Liquid crystal alignment composition, method for preparing liquid crystal alignment film using same, and liquid crystal alignment film using same

一种液晶取向、液晶取向剂的技术,应用在液晶材料、化学仪器和方法、仪器等方向,能够解决难以确保生产率、大量能量、聚酰亚胺难以表现出高电压保持率等问题,达到降低光照射能量、高电压保持率、增强取向特性和稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

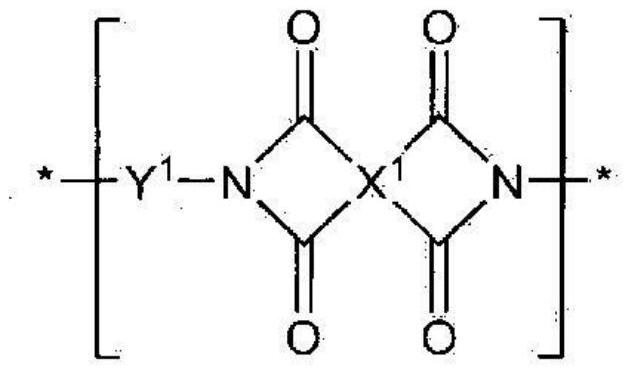

[0137] Preparation Example 1: Synthesis of Diamine DA-1

[0138] Diamine DA-1 was synthesized according to the following reaction.

[0139]

[0140] Specifically, CBDA (cyclobutane-1,2,3,4-tetracarboxylic dianhydride) and 4-nitroaniline were dissolved in DMF (dimethylformamide) to prepare a mixture. Then, the mixture was reacted at about 80° C. for about 12 hours to prepare amic acid. Subsequently, amic acid was dissolved in DMF, and acetic anhydride and sodium acetate were added thereto to prepare a mixture. Then, the amic acid contained in the mixture was imidized at about 90° C. for about 4 hours. The imide thus obtained was dissolved in DMAc (dimethylacetamide), and then palladium on carbon (Pd—C) was added thereto to prepare a mixture. The mixture was reduced at 45° C. for 20 minutes under a hydrogen pressure of 6 bar to prepare diamine DA-1.

preparation example 2

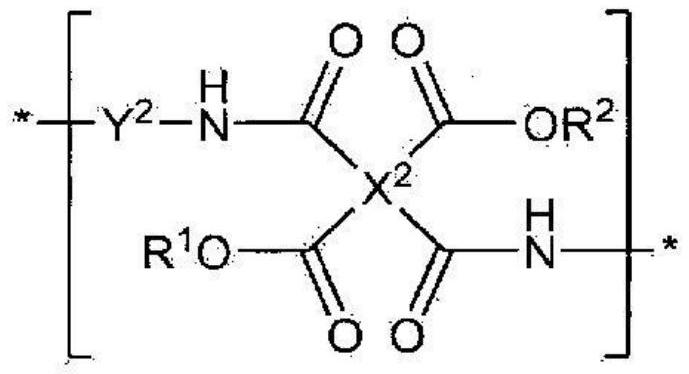

[0141] Preparation Example 2: Synthesis of Diamine DA-2

[0142]

[0143] DA-2 having the above structure was prepared in the same manner as in Preparation Example 1, except that DMCBDA (1,3-dimethylcyclobutane-1,2,3,4-tetracarboxylic dianhydride) was used Instead of CBDA (cyclobutane-1,2,3,4-tetracarboxylic dianhydride).

preparation example 3

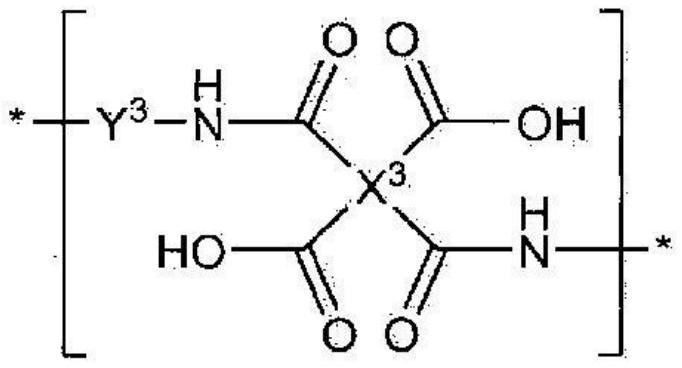

[0144] Preparation Example 3: Synthesis of Diamine DA-3

[0145] Diamine DA-3 was synthesized according to the following reaction.

[0146]

[0147] Specifically, 25 g of CBDA (cyclobutane-1,2,3,4-tetracarboxylic dianhydride) was added to 250 mL of methanol, 1 to 2 drops of hydrochloric acid were added thereto, and the mixture was heated at 75°C under reflux Heat for 5 hours. After removing the solvent under reduced pressure, 300 mL of ethyl acetate and n-hexane were added to solidify the solution. The resulting solid was collected by vacuum filtration and dried at 40 °C under reduced pressure to obtain 32 g of M1.

[0148] To 34 g of the obtained M1 was added 100 mL of toluene, and then 35 g of oxalyl chloride was added dropwise at room temperature. 2 to 3 drops of dimethylformamide (DMF) were added dropwise and the mixture was stirred at 50°C for 16 hours. After cooling to room temperature, the solvent and residual oxalyl chloride were removed under reduced pressure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com