Preparation method of lithium ion battery cathode paste, lithium ion battery cathode plate and lithium ion battery

A technology for lithium ion battery and cathode slurry, applied in the field of lithium ion battery, can solve the problems of poor dispersion and consistency, poor stability of slurry, low equipment utilization rate, etc. The effect of short production times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In a first aspect, in at least one embodiment, a method for preparing a positive electrode slurry for a lithium-ion battery is provided, the method comprising the following steps:

[0042] Add the solvent and the binder into the glue tank and mix evenly to prepare glue, and send the glue into storage tank A for storage;

[0043] Add the glue, conductive agent and active material into the stirring tank, mix evenly to prepare the slurry to be treated, and send the slurry to be treated into the storage tank B for storage;

[0044] The slurry to be treated is sent to a high-speed dispersion system for treatment to obtain a positive electrode slurry for a lithium battery.

[0045] The invention solves the problems that the existing lithium-ion battery slurry has a long batching time and the mixing uniformity needs to be improved, so as to achieve the preparation of a slurry with uniform dispersion and long-term stable performance in a relatively short period of time.

[004...

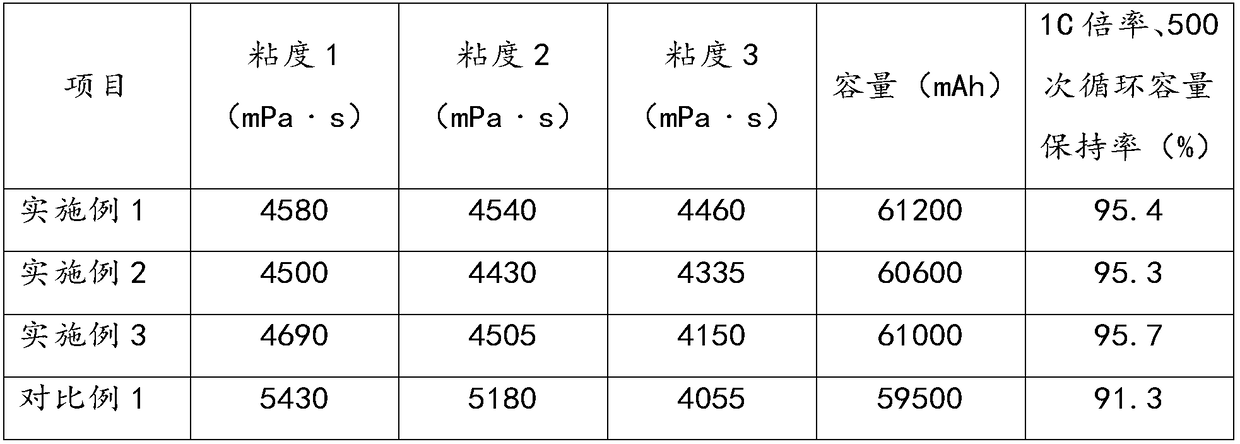

Embodiment 1

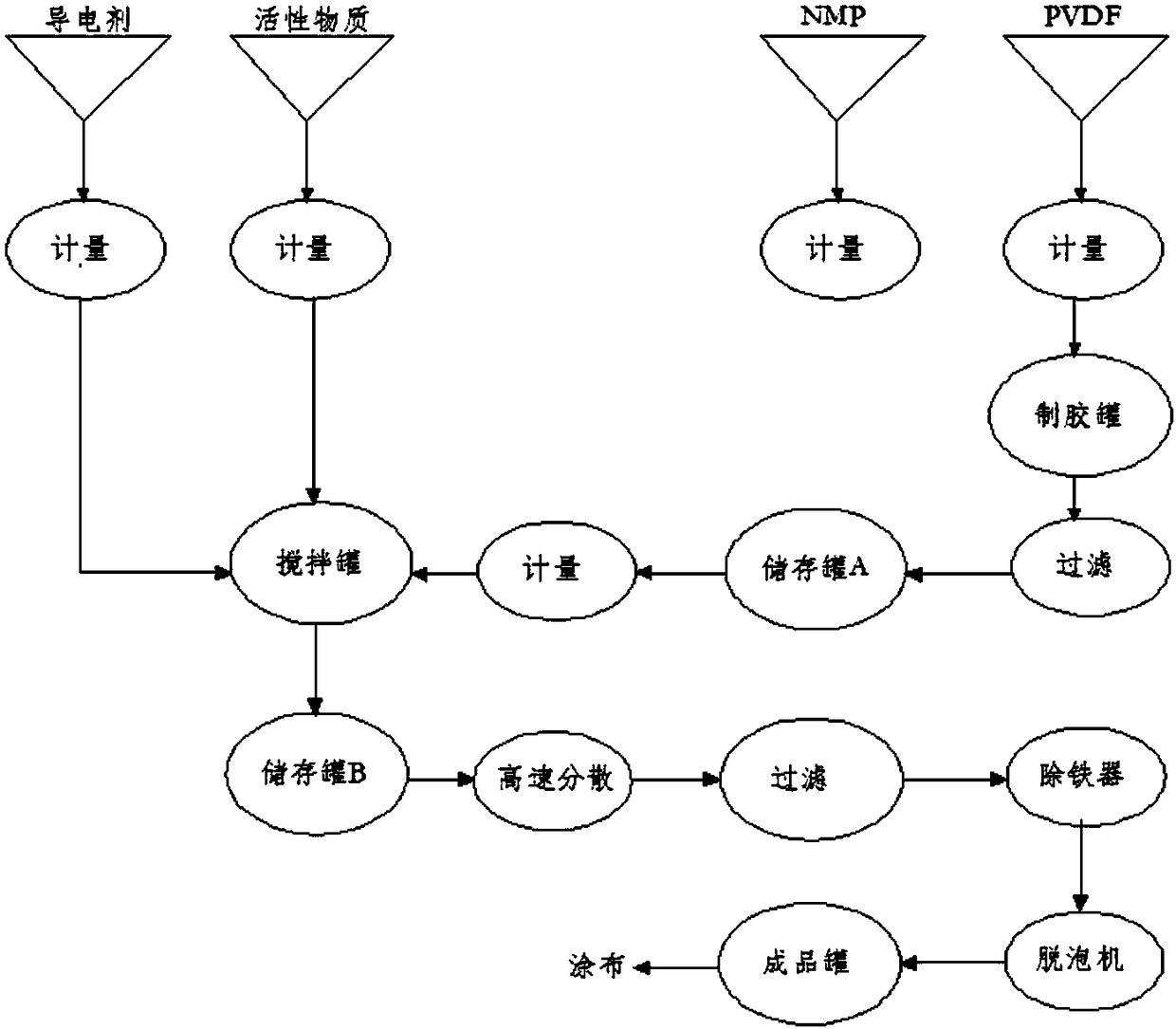

[0090] figure 1 The process flow diagram for the preparation of the positive electrode slurry for lithium-ion batteries provided by an embodiment of the present invention is shown, as figure 1 As shown, it mainly includes the following steps:

[0091] (a) Glue making: first add NMP to the glue making tank and stir to raise the temperature to 40°C, the stirring and heating time is 30 minutes, then add PVDF and stir for 90 minutes to make the glue, put the prepared glue into storage In tank A, it is used for homogenization; the mass ratio of NMP to PVDF is 12:1;

[0092] (b) Homogenization: Add the prepared glue and conductive agent into the stirring tank at the same time, stir for 10 minutes under the condition that the revolution and rotation speeds of the stirring tank are 15 rpm and 1000 rpm respectively, and then at a low speed Stirring means that the active substance is added to the stirring tank under the conditions of the revolution and rotation speeds of 10 rpm and 50...

Embodiment 2

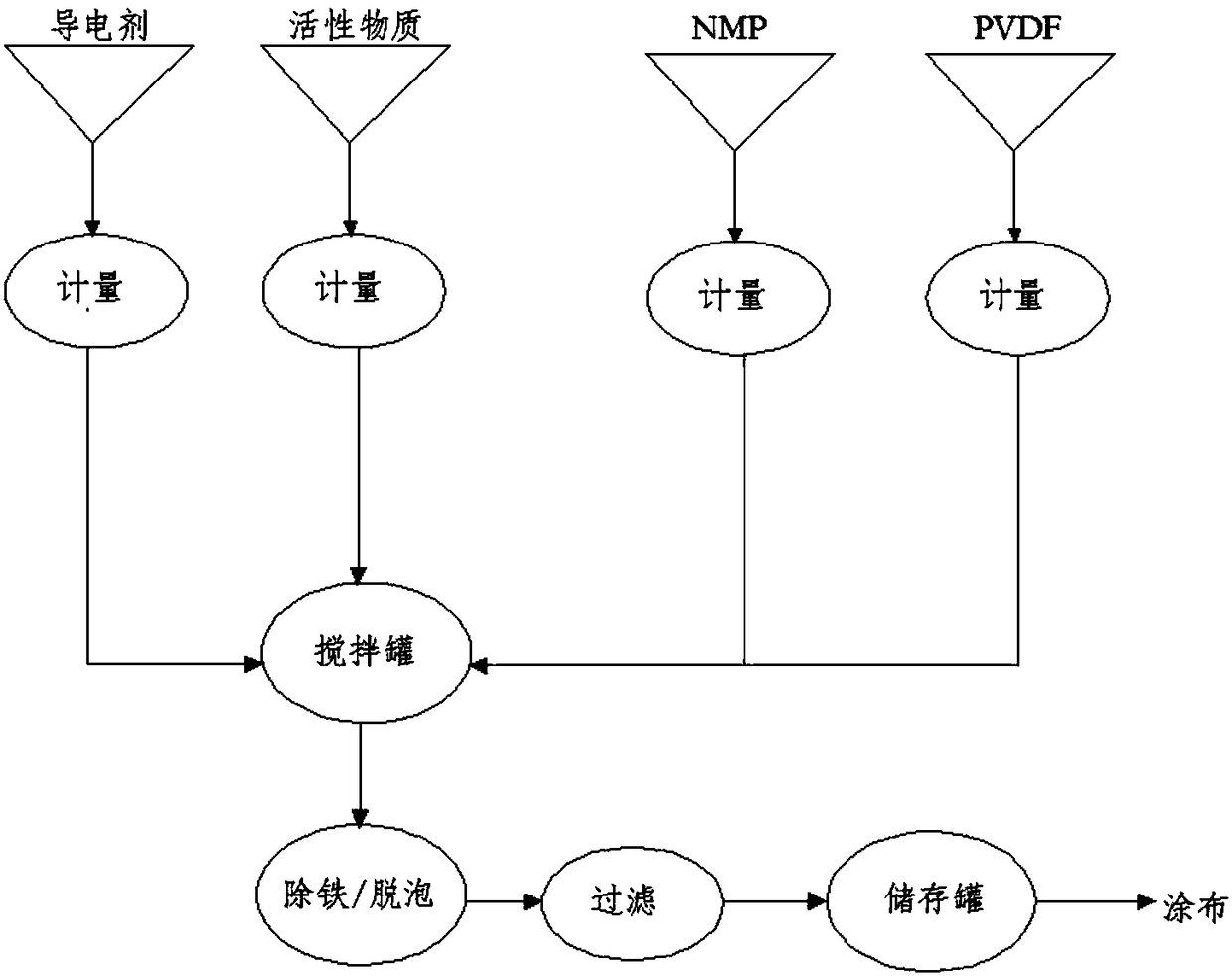

[0095] A preparation method of lithium ion battery positive electrode slurry mainly comprises the following steps:

[0096] (a) Glue making: First add NMP into the glue making tank and stir to raise the temperature to 35°C, the stirring and heating time is 25 minutes, then add PVDF and stir for 80 minutes to make the glue, put the prepared glue into storage In tank A, it is used for homogenization; the mass ratio of NMP to PVDF is 13:1;

[0097] (b) Homogenization: the prepared glue and conductive carbon black are added to the stirring tank simultaneously, and the revolution and rotation speed of the stirring tank are respectively 10 rev / min and 800 rev / min and stirred for 12min, then Low-speed stirring is to add lithium iron phosphate into the stirring tank under the conditions of revolution and rotation speeds of 10 rpm and 400 rpm respectively. The feeding time is 12 minutes. After the addition is completed, the rotation and revolution speeds are increased. Stir for anothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com