PH sensitive corn protein-based compound membrane and preparation method thereof

A zein and sensitive technology, which is applied in the field of composite materials and drug carrier materials, can solve the problems of complex preparation process of drug composite membranes and lack of stimuli responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

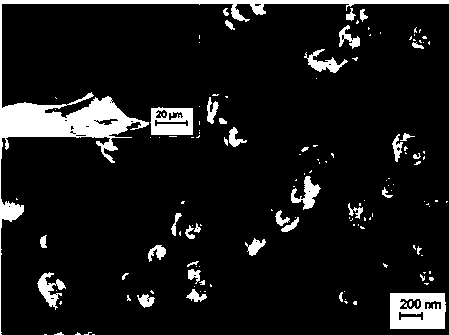

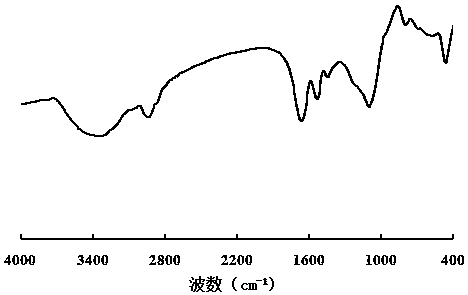

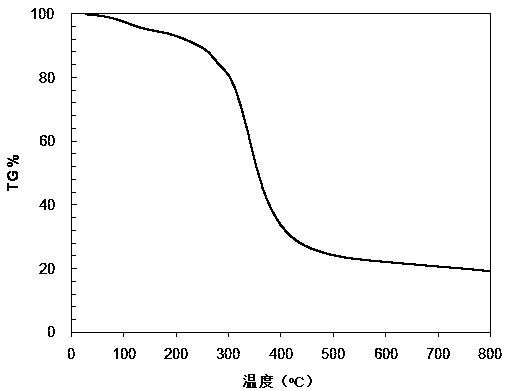

[0029] Weigh 2 g of zein into a round bottom flask, add 12 mL of aqueous methanol (70% alcohol concentration), and stir at room temperature for 9 min to obtain a uniform zein dispersion. Weigh 0.2 g nano-SiO 2 , added to the zein dispersion, and ultrasonically dispersed for 6 minutes. After adding 0.8mL glycerin to it, raise the temperature to 60°C, and after magnetic stirring for 2 hours, apply the film-forming solution on the tinplate sheet, let it stand for cooling for 15 minutes, dry at 50°C for 1 hour, and peel off the film. The pH-sensitive zein-based composite membrane was obtained by storing in the medium for 18 h.

[0030] Take 0.5 g of dried zein-based composite film, dissolve it in 7 mL of 70% ethanol aqueous solution, add 1.5 mg of the drug molecule riboflavin, raise the temperature to 70 °C, stir for 2 h with magnetic force, and coat the film-forming solution separately. On the cleaned tinplate (12cm×5cm), let it stand for cooling for 10 minutes, bake in a const...

Embodiment 2

[0032] Weigh 2.5 g of zein into a round bottom flask, add 20 mL of 70% ethanol aqueous solution, and stir at room temperature for 15 min to obtain a uniform zein dispersion. Weigh 0.25g nano-SiO 2 , added to the above zein dispersion, and ultrasonically dispersed for 10 min. After adding 0.2 mL of glycerin and 0.7 g of polyethylene glycol to the reaction liquid, the temperature was raised to 65°C, and after magnetic stirring for 3 h, the film-forming liquid was coated on a tinplate sheet, left to cool for 20 min, and dried at a constant temperature of 65°C for 1.5 h, peeling off, and storing the film in a humidity-controlled box for 20 hours to obtain a pH-sensitive zein-based composite film.

[0033] Take 0.5 g of dried zein-based composite film, dissolve it in 7 mL of 70% ethanol aqueous solution, add 3 mg of the drug molecule riboflavin, raise the temperature to 70 °C, stir magnetically for 2 h, and coat the film-forming solution separately. On the cleaned tinplate (12cm×...

Embodiment 3

[0035] Weigh 3 g of zein into a round bottom flask, add 15 mL of ethanol aqueous solution, and stir at room temperature for 20 min to obtain a uniform zein dispersion. Weigh 0.4 g nano-SiO 2 , added to the above zein dispersion, and ultrasonically dispersed for 12 minutes. After adding 1.4 mL of glycerin to it, the temperature was raised to 70°C, and after magnetic stirring for 3.5 h, the film-forming solution was coated on a tinplate sheet, left to cool for 26 min, dried at a constant temperature of 60°C for 3 h, peeled off, and the film was placed in a humidity control box. Stored in medium for 28 hours, a pH-sensitive zein-based composite film was obtained.

[0036] Take 0.5 g of dried zein-based composite film, dissolve it in 7 mL of 70% ethanol aqueous solution, add 5 mg of the drug molecule riboflavin, raise the temperature to 70 °C, stir for 2 h with magnetic force, and coat the film-forming solution separately. On the cleaned tinplate (12cm×5cm), let it stand for cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com