A green and efficient synthesis method of copper-doped sba-15 mesoporous molecular sieve material

The technology of a mesoporous molecular sieve and a synthesis method is applied in the field of green and efficient synthesis of copper-doped SBA-15 mesoporous molecular sieve materials, which can solve the problems of difficult synthesis, short time and high efficiency, and achieve the effect of high synthesis efficiency and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Copper-doped SBA-15 mesoporous molecular sieve material preparation:

[0045] Step 1: Add 0.05gNa 2 S 2 o 8 Dissolve in 15mL of water, add 4.3g of TEOS into a quartz tube, and stir for 1 hour under the irradiation of a UV lamp of 100W until the solution is clear without stratification to obtain M solution;

[0046] Step 2: Dissolve 2g P123 in 85mL water, stir for 4 hours until completely dissolved, then add 0.25g Cu(Ac) 2 ·H 2 O is stirred to obtain N solution;

[0047] Step 3: Mix and stir the M solution and the N solution, and form a blue suspension in a water bath at 40°C for 8 minutes, then react for 8 hours, transfer the reaction product and mother liquor to polytetrafluoroethylene for crystallization at 80°C for 12 hours, and filter and wash after cooling , dried, and calcined at 550°C for 6h to obtain a light blue copper-doped SBA-15 mesoporous molecular sieve material.

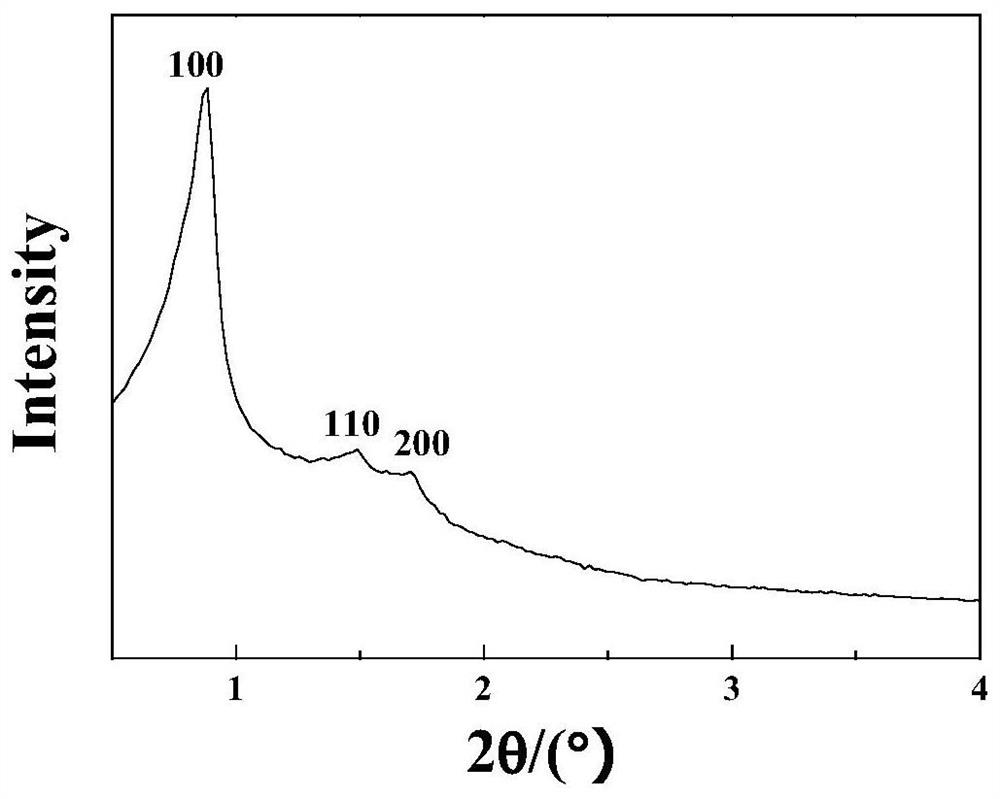

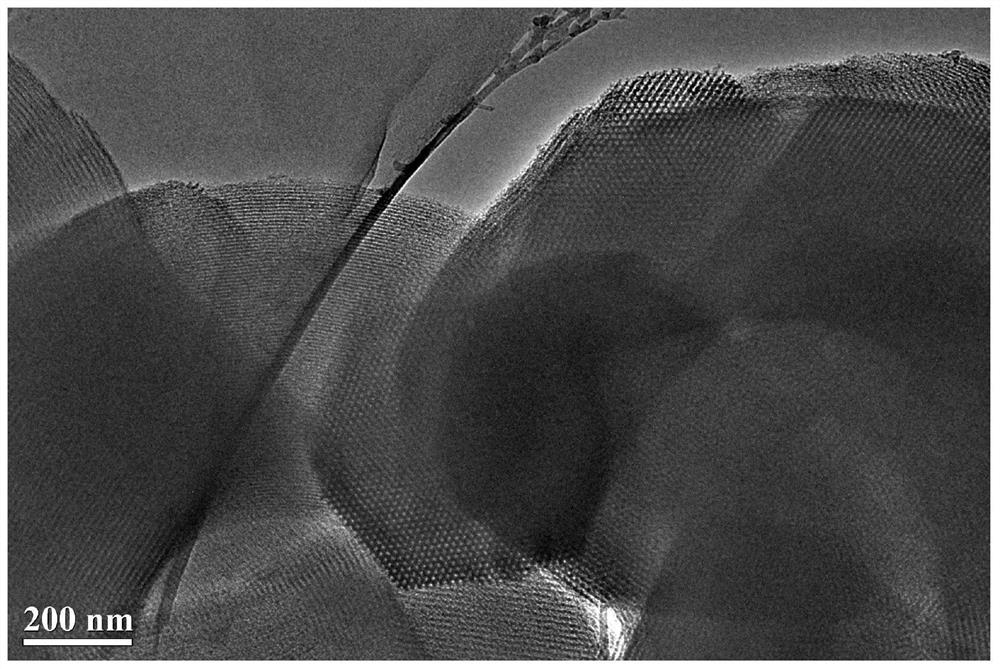

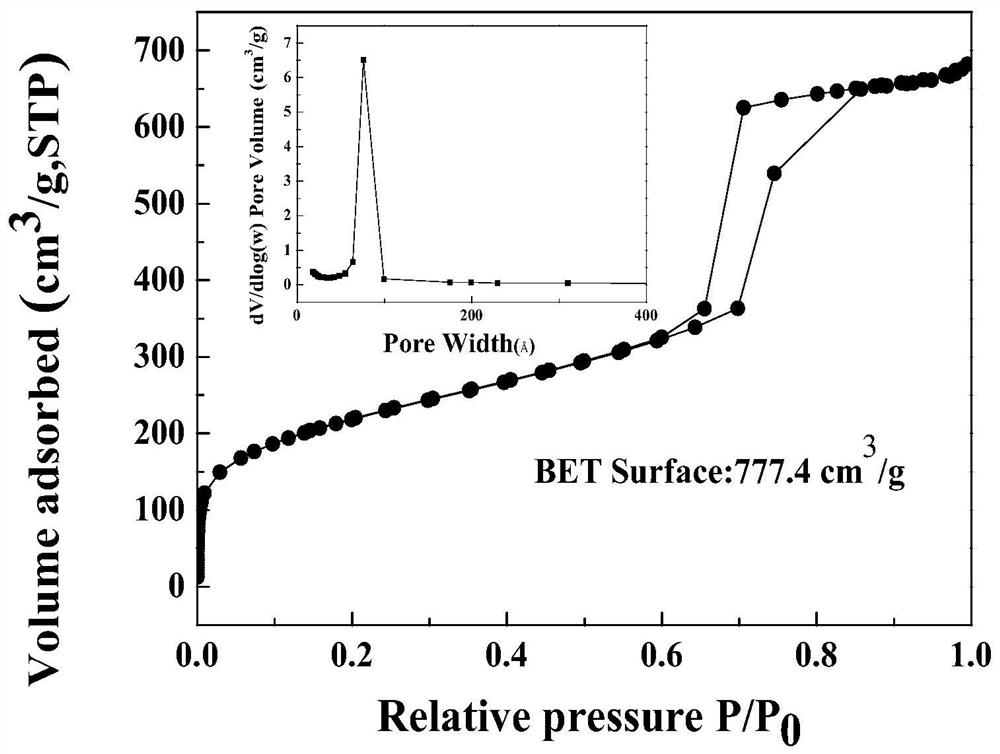

[0048] 2. Various characterizations of copper-doped SBA-15 mesoporous molecular sie...

Embodiment 2

[0064] Step 1: Add 0.01g Na 2 S 2 o 8 Dissolve in 15mL water, add 4.3g TEOS into a quartz tube, and stir for 40min under the irradiation of a UV lamp of 500W until the solution becomes clear and no stratification occurs to obtain the M solution;

[0065] Step 2: Dissolve 1.8g P123 in 85mL water, stir for 4 hours until completely dissolved, then add 0.6g Cu(Ac) 2 ·H 2 O is stirred to obtain N solution;

[0066] Step 3: Mix and stir the M solution and the N solution, form a suspension in a water bath at 25°C for 7 minutes, react for 12 hours, transfer the reaction product and mother liquor to polytetrafluoroethylene for crystallization at 110°C for 8 hours, wash with suction after cooling, and dry. Calcined at 550°C for 6h to obtain blue copper-doped SBA-15 mesoporous molecular sieve material.

[0067] The product was characterized by XRD, SEM, TEM, EDS, solid ultraviolet, physical adsorption and chemical adsorption analysis, which indicated that the copper-doped SBA-15 mes...

Embodiment 3

[0071] Step 1: Add 0.03g Na 2 S 2 o 8 Dissolve in 15mL of water, add 4.3g of TEOS into a quartz tube, and stir for 50min under the irradiation of a UV lamp of 300W until the solution is clear without stratification to obtain M solution;

[0072] Step 2: Dissolve 1.9g P123 in 85mL water, stir for 4 hours until completely dissolved, then add 1.0g Cu(Ac) 2 ·H 2 O is stirred to obtain N solution;

[0073] Step 3: Mix and stir the M solution and the N solution, form a suspension in a water bath at 35°C for 6 minutes, react for 10 hours, transfer the reaction product and the mother liquor to polytetrafluoroethylene at 100°C for crystallization for 10 hours, after cooling, filter, wash, and dry. Calcined at 550℃ for 6h to obtain dark blue copper-doped SBA-15 mesoporous molecular sieve material.

[0074] The product was characterized by XRD, SEM, TEM, EDS, solid ultraviolet, physical adsorption and chemical adsorption analysis, which indicated that the copper-doped SBA-15 mesopor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com