Automatic batching device

A technology of automatic batching and batching boxes, which is applied to feed, mixers with rotating stirring devices, mixer accessories, etc., and can solve problems such as extrusion and crushing of feed materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

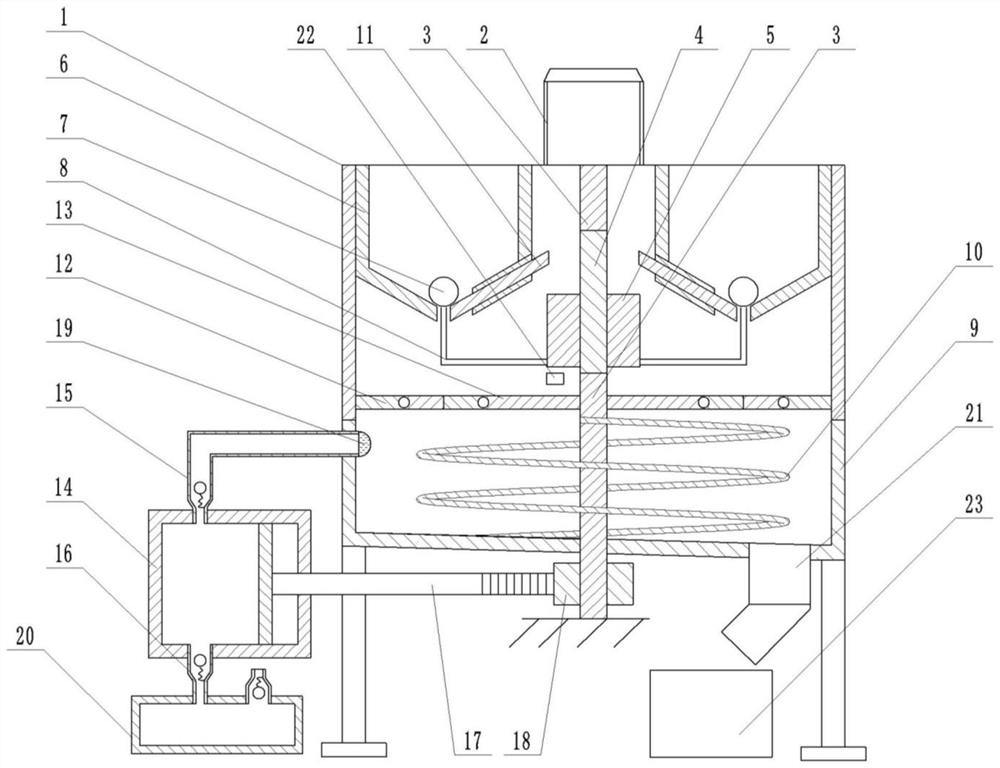

[0030] Example 1 substantially as attachment Figure 1-2 Down:

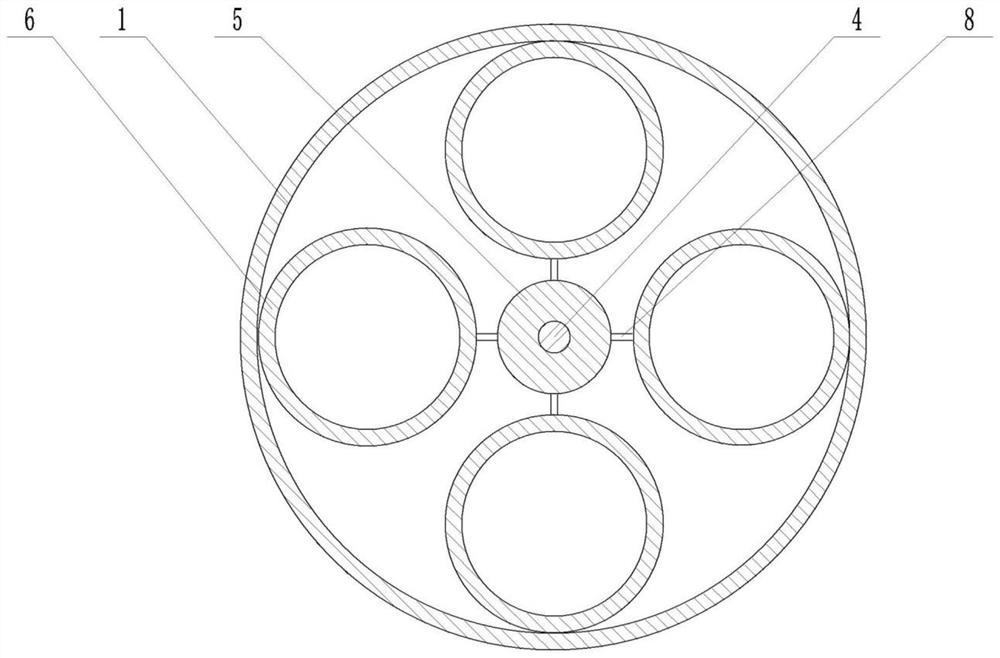

[0031] An automatic dosing device, comprising a frame 1, a motor 2 and feed mechanism, feed mechanism and the motor 2 are disposed on the frame 1, the ball screw 4 is connected, by a screw thread on the spindle motor 4 3 2 5 is connected to the slider; servo motor 2 motor 2, when the motor 2 is rotated forward, the ball screw shaft 3, and 4 is rotationally driven forward move the slider 5; reverse rotation when the motor 2, the rotary shaft 3 and the ball screw reverse rotation drive slide 4 5 down.

[0032] Feed means comprises a hopper 6, the ball 7 and the link 8, the bottom hopper 6 is provided with a funnel-shaped discharge opening, the ball 7 for opening and closing the discharge port, the ball 7 and the slider 5 through the connecting rod 8 connect. A plurality of feed means, a raw material feed port means for placing each of the different feed, when moving the slider 5, the hopper discharge opening 6 is opened...

Embodiment 2

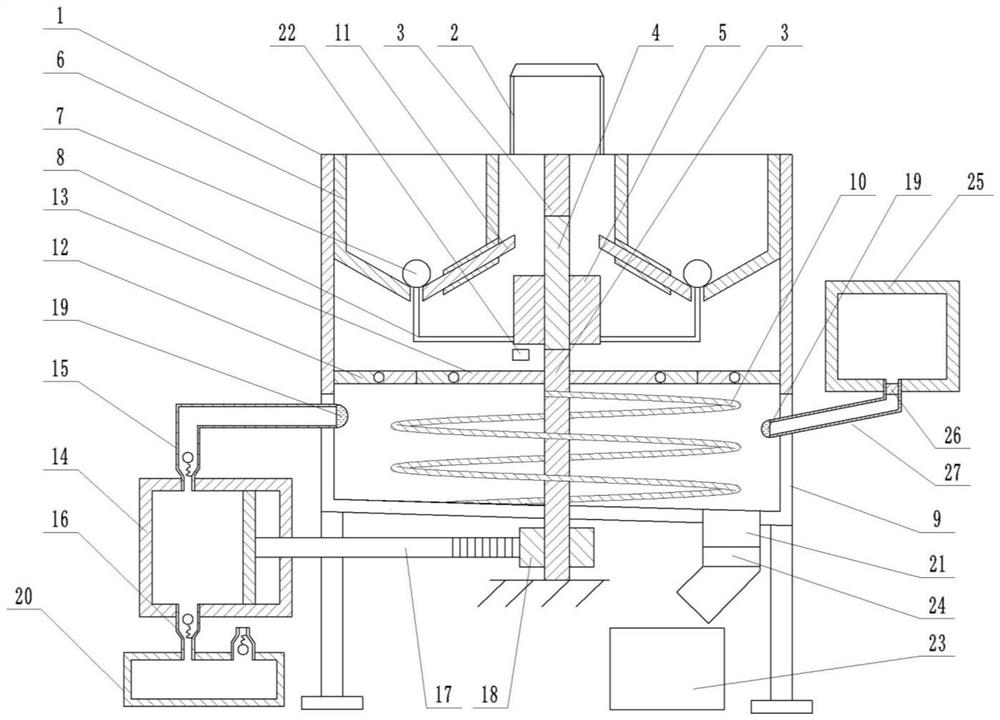

[0049] Compared with Example 1, the difference is only that Figure 3-4 As shown: Also included:

[0050] The destination acquisition module is used to obtain an estimated delivery address of this batch of feed; (specifically, the smartphone is used in this embodiment to obtain enterprise ERP information).

[0051] The stroke estimation module is used to calculate the difference time according to the current time and the expected delivery address; (specifically, the navigation module of the smartphone used in this embodiment, such as software tools such as Gao De Map, completed the expected delivery Time prediction, then derive the difference time according to the current time).

[0052] The second inoculation box 25, the second inoculation chamber 25 is fixed to the upper, and the second inoculation box 25 is contained in the same bacterial liquid in the casing 20, and the second inoculation box 25 is provided with the ingredient box 9. Further, the bacterial liquid can be formed ...

Embodiment 3

[0055] Example 3 Basic

[0056] The present embodiment is different from the first embodiment. Figure 5-6 As shown: Also included:

[0057] Acquisition module: Terrible parameters for acquisition within a year: The acquisition module includes temperature sensors and electronics, the chicken house includes the temperature of the chicken house and the weight of the feed to the chicken corresponding to the chicken at different temperatures. (Specifically The temperature sensor employed in this embodiment is a WZP-100 temperature sensor, which can quickly accurately induce temperature change, and measure the temperature sensor each time the temperature sensor is measured once; in this embodiment, the electronic scale is placed at the bottom of the feed slot, the electronic scale model is TCS-AE / AC, the weighing range is 0-75kg, and the scale is measured at 8 o'clock in the morning. It is measured at 20:00 in the evening. The electronic scale data and temperature detector data are up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com