Beam loss detector device for ion accelerator

A technology of ion accelerators and detectors, applied in the direction of measuring devices, radiation measurement, instruments, etc., can solve the problems of long time, drop of measured value, easy to be damaged, etc., and achieve the effect of good measurement accuracy and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further detailed in conjunction with the best examples shown in the drawings:

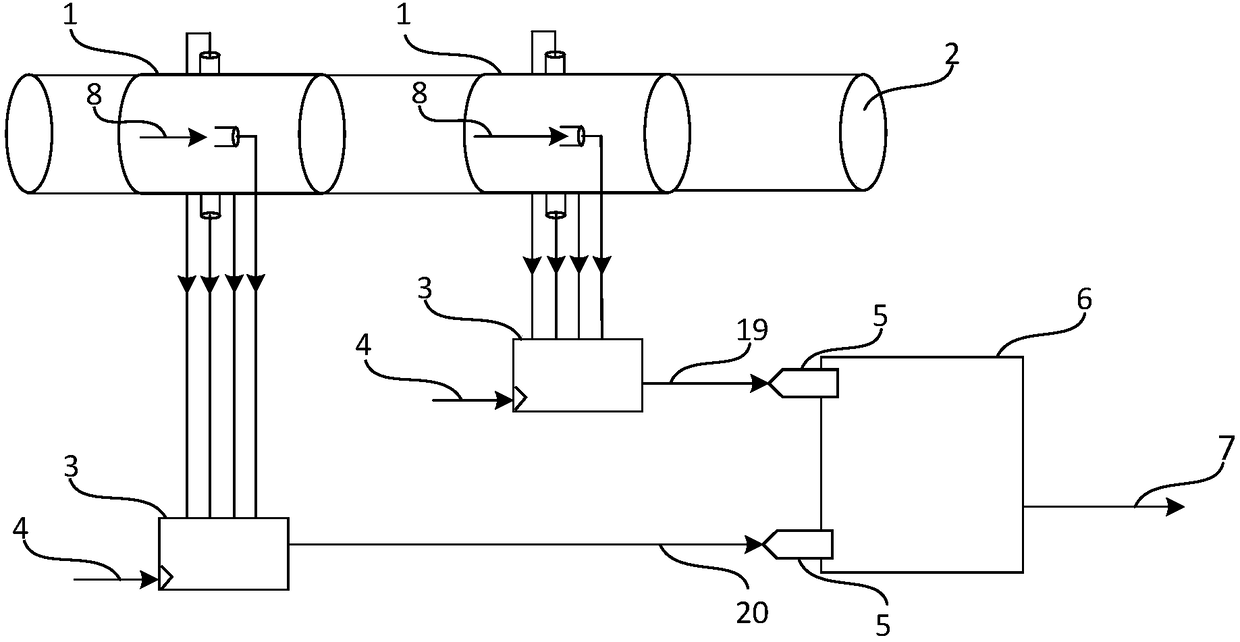

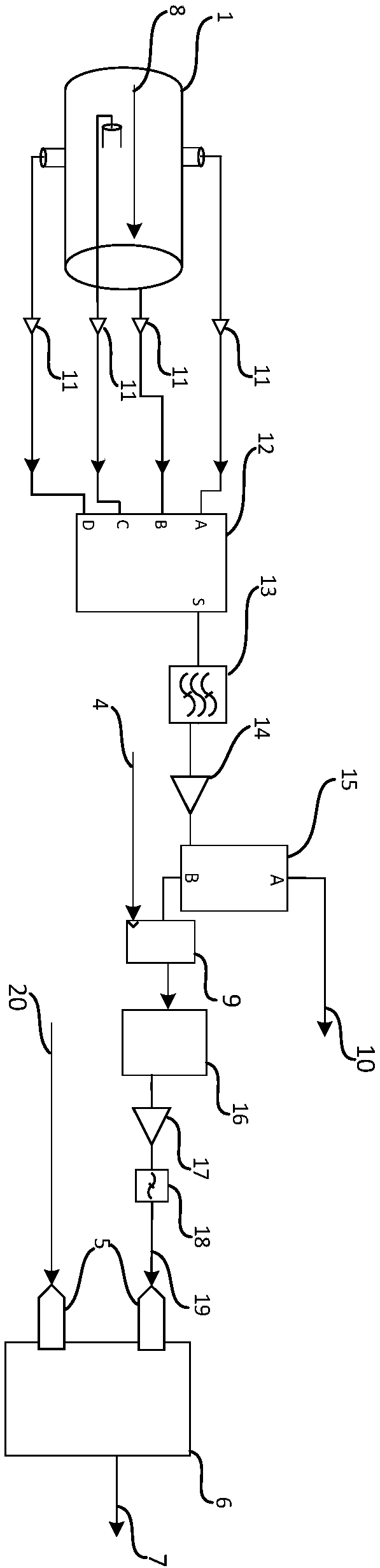

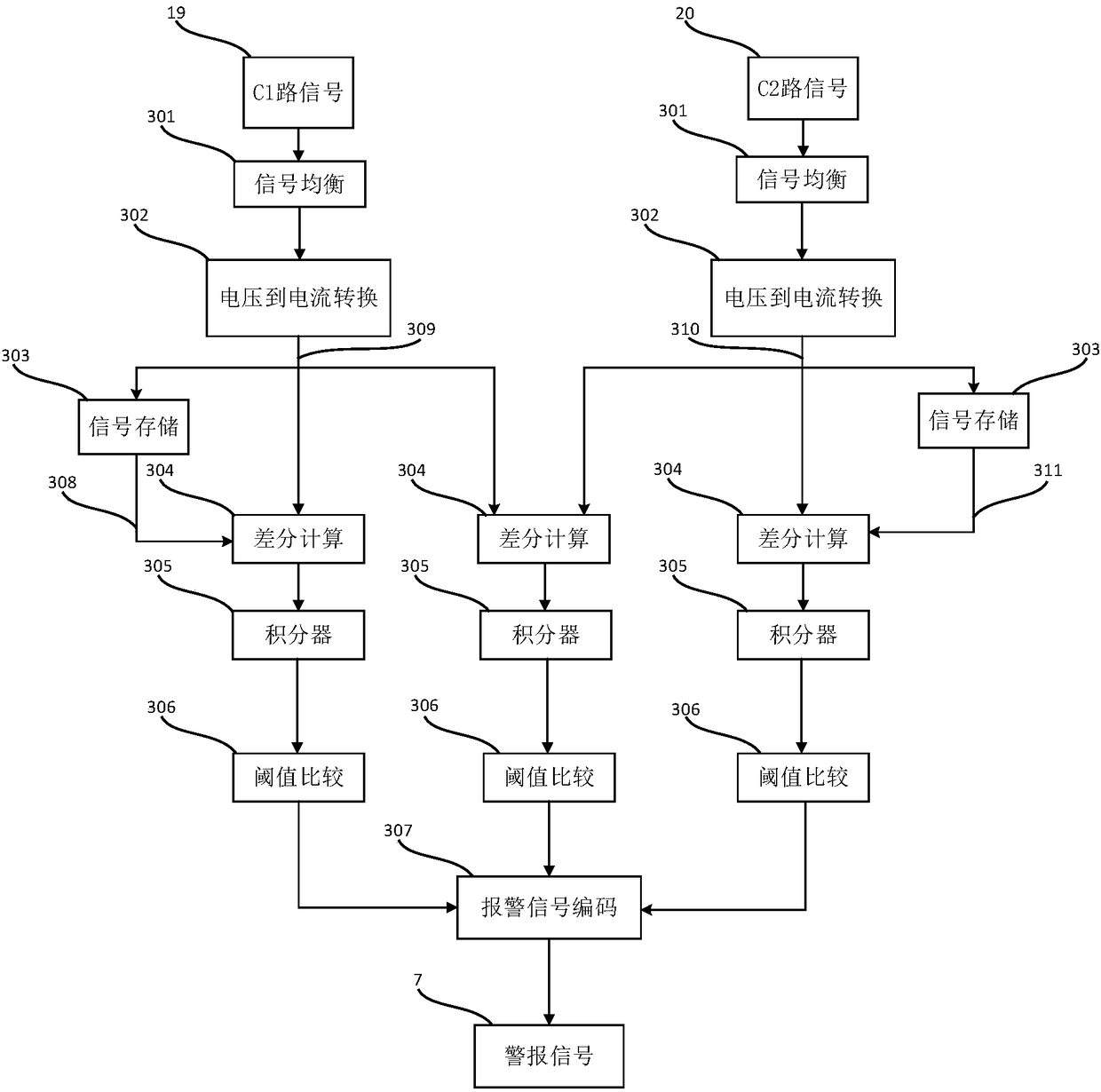

[0018] Such as Figure 1 to 3 As shown, the described beam loss detector device for an ion accelerator is characterized by comprising two beam position probes 1, which are arranged at intervals on the cluster vacuum pipe 2 and are located upstream and downstream, respectively. The stream position probe 1 is respectively connected to the respective front-end processing circuit 3 and driven by the trigger signal 4. The front-end processing circuit 3 is connected to the high-speed sampling digital circuit board 6 through the analog-to-digital conversion circuit 5, and there are a pair of beam position probes at upstream and downstream. The particle bunch 8 obtains the synchronization signal and generates the digital signal to be processed through the high-speed sampling digital circuit board 6. When the difference between the signal and its historical data exceeds a certain thresh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com