Negative electrode of lithium ion battery, and lithium ion battery

A lithium-ion battery and negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of long batching time and complex negative electrode process, and achieve the effect of increasing energy density and shortening batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

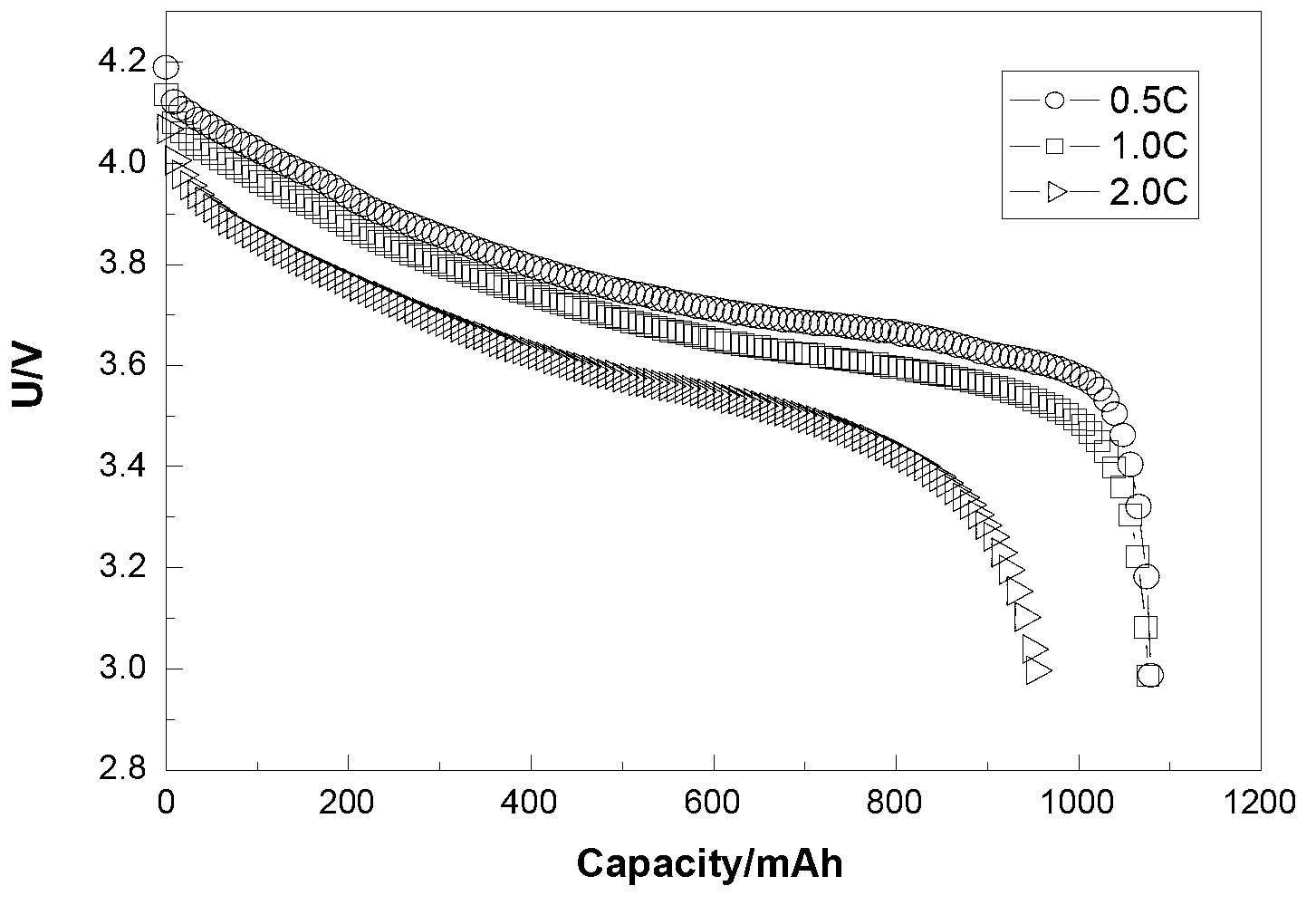

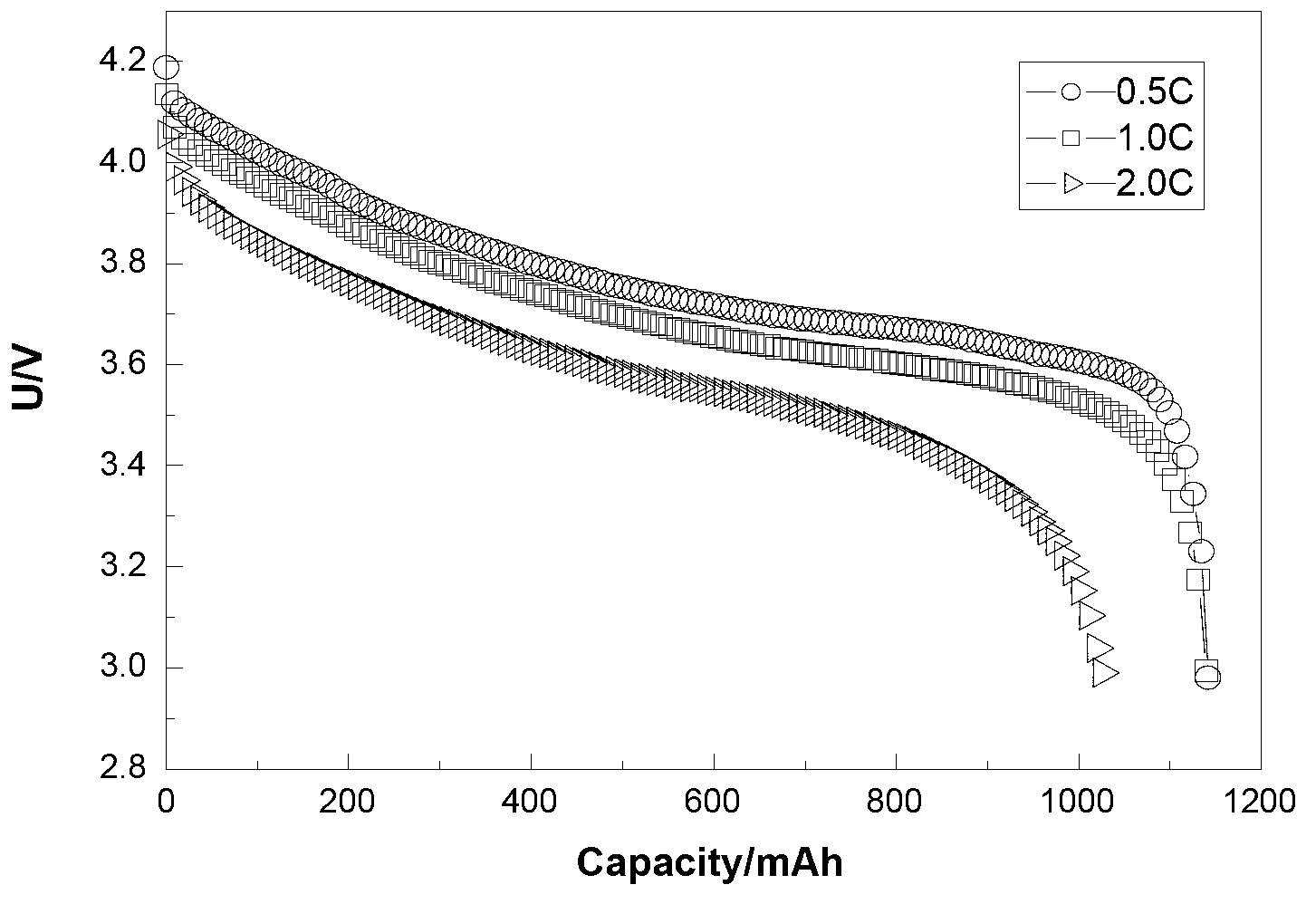

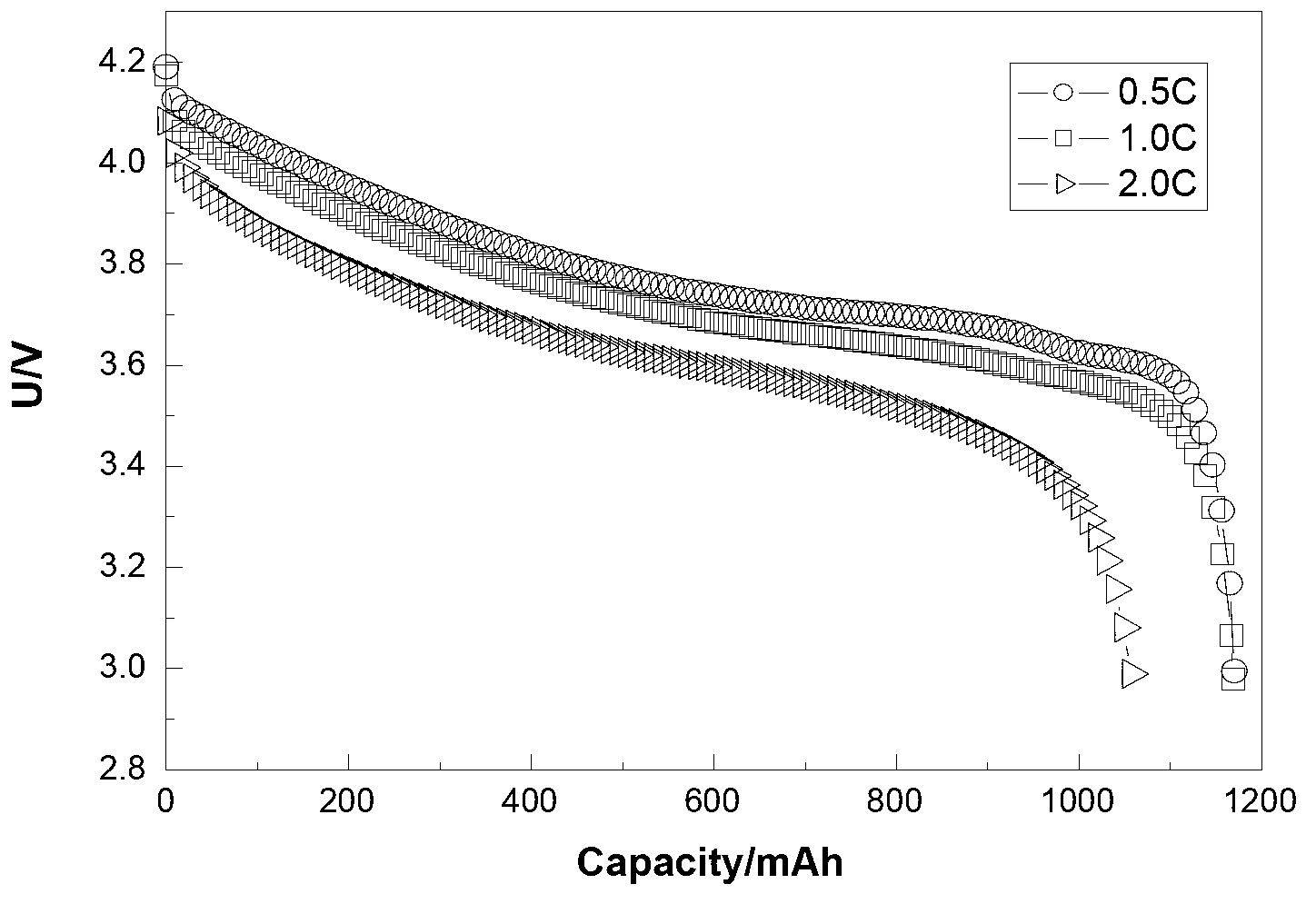

Image

Examples

preparation example Construction

[0040] The preparation steps of the negative electrode of lithium ion battery are:

[0041] (1) After the slurry passes through a 100-150 mesh screen, it is coated on the substrate with a coating machine and the coated film is dried to obtain a coated membrane. The density of the coated surface is 8.77±0.35mg / cm 2 ;

[0042] (2) The coated diaphragm is rolled with a pair of rollers, and the thickness of the diaphragm after rolling is controlled to 115±5μm;

[0043] (3) The rolled film is cut into small pieces of 459mm*43mm by cutting machine and slitting machine;

[0044] (4) Use a super welding machine to weld a nickel strip on the exposed foil area of the small chip head. The size of the nickel strip is: 40.5mm*3.0mm*0.1mm (length*width*thickness);

[0045] (5) Paste protective adhesive tape on the welded part to obtain the finished negative electrode of the lithium-ion battery.

Embodiment 1

[0047] Example 1: The negative electrode aqueous formula includes the following effective solid components, each effective solid component weight percentage is: negative electrode active material 51.83%, polyacrylonitrile type water-based conductive adhesive 1.62%, conductive agent 0.54%. In addition, the new high-performance negative electrode water-based formula also includes the following liquid components, the weight percentage of each liquid component is: deionized water 45.99%, N-methylpyrrolidone 0.01%, ethanol (defoamer) 0.01%.

[0048] Negative electrode slurry configuration method according to the present invention:

[0049] (1) Add deionized water and polyacrylonitrile-based water-based conductive adhesive (in no particular order) into the mixer, and stir for 5 minutes without vacuuming (revolution 20HZ, rotation 10HZ);

[0050] (2) Add conductive graphite, stir for 5 minutes without vacuuming, then vacuumize (vacuum degree -60KPa) and stir for 30 minutes (revolutio...

Embodiment 2

[0060] Example 2: The negative electrode aqueous formula includes the following effective solid components, each effective solid component weight percentage is: negative electrode active material 50.18%, polyacrylonitrile type water-based conductive adhesive 1.30%, conductive agent 0.53%. In addition, the new high-performance negative electrode water-based formula also includes the following liquid components, the weight percentage of each liquid component is: deionized water 45.74%, N-methylpyrrolidone 1.51%, isopropanol (defoamer) 0.74% (concentration ≥40%).

[0061] Negative electrode slurry configuration method according to the present invention:

[0062] (1) Add deionized water and polyacrylonitrile-based water-based conductive adhesive (in no particular order) to the mixer, vacuumize (vacuum degree -50KPa) and stir for 20min (revolution 30HZ, rotation 20HZ);

[0063] (2) Add conductive graphite, stir without vacuuming for 8 minutes, then vacuumize (vacuum degree -50KPa)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com