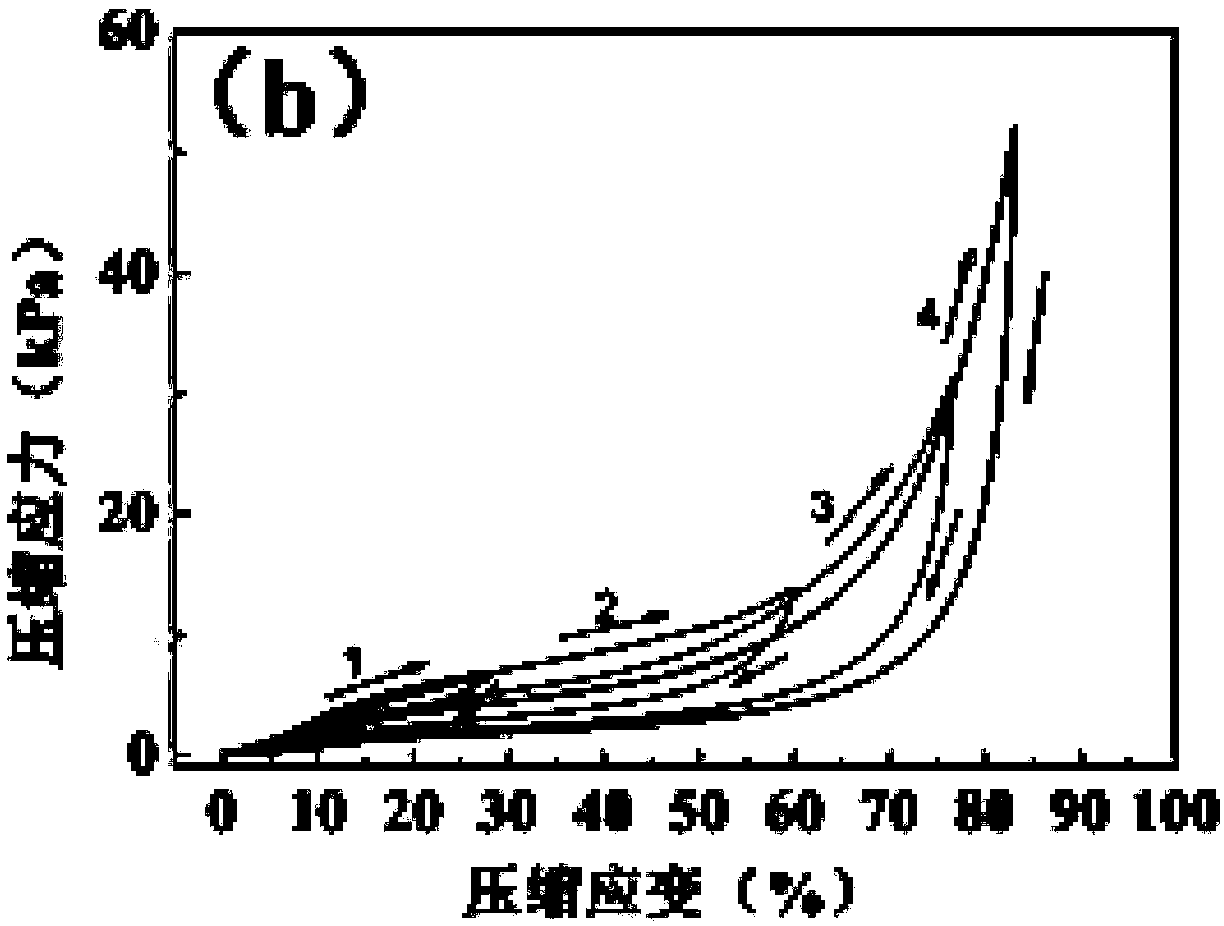

[0178] The hollow spherical carbon airgel graphene obtained by the method accounts for 80%, and the amorphous carbon accounts for 20%. The atomic percentage of oxygen element is 20%, and it is a slightly reduced carbon airgel. All have omnidirectional compressible superelasticity, and the recoverable compressive strain in different directions is 80%-99%. Strength greater than 700kPa. The density is 10mg / cm 3 , Conductivit...

specific Embodiment 2

[0180] Step (a) disperse 5 parts by mass of graphene oxide into 500 parts by mass of water to form graphene oxide and additive dispersion.

[0181] Step (b) injecting the graphene oxide dispersion liquid into a cuboid mold for supercritical drying to obtain a cuboid graphene oxide airgel, the proportion of additives is 0%, and the proportion of graphene oxide is 100%.

[0182] Step (c) heat-treating the rectangular parallelepiped graphene oxide airgel at 700° C. for 4 hours under the protection of nitrogen atmosphere to obtain the rectangular parallelepiped carbon airgel.

[0183] The carbon airgel graphene obtained by the method accounts for 100% and does not contain amorphous carbon. The atomic percentage of oxygen element is 30%, and it is a slightly reduced carbon airgel. It does not have omnidirectional compressible superelasticity, and the recoverable strain is 0%. It has recoverable compressibility, and can recover 50% of its original length when the pressure is remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com