A pressure equalization calibration method for flat-flame burners in gas branch pipes of heating furnaces

A calibration method and flat-flame burner technology, applied in combustion methods, lighting and heating equipment, gas fuel burners, etc., can solve the problems of inaccurate and difficult calibration of flat-flame burner pressure in heating furnaces, and achieve effective Conducive to flue gas emission control, reduce gas consumption, and solve the effect of inaccurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

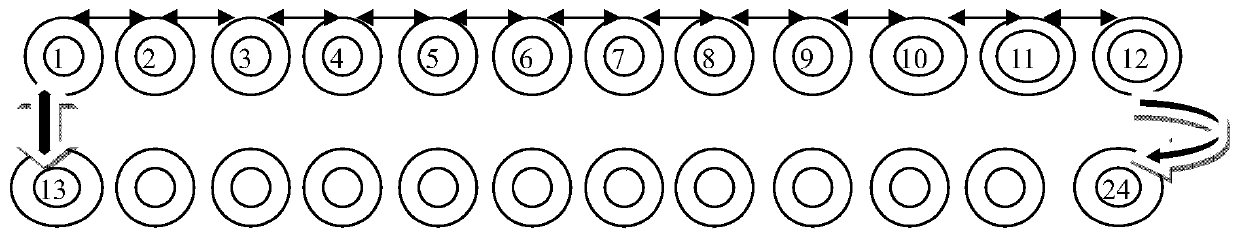

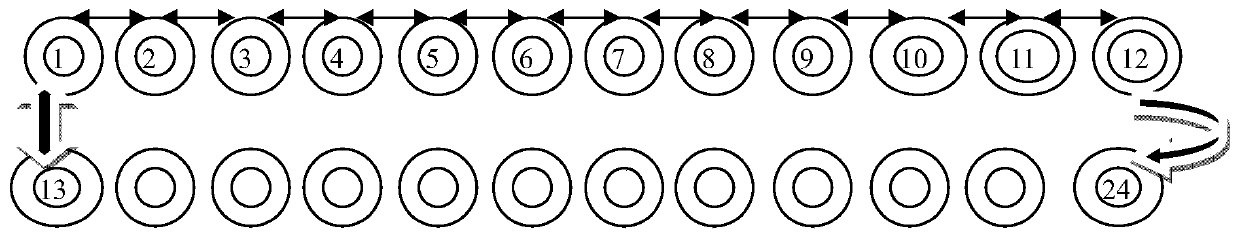

[0013] This embodiment is a heating furnace with a flat flame burner arrangement. The heating furnace in this embodiment is a full walking beam three-stage continuous heating furnace. The top area of the furnace adopts 84 double cross limiter control flat flame burners, and the bottom area adopts 10 digital pulse adjustable flame burners.

[0014] The pressure equalization calibration method for the flat flame burner of the heating furnace gas branch pipe of the present embodiment includes the following steps:

[0015] (1) When the heating furnace is in normal production state, the pressure of the gas main pipe is stable at the normal working pressure, open the main gas valve of the heating area that needs to be calibrated, and measure the gas pressure in this area after the hand valve of the branch pipe is above 3000Pa, so that the gas flow in this area can ensure the maximum gas flow consumption run;

[0016] (2) According to the fuel distribution ratio of each section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com