Method and technological system for achieving high-efficiency removal and resource utilization of NOx in ultralow temperature smoke

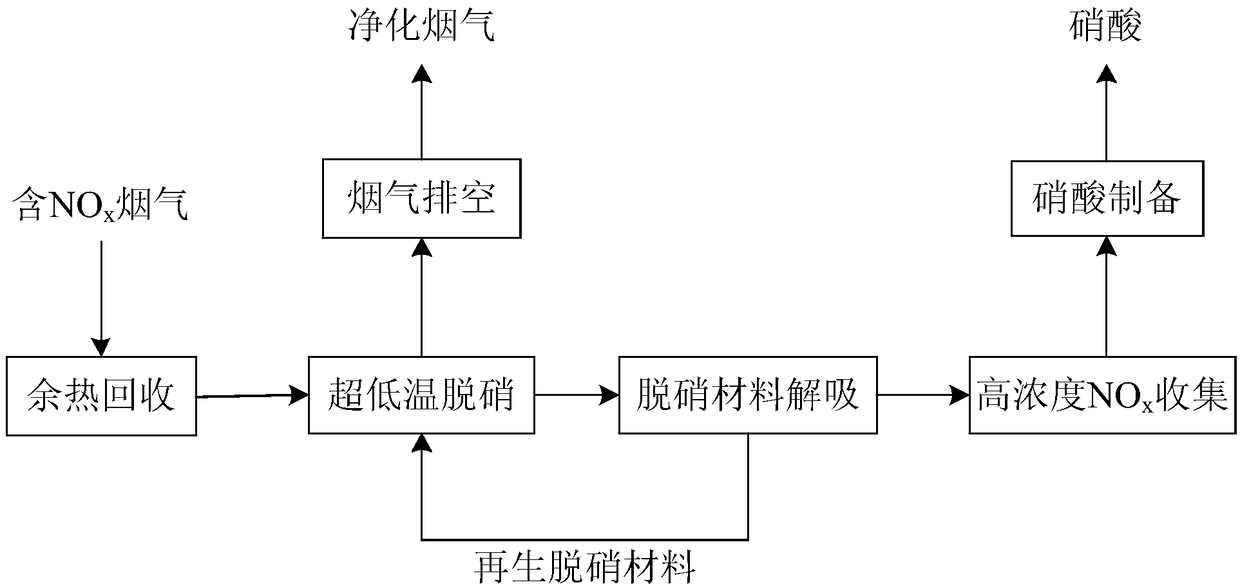

A resource-based, ultra-low temperature technology, applied in the field of air pollutant control, can solve the problems of poor operating conditions and the lack of general applicability of denitrification technology, achieve operating cost savings, obvious advancement and economy, and widen the denitration temperature window. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

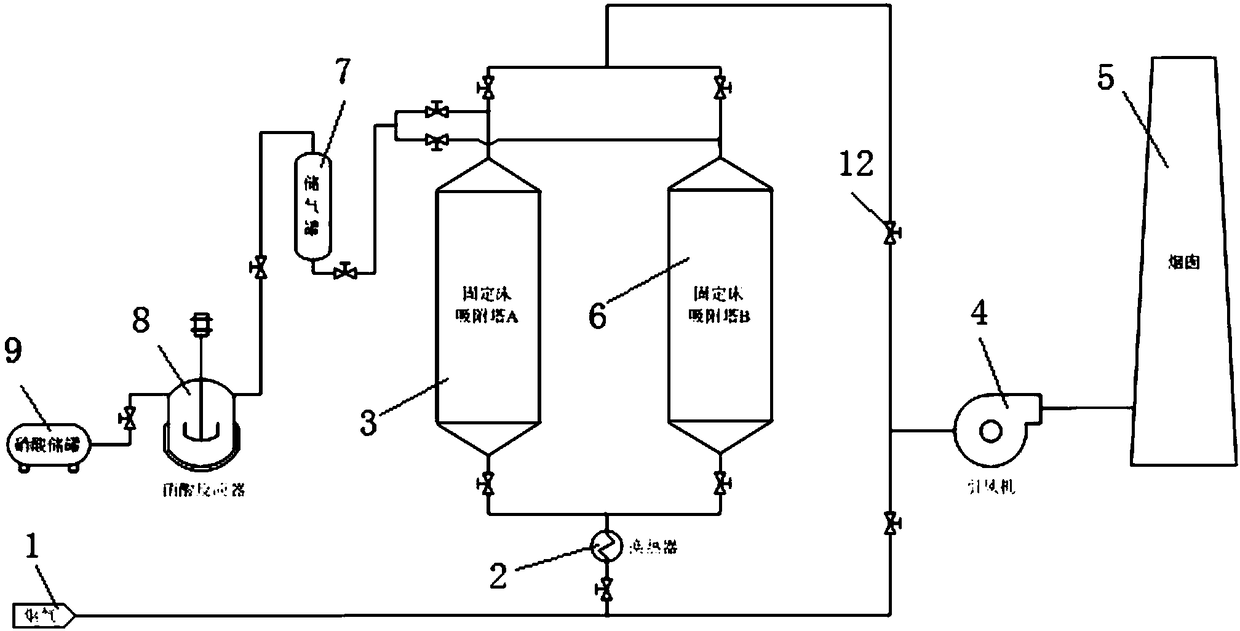

Embodiment 1

[0068] The flue gas of the power plant is treated. After the flue gas is recovered by waste heat, the exhaust gas temperature is 55°C, and the NO x Contains 600mg / m 3 . The flue gas is denitrated by the fixed bed adsorption process, the denitrification temperature is set at 55°C, and the regeneration temperature is set at 135°C. After treatment, the NO in the flue gas x content down to 43mg / m 3 , meeting the special emission limit requirements in the "Emission Standards of Air Pollutants for Thermal Power Plants" (GB13223-2011). The high concentration of NO obtained during the regeneration of denitrification materials x into the nitric acid preparation system, with O 2 is an oxidizing agent, H 2 O is a solvent, the reaction temperature is set at 25° C., the reaction time is set at 1 min, and the reaction pressure is set at 0.02 MPa. After chemical reaction and concentration, a nitric acid product with a mass percentage of not less than 60% is obtained.

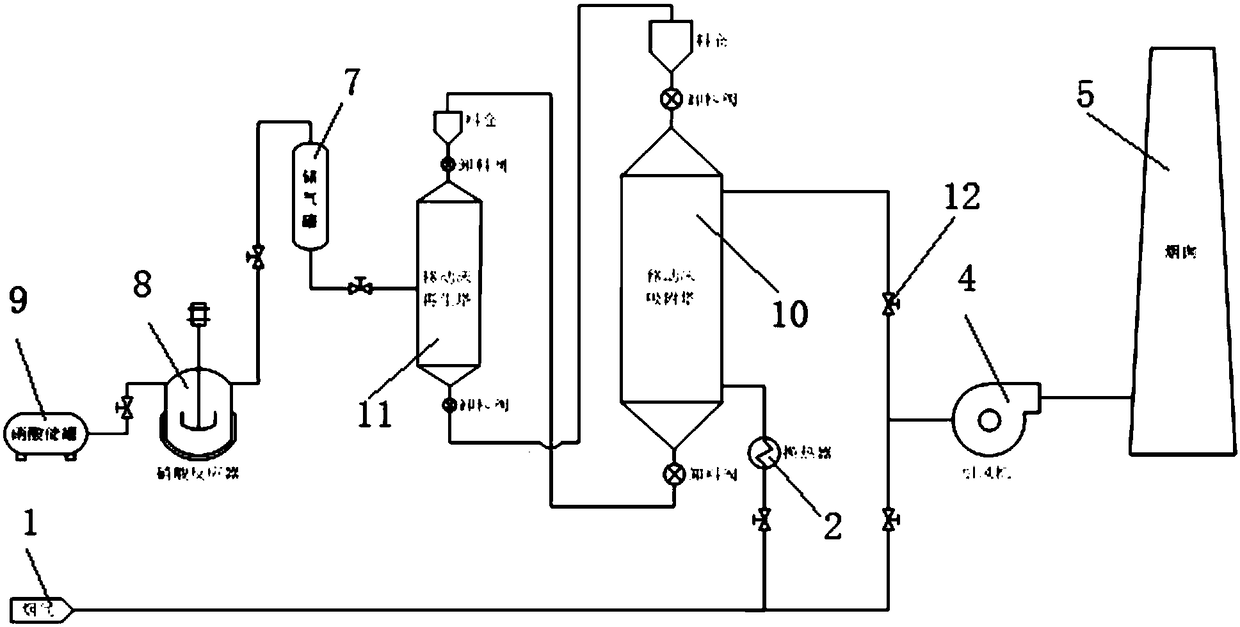

Embodiment 2

[0070] The flue gas of the power plant is treated. After the flue gas is recovered by waste heat, the exhaust gas temperature is 55°C, and the NO x Contains 600mg / m 3 . The moving bed adsorption process is used to denitrify the flue gas. The denitrification temperature is set at 55°C and the regeneration temperature is set at 135°C. After treatment, the NO in the flue gas x content down to 48mg / m 3 , meeting the special emission limit requirements in the "Emission Standards of Air Pollutants for Thermal Power Plants" (GB13223-2011). The high concentration of NO obtained during the regeneration of denitrification materials x into the nitric acid preparation system, with O 2 is an oxidizing agent, H 2 O is a solvent, the reaction temperature is set at 25° C., the reaction time is set at 1 min, and the reaction pressure is set at 0.02 MPa. After chemical reaction and concentration, a nitric acid product with a mass percentage of not less than 60% is obtained.

Embodiment 3

[0072] The coking flue gas is treated. After the flue gas is recovered by waste heat, the exhaust gas temperature is 25°C, and the NO x The content is 1500mg / m 3 . The flue gas is denitrated by fixed bed adsorption process, the denitrification temperature is set at 25°C, and the regeneration temperature is set at 105°C. After treatment, the NO in the flue gas x content down to 120mg / m 3 , to meet the requirements of the special emission limits in the "Emission Standards of Pollutants for the Coking Chemical Industry" (GB 16171-2012). Denitrification High concentration of NO obtained during material regeneration x Into the nitric acid preparation system, with air as the oxidant, H 2 o 2 As a solvent, the reaction temperature is set at 55°C, the reaction time is set at 15min, and the reaction pressure is set at 0.9MPa. After chemical reaction and concentration, a nitric acid product with a mass percentage of not less than 60% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com