Graphene patch for treating hyperplasia of mammary glands and preparation method thereof

A production method, the technology of ene mammary glands, applied in the direction of phototherapy, medical formula, medical raw materials derived from algae, etc., can solve the problems of insufficient absorption of the affected area, low drug utilization rate, slow healing effect, etc., to improve microcirculation , Improve the effect of tissue support and improve the cure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation approach Embodiment 1

[0034] formula:

[0035] 7 parts by weight of lychee core, 3 parts by weight of dodder seed, 3 parts by weight of japonica japonica, 6 parts by weight of seaweed, 6 parts by weight of dogwood, 0.3 part by weight of roasted licorice and 0.3 part by weight of ginger pinellia.

[0036] Preparation Process:

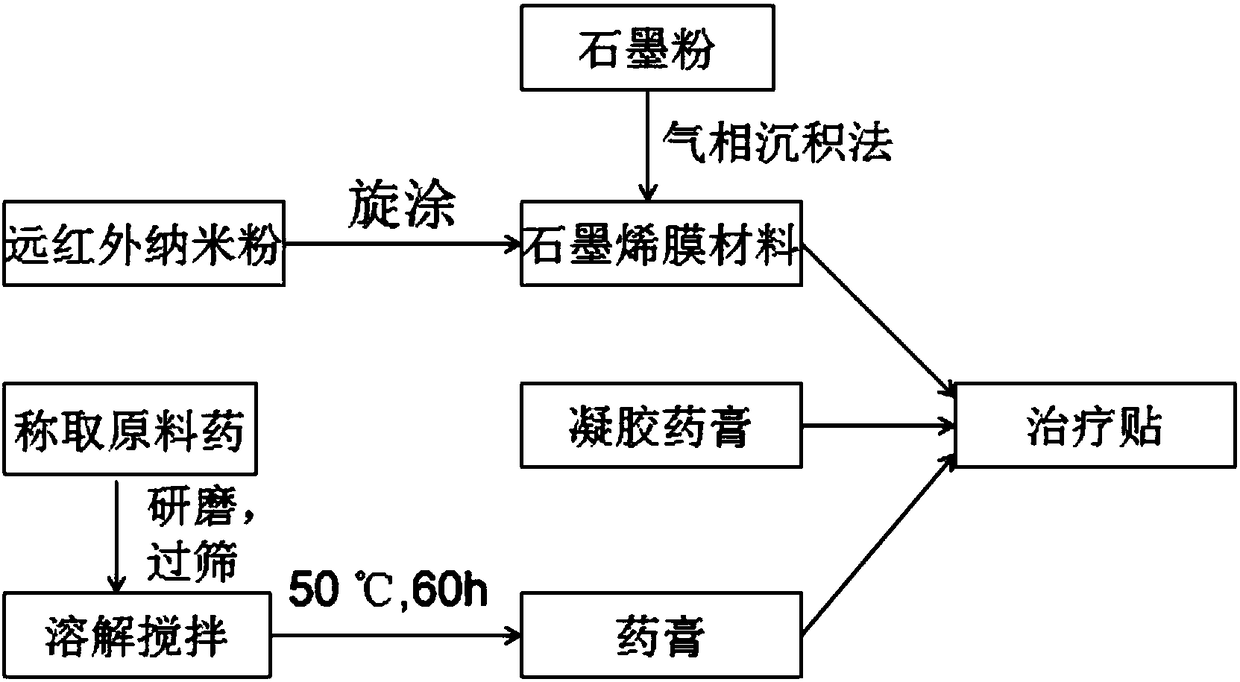

[0037] S1, the graphene film material is evenly deposited on the surface of the backing layer by vapor deposition method, and extruded to form a film;

[0038] S2, take 4 parts by weight of far-infrared nano-powder according to the formula, and evenly spin-coat it on the surface of the graphene film layer in S1;

[0039] S3, weighing the following raw materials according to the formula quantity: 7 parts by weight of litchi core, 3 parts by weight of dodder seed, 3 parts by weight of Jade leaf golden flower, 6 parts by weight of seaweed, 6 parts by weight of Cornus officinalis, 0.3 parts by weight of roasted licorice and 0.3 parts by weight of Pinellia ginger;

[0040] S4, a...

preparation approach Embodiment 2

[0044] formula:

[0045] 5 parts by weight of lychee seed, 2 parts by weight of dodder seed, 2 parts by weight of Jade leaf golden flower, 3 parts by weight of seaweed, 3 parts by weight of dogwood, 0.2 part by weight of roasted licorice and 0.2 part by weight of ginger pinellia.

[0046] Preparation Process:

[0047] S1, the graphene film material is evenly deposited on the surface of the backing layer by vapor deposition method, and extruded to form a film;

[0048] S2, take 3 parts by weight of far-infrared nano-powder according to the formula, and evenly spin-coat it on the surface of the graphene film layer in S1;

[0049] S3, weighing the following raw materials according to the formula: 5 parts by weight of lychee core, 2 parts by weight of dodder seed, 2 parts by weight of Jade leaf golden flower, 3 parts by weight of seaweed, 3 parts by weight of Cornus officinalis, 0.2 part by weight of Zhilicorice and 0.2 part by weight of Pinellia ginger;

[0050] S4, after grind...

preparation approach Embodiment 3

[0054] formula:

[0055] 10 parts by weight of lychee seed, 5 parts by weight of dodder seed, 5 parts by weight of Jade leaf golden flower, 8 parts by weight of seaweed, 8 parts by weight of dogwood, 0.5 part by weight of roasted licorice and 0.5 part by weight of ginger pinellia.

[0056] Preparation Process:

[0057] S1, the graphene film material is evenly deposited on the surface of the backing layer by vapor deposition method, and extruded to form a film;

[0058] S2, take 5 parts by weight of far-infrared nano-powder according to the formula, and evenly spin-coat it on the surface of the graphene film layer in S1;

[0059] S3, weighing the following raw materials according to the formula: 10 parts by weight of lychee seed, 5 parts by weight of dodder seed, 5 parts by weight of Jade leaf golden flower, 8 parts by weight of seaweed, 8 parts by weight of Cornus officinalis, 0.5 part by weight of roasted licorice and 0.5 part by weight of Pinellia ginger;

[0060] S4, afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com