Process for preparing fructose syrup from rice

A technology for high fructose syrup and rice, which is applied in the field of biological enzymolysis, can solve the problems affecting the conversion rate of saccharification and isomerization processes, difficult to control product quality, and small rice starch molecules, so as to achieve simple and easy processing steps and ensure stable quality. The effect of good sex and color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Washing and soaking: Wash the rice twice, then soak the rice in water at 35-40°C for 3-4 hours;

[0030] (2) Refining and pulping: the soaked rice is refined with a refiner, the concentration of the rice pulp is controlled at 19-20 ° Be', the crushed particle size is controlled at 60-80 mesh, and citric acid and sodium carbonate are used to Adjust the pH value of rice milk to 5.8-6.0 to obtain rice starch milk;

[0031] (3) Liquefaction: Add high-temperature α-amylase to the prepared rice starch milk, stir evenly and send it into the liquefaction tank. The liquefaction temperature is controlled at 105-110°C, and the liquefaction pressure is controlled at 0.5-0.8MPa. One iodine reaction, the liquefaction ends when the iodine reaction turns brownish red or red;

[0032] (4) Saccharification: Add dilute hydrochloric acid solution to the prepared liquefied liquid to adjust the pH value to 4.2-4.5, and add glucoamylase, stir evenly and send it to the saccharification ta...

Embodiment 2

[0042] (1) Washing and soaking: Wash the rice twice, then soak the rice in water at 35-40°C for 3-4 hours;

[0043] (2) Refining and pulping: the soaked rice is refined with a refiner, the concentration of the rice pulp is controlled at 19-20 ° Be', the crushed particle size is controlled at 60-80 mesh, and citric acid and sodium carbonate are used to Adjust the pH value of rice milk to 5.8-6.0 to obtain rice starch milk;

[0044] (3) Liquefaction: Add high-temperature α-amylase to the prepared rice starch milk, stir evenly and send it into the liquefaction tank. The liquefaction temperature is controlled at 105-110°C, and the liquefaction pressure is controlled at 0.5-0.8MPa. One iodine reaction, the liquefaction ends when the iodine reaction turns brownish red or red;

[0045] (4) Saccharification: Add dilute hydrochloric acid solution to the prepared liquefied liquid to adjust the pH value to 4.2-4.5, and add glucoamylase, stir evenly and send it to the saccharification ta...

Embodiment 3

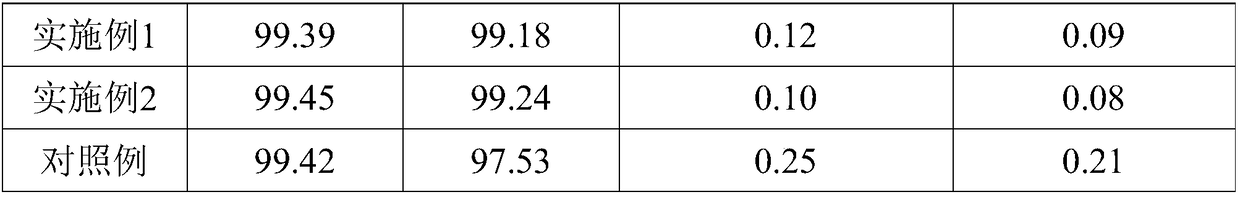

[0066] Using Example 1, Example 2, and Comparative Example, the same batch of rice was made into high-fructose syrup, and the decolorization and desalination effects were measured. The results are shown in Table 1.

[0067] The decolouring and desalting effect of table 1 decoloring and desalting agent of the present invention

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com