Crank-arm-type overhead working truck connector levelling hydraulic system

An aerial work vehicle and hydraulic system technology, applied in the field of hydraulic control, can solve the problems of partial vacuum, hidden dangers, inclination of the working platform 13, etc., and achieve the effect of ensuring synchronous movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

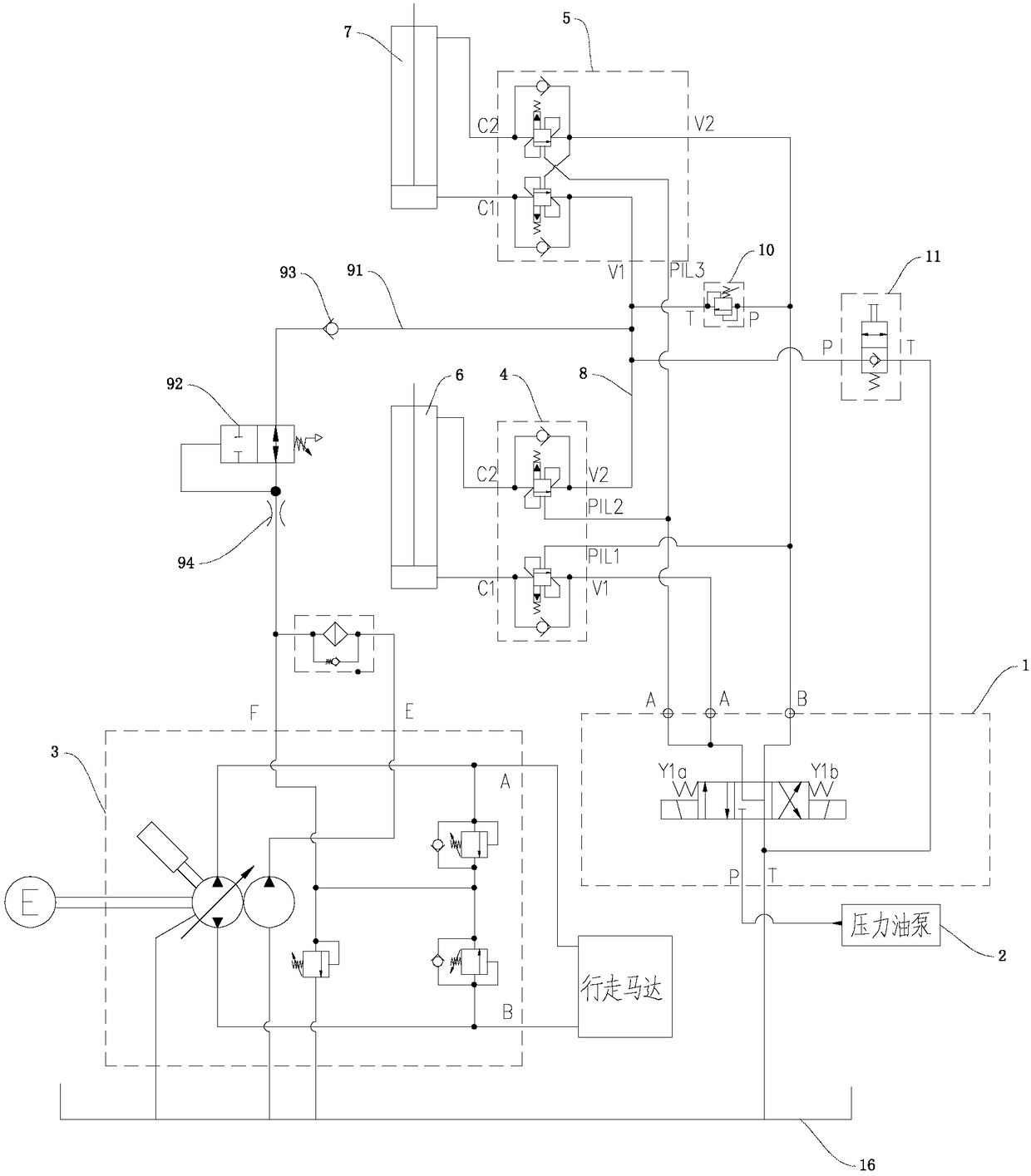

[0037] More preferably, refer to image 3 , the control valve 92 is an oil replenishing solenoid valve, and an electric control box 921 is arranged on the oil replenishing solenoid valve, and the electric control box 921 is electrically connected with the oil replenishing solenoid valve. This is the second implementation of the control valve 92. The staff inputs the program to the electric control box 921 to control the opening delay time of the electric control box 921. The delay time in this implementation is 5s. When starting up again after stopping, the electric control box 921 controls the oil supply solenoid valve to be energized, the oil supply solenoid valve spool reverses direction, and the oil supply line 91 is turned on. The reversing makes the oil supply line 91 cut off, avoiding the oil line of the oil charge pump from being connected with the closed cavity all the time, and realizing the automatic closing of the oil supply work.

[0038] Further preferably, a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com