Novel heat pipe steam boiler

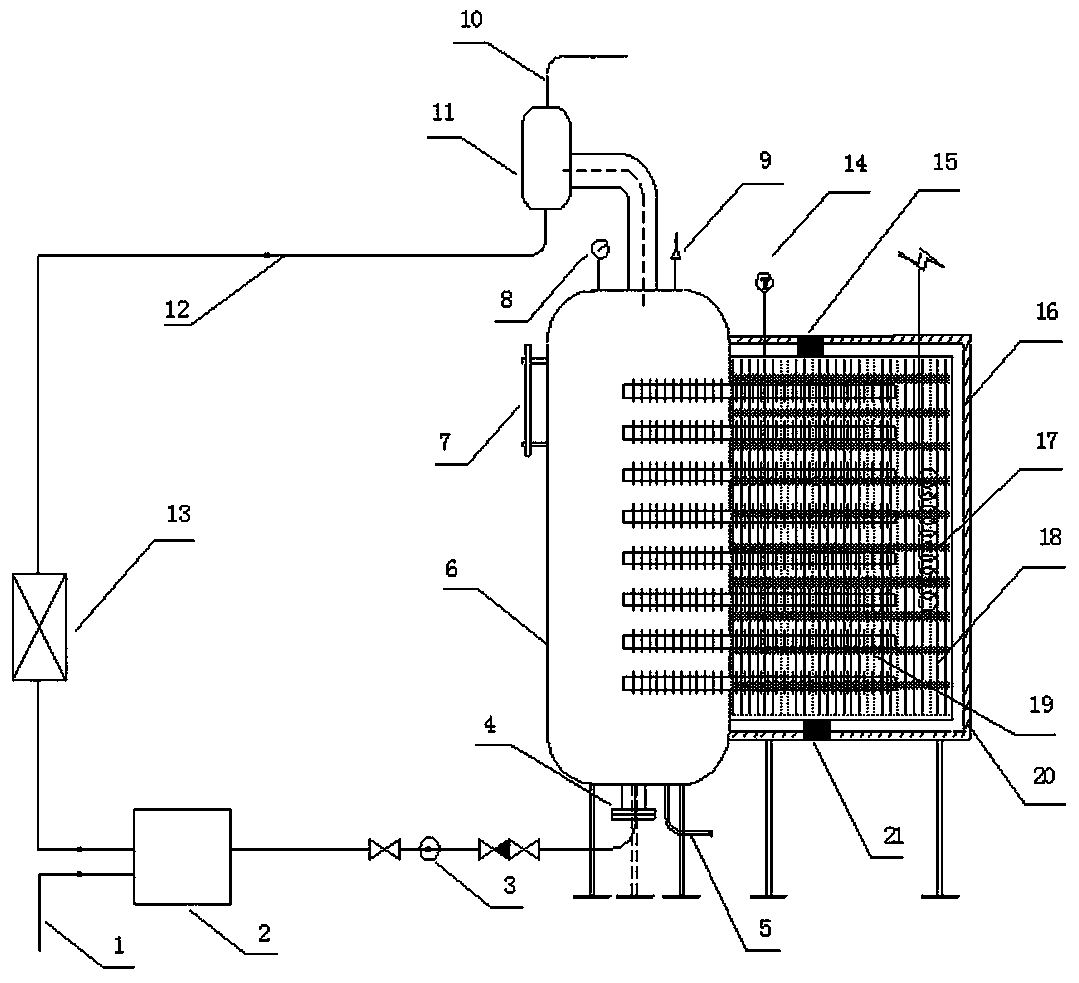

A technology for steam boilers and heat pipes, applied in the field of new heat pipe steam boilers, can solve the problems of small heat transfer coefficient, low heat storage efficiency, and inability to generate high-pressure steam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, taking a certain place in Liaoning as an example, the local valley electricity time is from 22:00 to 6:00 the next day. The molten salt heating system is started during the valley electricity time, and low-cost electricity is introduced into the electric heating device 17. The heating device 17 converts the valley electricity into heat energy and stores it through the heat storage molten salt. The outer side of the valley electricity heating and heat storage system uses ultra-fine glass wool as the outer insulation 13 to wrap the tank body 16 with the heat storage molten salt 18. Port 15 and discharge port 21 carry out supplementary replacement of thermal storage molten salt, electric heating device 17 adds thermal storage molten salt 18 to raise the temperature to about 500 degrees Celsius, and the real-time temperature in the tank body 16 can be known through the thermometer 14, and the heat pipe heat transfer group The hot end of 19 is located in the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com