Full-element bio-organic fertilizer specially used for producing high-yield camellia oleifera, and preparation method of bio-organic fertilizer

A bio-organic fertilizer and high-yield technology, which is applied in the field of whole-element bio-organic fertilizer for Camellia oleifera high-yield and its preparation, can solve problems such as extensive management, low yield of camellia oleifera fruit, and poor soil in camellia oleifera forests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

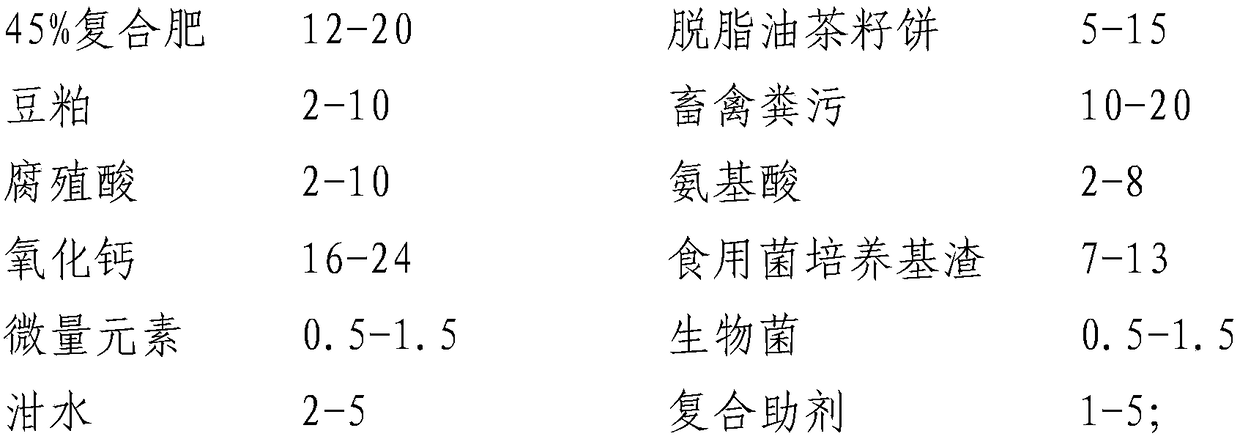

Method used

Image

Examples

Embodiment 1

[0053] The whole element bio-organic fertilizer special for Camellia oleifera high yield of the present embodiment, its preparation process is as follows:

[0054] (1) Prepare materials: according to parts by weight, get 12 parts of 45% compound fertilizer, 5 parts of defatted camellia seed cake, 10 parts of soybean meal, 20 parts of livestock and poultry manure, 10 parts of humic acid, 2 parts of amino acid, 16 parts of calcium oxide, 7 parts of edible mushroom culture medium slag, 0.5 parts of trace elements (including vanadium, selenium, calcium, magnesium, sulfur, iron, zinc, boron, manganese, copper, molybdenum, nickel) of equal weight, biological bacteria (including Nitrogen-fixing bacteria, phosphorus solubilizing bacteria, potassium solubilizing bacteria, bacillus, actinomycetes 5406, saccharomyces) 1.5 parts, swill 5 parts, compound additives 5 parts, spare;

[0055] The above composite additives are prepared by the following method: crush silicate substances (includi...

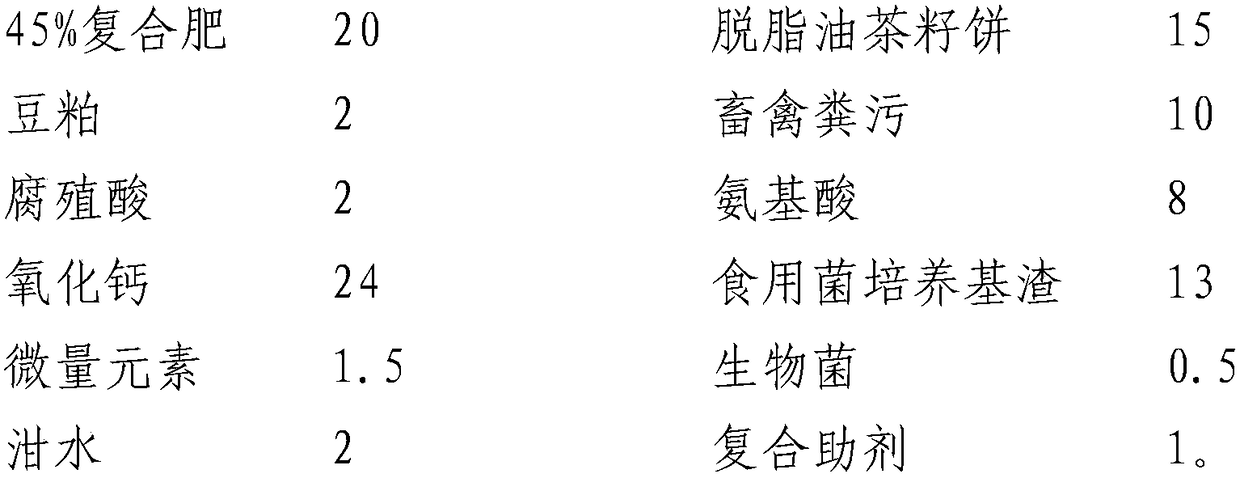

Embodiment 2

[0067] The whole element bio-organic fertilizer special for Camellia oleifera high yield of the present embodiment, its preparation process is as follows:

[0068] (1) Prepare materials: according to parts by weight, get respectively 20 parts of 45% compound fertilizer, 15 parts of defatted camellia seed cake, 2 parts of soybean meal, 10 parts of livestock and poultry manure, 2 parts of humic acid, 8 parts of amino acid, 24 parts of calcium oxide, 13 parts of edible mushroom medium slag, 1.5 parts of trace elements (including vanadium, selenium, calcium, magnesium, sulfur, iron, zinc, boron, manganese, copper, molybdenum, nickel) of equal weight, biological bacteria (including Nitrogen-fixing bacteria, phosphorus solubilizing bacteria, potassium solubilizing bacteria, bacillus, actinomycetes 5406, saccharomyces) 0.5 parts, swill 2 parts, compound auxiliary agent 1 part, spare;

[0069] Others are the same as in Example 1.

Embodiment 3

[0071] (1) Prepare materials: according to parts by weight, get 16 parts of 45% compound fertilizer, 10 parts of defatted camellia seed cake, 6 parts of soybean meal, 15 parts of livestock and poultry manure, 6 parts of humic acid, 5 parts of amino acids, 20 parts of calcium oxide, 10 parts of edible mushroom culture medium slag, 1 part of trace elements (including vanadium, selenium, calcium, magnesium, sulfur, iron, zinc, boron, manganese, copper, molybdenum, nickel) of equal weight, biological bacteria (including Nitrogen-fixing bacteria, phosphorus solubilizing bacteria, potassium solubilizing bacteria, bacillus, actinomycetes 5406, saccharomyces) 1 part, swill 4 parts, compound auxiliary agent 3 parts, spare;

[0072] Others are the same as in Example 1.

[0073] The high-yield whole element bio-organic fertilizer for camellia oleifera of the invention is specially used for planting camellia oleifera in southern my country. See Table 2 below for its application amount, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com