Manufacturing technique of high-adding-quantity fly ash sintered hollow brick

A production process and a technology for fly ash, applied in the field of hollow bricks, can solve the problems of cumbersome, difficult, and difficult to mass-produce the binder blending process, and achieve the effects of shortening the roasting time, being easy to operate, and shortening the drying cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

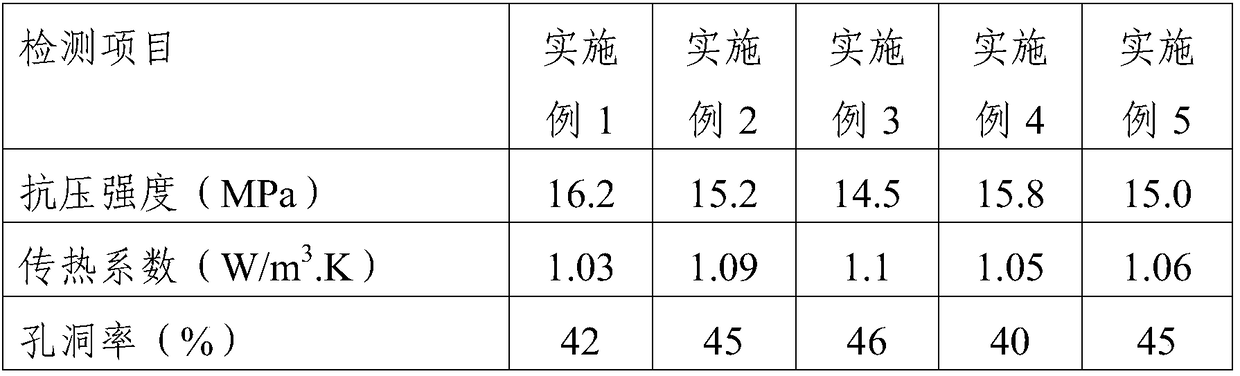

Examples

Embodiment 1

[0023] A production process for high-volume fly ash sintered hollow bricks, comprising the following steps:

[0024] (1) Sieve fly ash, kaolin powder, high-viscosity attapulgite clay powder, nepheline syenite powder, and mica powder with a 180-mesh sieve, crush and process the sieve residue, and then sieve with a 180-mesh sieve ; Then the second sieve residue is pulverized, and the slag is removed after using a 180 mesh sieve;

[0025] (2) Weigh 55 parts of fly ash, 18 parts of kaolin powder, 15 parts of high-viscosity attapulgite clay powder, 8 parts of nepheline syenite powder, and 3 parts of mica powder sieved through step (1), and add them to the mixer In the process, after stirring for 25 minutes, add 11 parts of river mud and 16 parts of water, and continue mixing for 30 minutes to obtain a mixture; send the mixture into the aging warehouse for aging for 28 hours;

[0026] The above-mentioned river mud is river bottom mud in rivers with less pollution and less garbage, ...

Embodiment 2

[0032] A production process for high-volume fly ash sintered hollow bricks, comprising the following steps:

[0033] (1) Sieve fly ash, kaolin powder, high-viscosity attapulgite clay powder, nepheline syenite powder, and mica powder with a 180-mesh sieve, crush and process the sieve residue, and then sieve with a 180-mesh sieve ;

[0034] (2) Weigh 57 parts of fly ash, 20 parts of kaolin powder, 14 parts of high-viscosity attapulgite clay powder, 7 parts of nepheline syenite powder, and 3 parts of mica powder sieved through step (1), and add them to the mixer In the process, after stirring for 30 minutes, add 10 parts of river mud and 18 parts of water, and continue mixing for 30 minutes to obtain a mixture; send the mixture into the aging warehouse for aging for 30 hours;

[0035] The above-mentioned river mud is the river bottom mud in rivers with less pollution and less garbage, and the water content of the river mud is 22%;

[0036] (3) Send the aged mixture into the box...

Embodiment 3

[0041] A production process for high-volume fly ash sintered hollow bricks, comprising the following steps:

[0042] (1) Sieve fly ash, kaolin powder, high-viscosity attapulgite clay powder, nepheline syenite powder, and mica powder with a 150-mesh sieve, crush and process the remaining material, and then sieve with a 150-mesh sieve ;

[0043] (2) Weigh 52 parts of fly ash, 12 parts of kaolin powder, 16 parts of high-viscosity attapulgite clay powder, 5 parts of nepheline syenite powder, and 5 parts of mica powder sieved through step (1), and add them to the mixer In the process, after stirring for 25 minutes, add 8 parts of river mud and 14 parts of water, and continue mixing for 35 minutes to obtain a mixture; send the mixture into the aging warehouse for aging for 26 hours;

[0044] The above-mentioned river mud is the river bottom mud in rivers with less pollution and less garbage, and the water content of the river mud is 28%;

[0045](3) Send the aged mixture into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com