Catalyst for preparing normal propyl alcohol through hydrogenolysis of glycerinum and preparation and using method thereof

A glycerin hydrogenolysis and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low selectivity and low conversion rate of propanol, etc. Achieve the effects of overcoming easy inactivation, good coordination, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

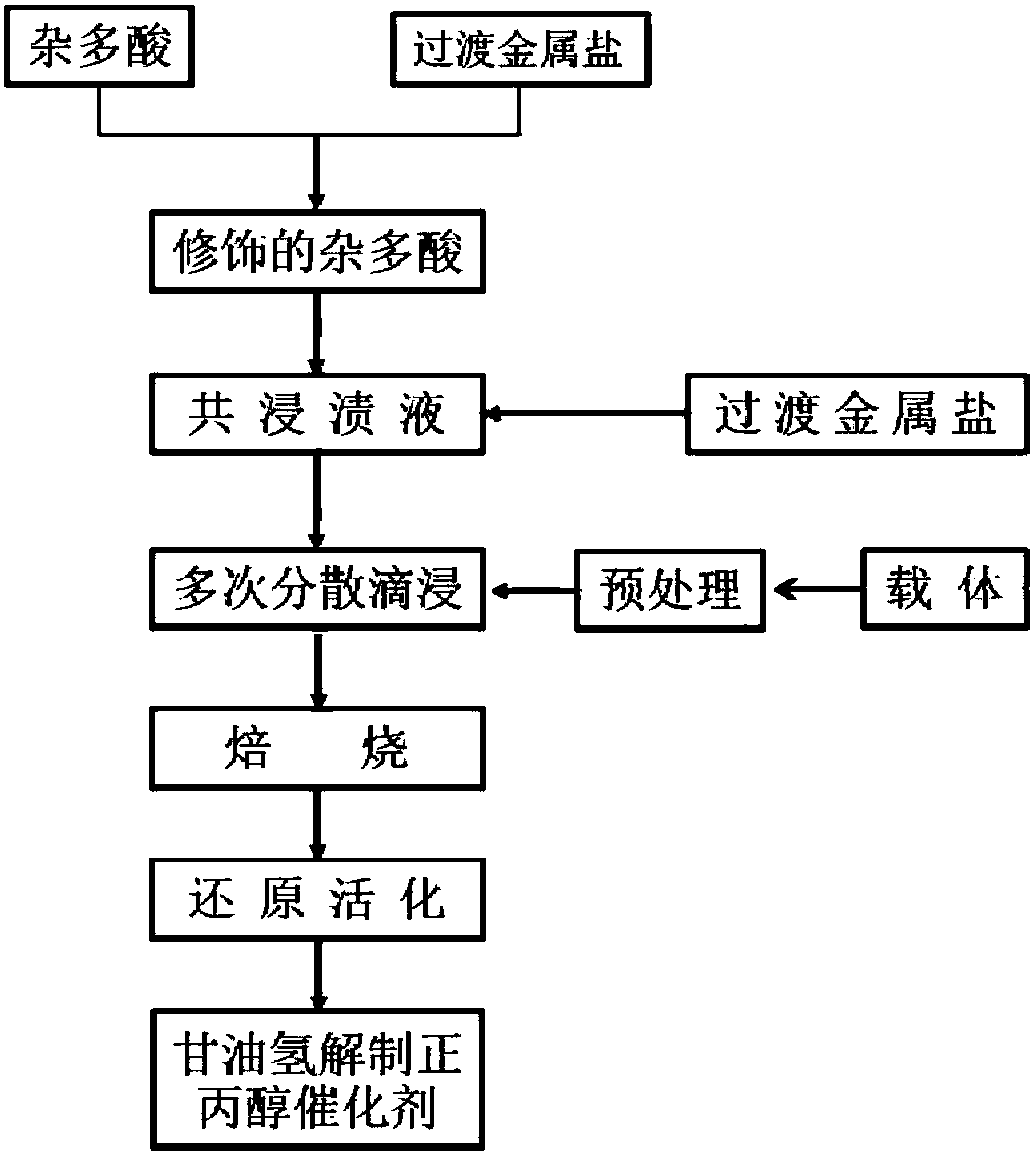

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Dissolve 0.1mol silicotungstic acid and 0.03mol nickel nitrate in 200ml acetic acid solution, adjust the pH value of the solution to 3.5, react in a constant temperature water bath at 80°C for 0.5 hours, let stand at room temperature for 8 hours, and then evaporate to dryness in an oil bath. Dry overnight at 50°C in a vacuum oven to obtain H 4 ikB 12 powder. Al will be used as carrier 2 o 3 Soak in propanol for 2 hours, filter, and dry in an oven at 110°C for 2 hours to obtain the pretreated Al 2 o 3 carrier. Then the aforementioned heteropolyacid H of 3g 4 ikB 12 Dissolve 4.95g of nickel nitrate in 20ml of distilled water to make a co-impregnation solution, divide it into 5 equal parts, and spray it on 20g of pretreated Al 2 o 3 On the carrier, stir fully after each spraying, and then dry the carrier in a vacuum drying oven at 110°C for 30 minutes, and the impregnating solution is fully loaded. The impregnated catalyst was calcined in a muffle furn...

Embodiment 2

[0021] Example 2: Dissolve 0.1mol of phosphotungstic acid and 0.03mol of zinc nitrate in 200ml of acetic acid solution, adjust the pH value of the solution to 5.5, react in a constant temperature water bath at 80°C for 1 hour, let stand at room temperature for 10 hours, and then evaporate to dryness in an oil bath. Dry overnight at 50°C in a vacuum oven to obtain H 3 wxya 12 powder. TiO will be used as a carrier 2 Soak in propanol for 2 hours, filter, and dry in an oven at 110°C for 3 hours to obtain the pretreated Al 2 o 3 carrier. Then the aforementioned heteropolyacid H of 5.67g was prepared 3 NiPW 12 Dissolve 4.55g of zinc nitrate in 20ml of distilled water to make a co-impregnation solution, divide it into 5 equal parts, and spray it on 20g of pretreated Al2 o 3 On the carrier, stir fully after each spraying, and then dry the carrier in a vacuum drying oven at 110°C for 30 minutes, and the impregnating solution is fully loaded. The impregnated catalyst was calcine...

Embodiment 3

[0023] Example 3: Dissolve 0.1mol silicotungstic acid and 0.03mol zinc nitrate in 200ml acetic acid solution, adopt a method similar to Example 1, use SiO 2 As a carrier, prepare Zn / H 4 wxya 12 / SiO 2 catalyst. The prepared Zn / H 4 wxya 12 / SiO 2 Catalyst 2g, distilled water 70g, glycerin 30g, put into the autoclave, add initial pressure (hydrogen) to 6MPa, stir 700 rpm, heat up to 450 ℃, react for 8 hours, the conversion rate of glycerin is 87.8%, and the n-propyl Alcohol selectivity was 90.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com