Manufacturing method and structure of non-welded color steel door plate

A manufacturing method and technology of color steel plates, applied in the direction of doors, windows/doors, building components, etc., can solve the problems of high processing cost, excessive process, unsuitable for social development, etc., to improve mechanical properties, avoid surface treatment, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Embodiment 2: a kind of manufacturing method of weldless color steel door panel, comprises the following steps:

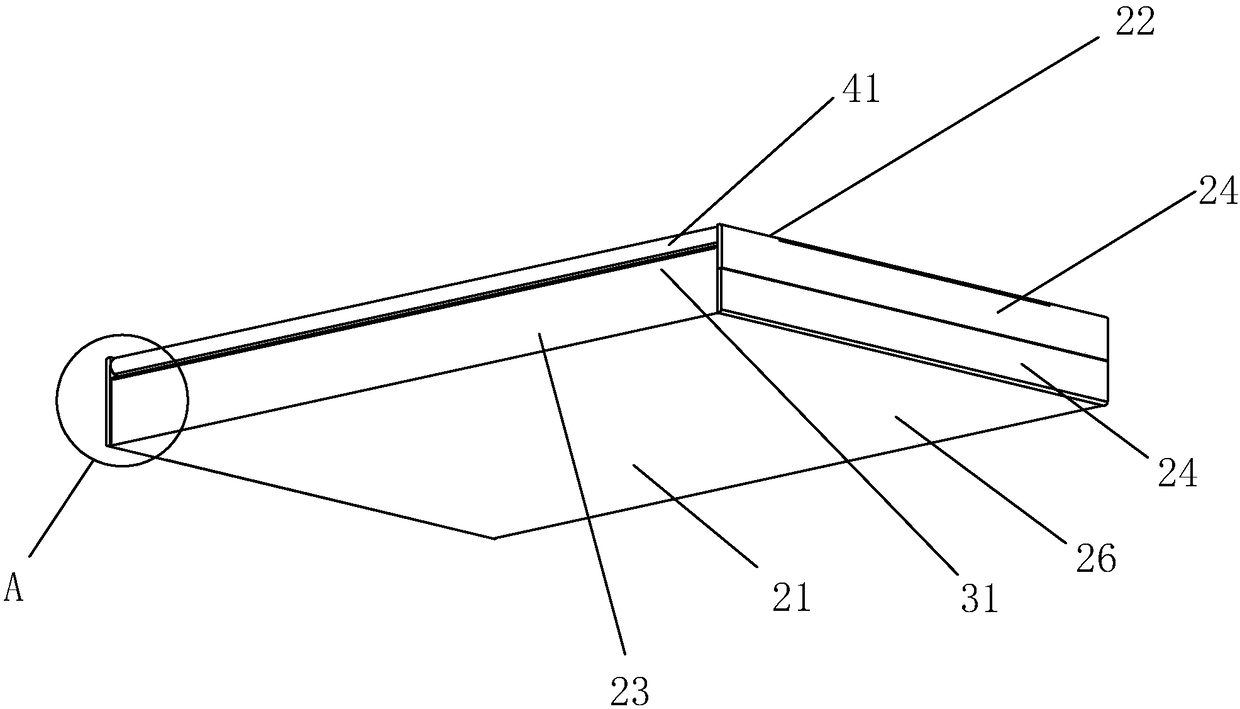

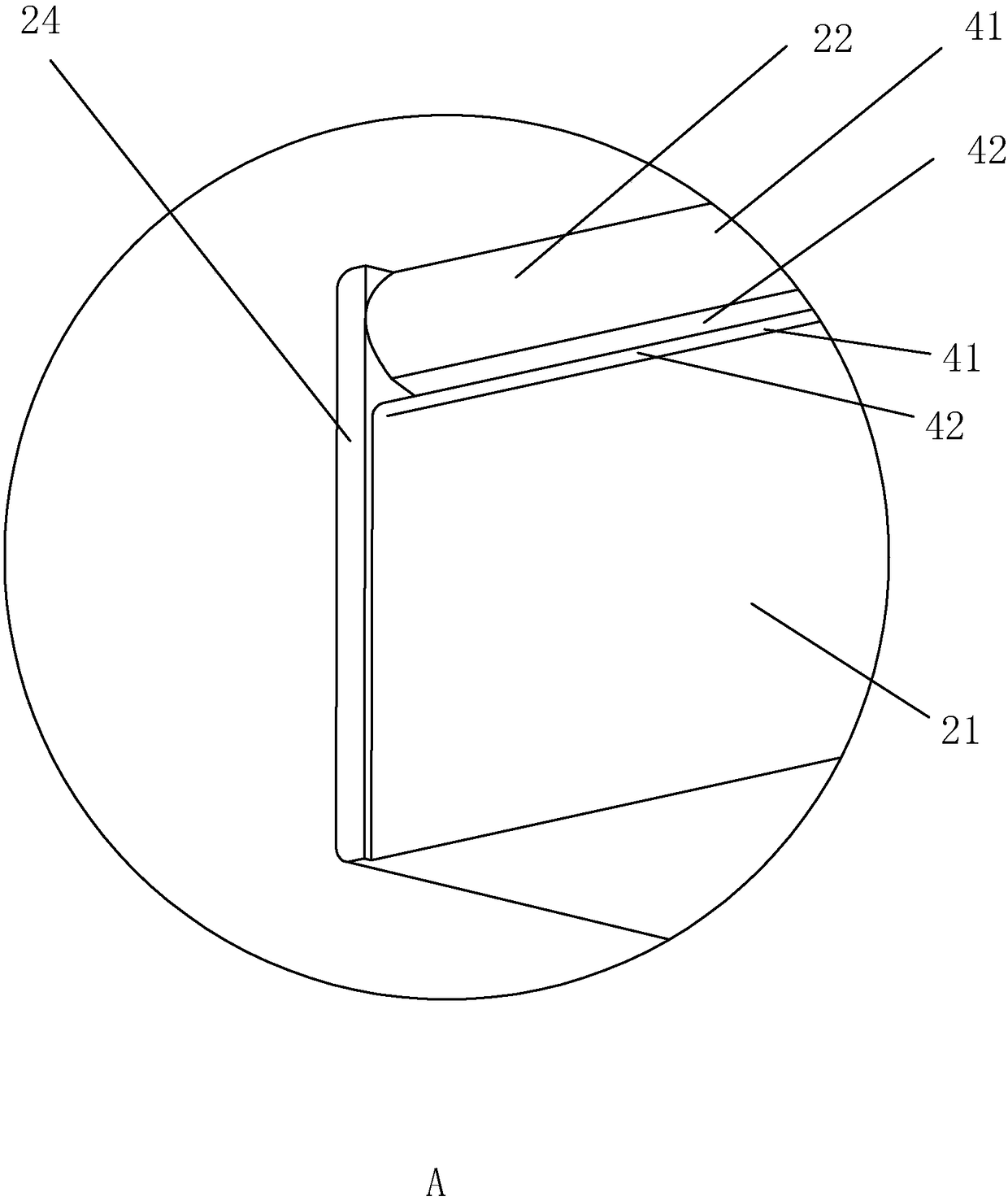

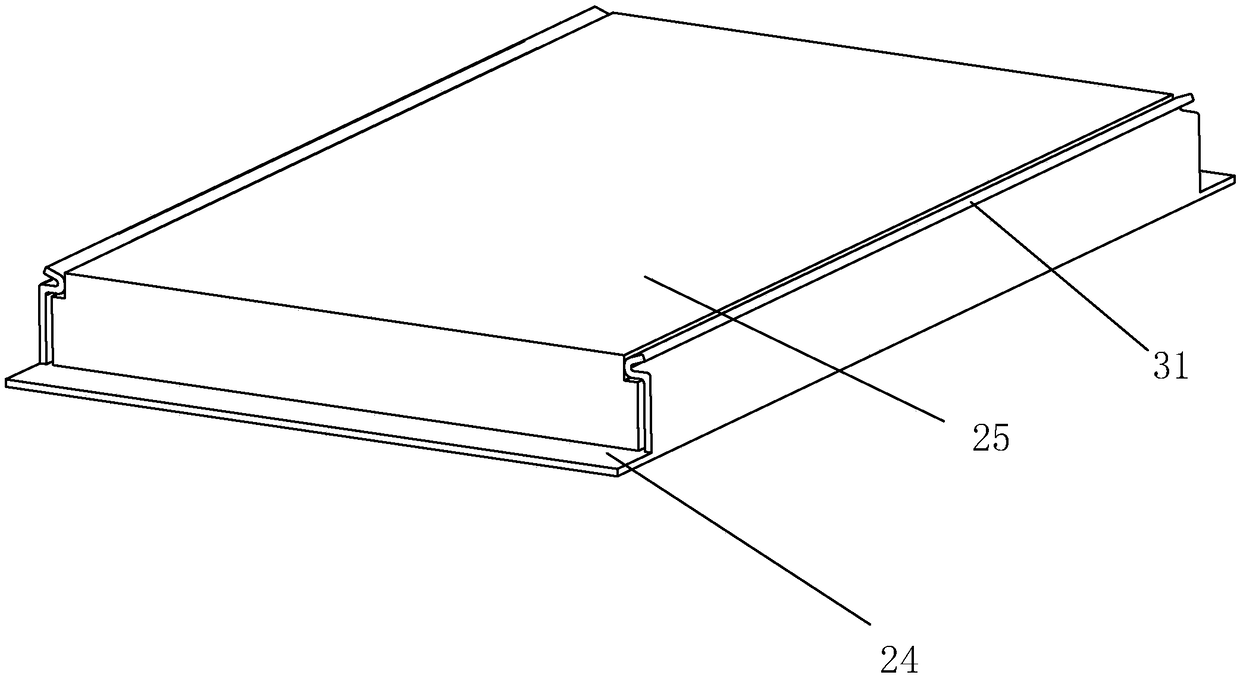

[0048] Step 1. Cut the surface-treated color steel plate according to the size, and the cutting is as follows Figure 6 structure shown, Figure 6 The left side of the center is the first color steel plate 21, and the right side is the second color steel plate 22. During the cutting process, there are remaining inserts 11 on both sides of the width direction of the first color steel plate 21 (for forming the first insert part 31), there are cladding surplus materials 12 (that is, vertical baffles 24) on both sides of the first color steel plate 21 in the length direction, and there are jamming surplus materials 11 on both sides of the second color steel plate 22 in the width direction (for Forming the second clamping part 41), the left side of the length direction of the second color steel plate 22 is covered with the remaining material 12 (that is, the ver...

Embodiment 3

[0054] Embodiment 3: a kind of manufacturing method of weldless color steel door panel, comprises the following steps:

[0055] Step 1. Cut the surface-treated color steel plate according to the size, and the cutting is as follows Figure 6 structure shown, Figure 6 The left side of the center is the first color steel plate 21, and the right side is the second color steel plate 22. During the cutting process, there are remaining inserts 11 on both sides of the width direction of the first color steel plate 21 (for forming the first insert part 31), there are cladding surplus materials 12 (that is, vertical baffles 24) on both sides of the first color steel plate 21 in the length direction, and there are jamming surplus materials 11 on both sides of the second color steel plate 22 in the width direction (for Forming the second clamping part 41), the left side of the length direction of the second color steel plate 22 is covered with the remaining material 12 (that is, the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com