Hydraulic cylinder for discharging device

A discharge device and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve problems such as excessive impact force of workpieces, fast extension speed of hydraulic cylinders, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

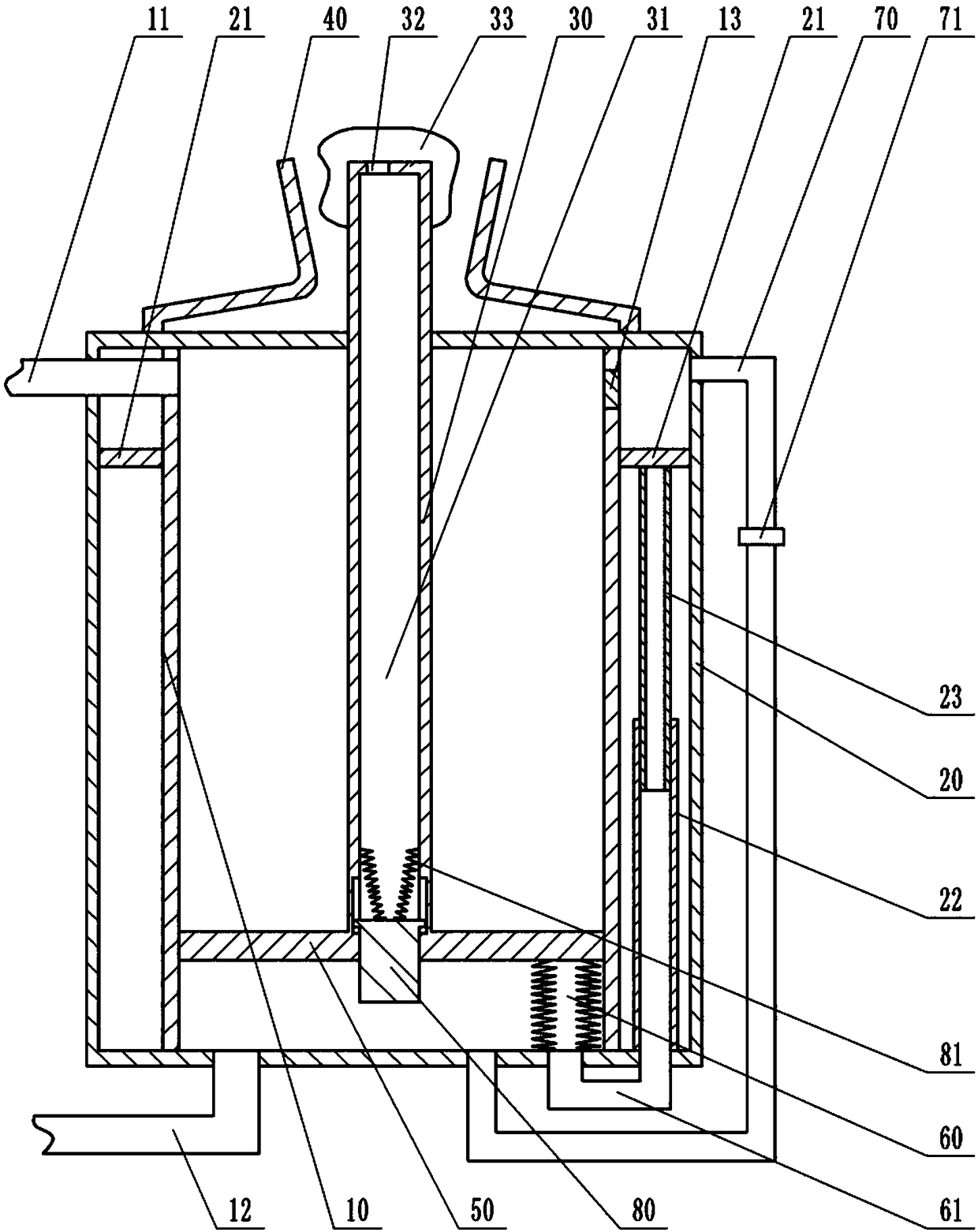

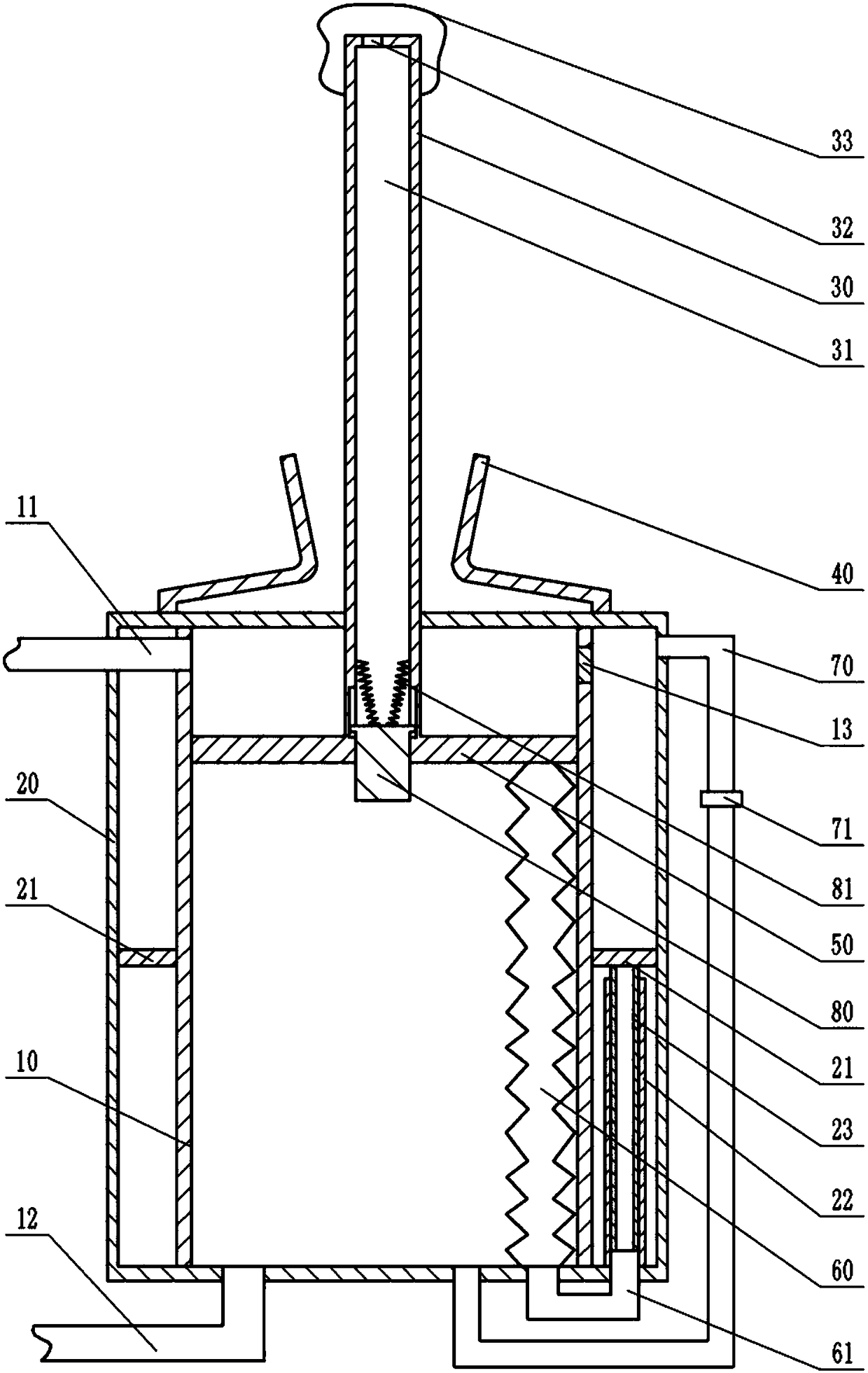

[0019] Instructions attached Figures 1 to 2 The reference signs in include: cylinder block 10, upper oil inlet passage 11, lower oil inlet passage 12, one-way oil discharge valve 13, outer cylinder 20, annular slide plate 21, fixed rod 22, sliding rod 23, piston rod 30, concave Cavity 31, through hole 32, air bag 33, sleeve 40, piston 50, rigid bellows 60, connecting pipe 61, oil pipe 70, one-way oil inlet valve 71, plunger 80, spring 81.

[0020] Such as figure 1 , figure 2 As shown, the hydraulic cylinder used for the discharge device includes a cylinder body 10, and the two ends of the cylinder body 10 are the cylinder bottom and the cylinder head respectively. The piston 50 is slid and sealed in the cylinder body 10, and the side of the piston 50 is fixed. There is a sealing ring attached to the inner wall of the cylinder body 10 . A piston rod 30 is fixed on the piston 50,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com