Washing machine upper frame mold

A washing machine and mold technology, which is applied in the field of the upper frame mold of the washing machine, can solve the problems of long molding cooling time, low product qualification rate, and high molding pressure, and achieve the effect of reducing the heating process of the hair dryer, satisfactory appearance, and good full pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

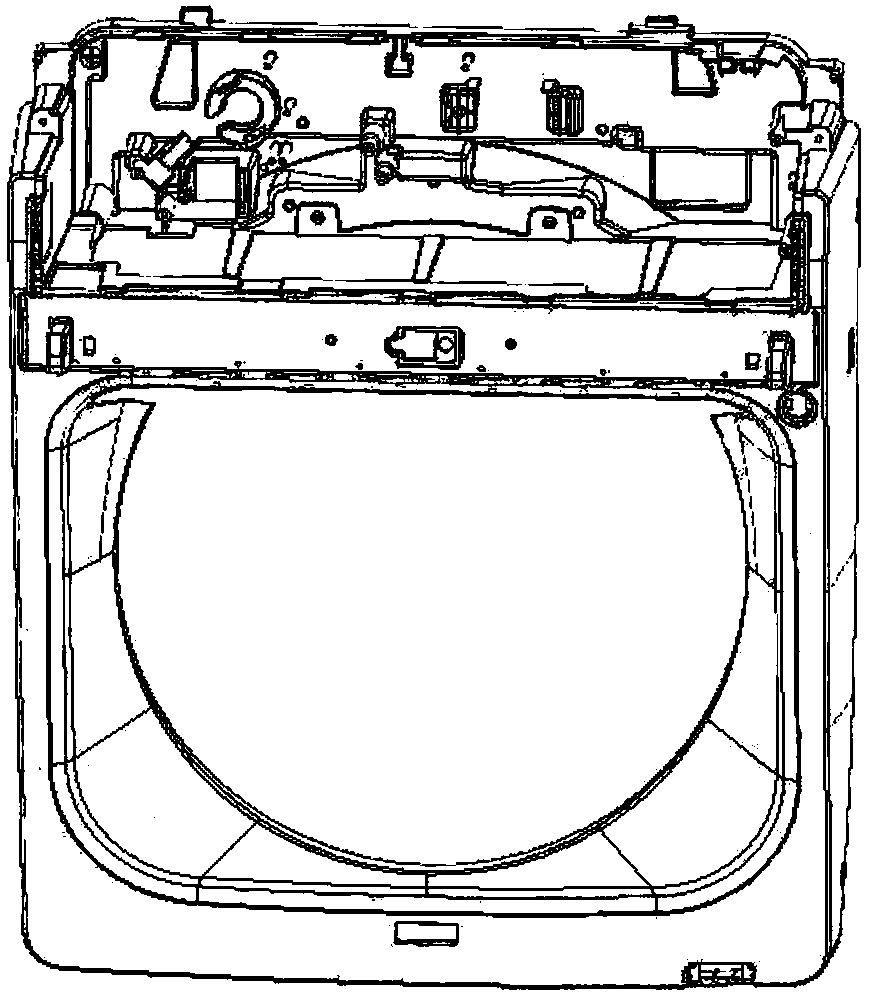

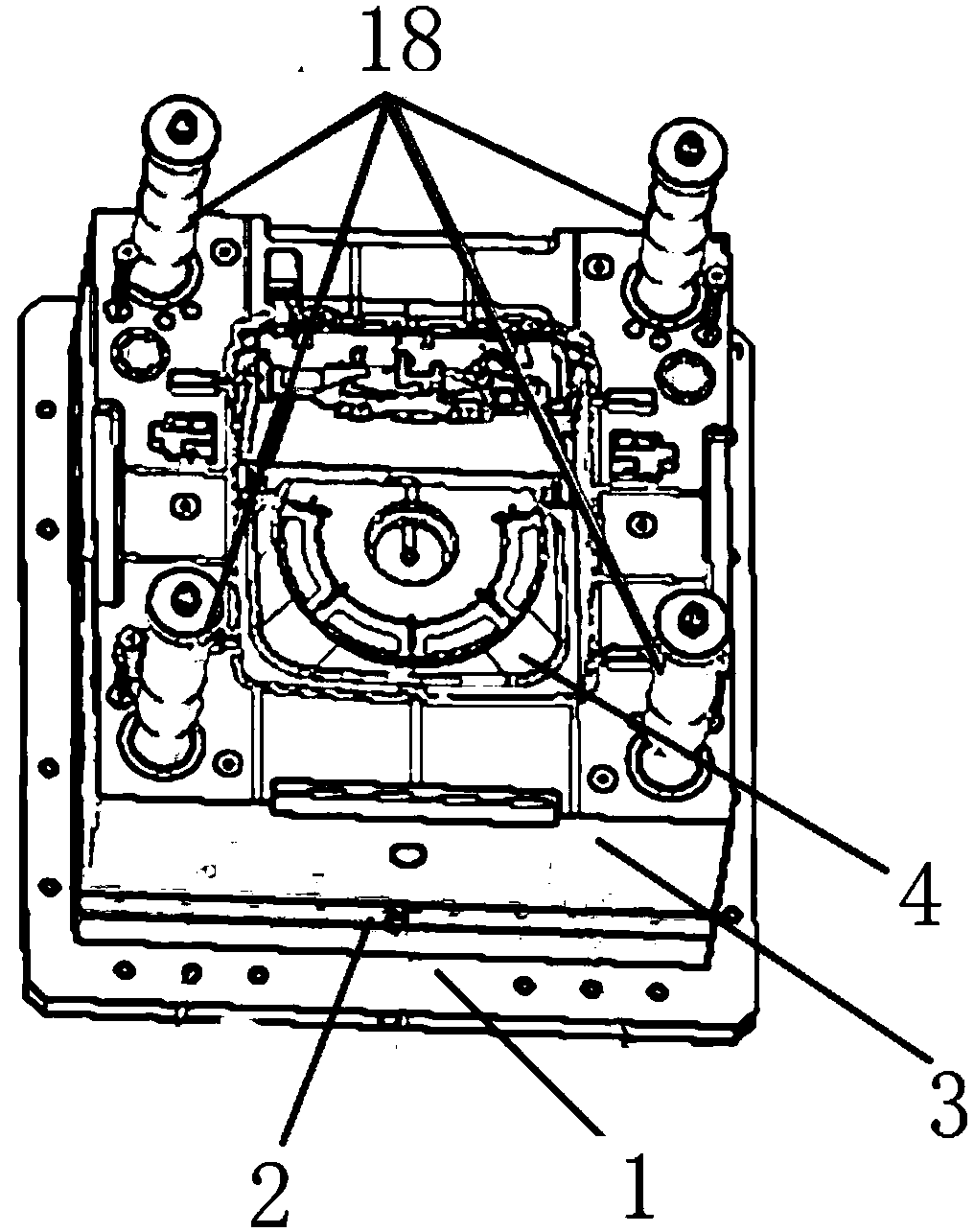

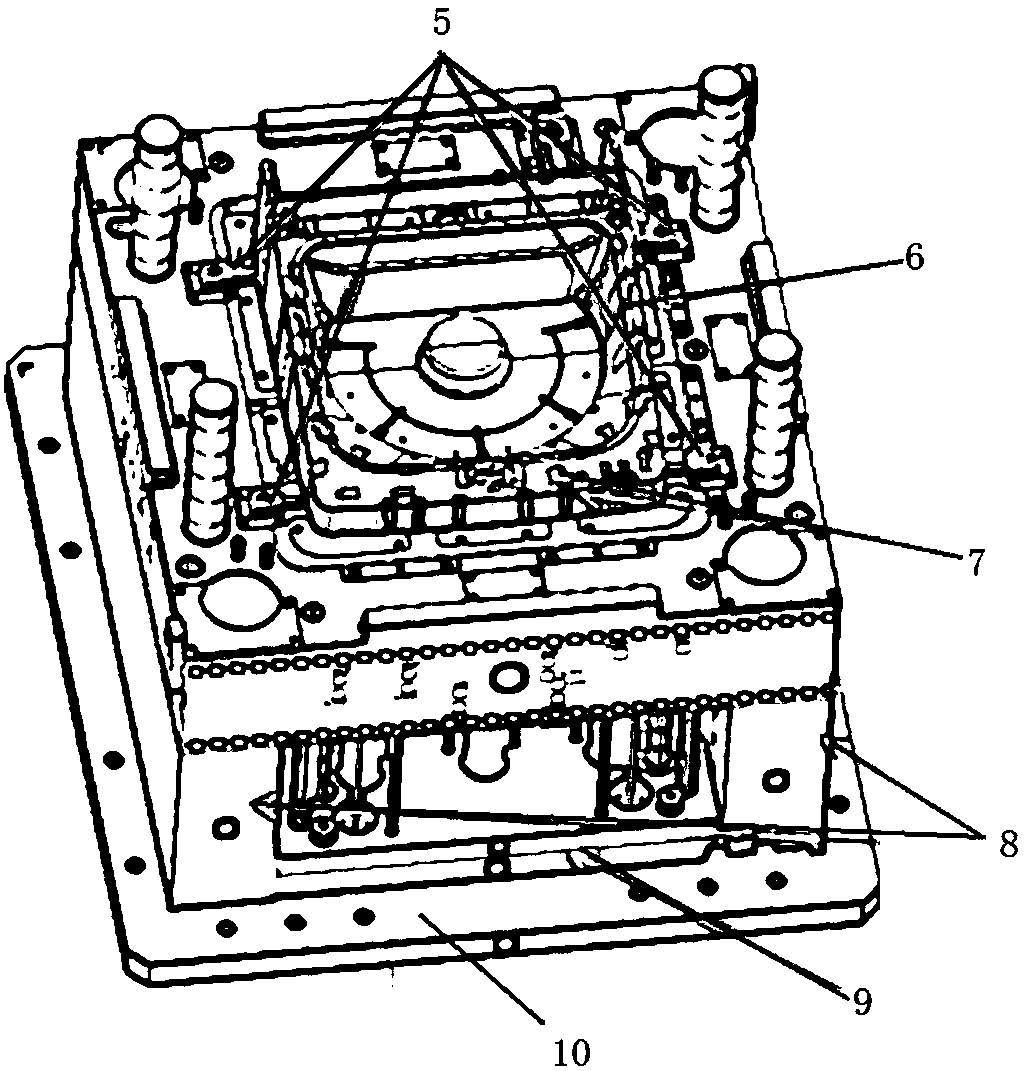

[0024] A washing machine upper frame mold, such as Figure 2-6 As shown, it is used for the upper frame of the washing machine (for parts, see figure 1 ), including an upper mold and a lower mold, the upper mold includes an upper fixed plate 1, a stripping plate 2 and an A plate 3 arranged sequentially from top to bottom, the A plate 3 is inlaid with an upper mold core 4, and the lower mold includes a The lower fixed plate 10, the square iron 8 and the B plate are arranged in sequence from bottom to top. The lower mold core 6 is inlaid on the B plate. There is also a thimble plate 9 between the lower fixed plate 10 and the B plate. There are a plurality of workpiece thimbles 16, and the end of the workpiece thimble 16 is provided with a jacking block 7, and between the jacking block 7 and the workpiece thimble 16, a Uli rubber pad 17 is arranged. There are two square irons 8, and the thimble plate 9 is provided between the two square irons 8. The thimble plate 9 is made up o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com