Lanthanum strontium manganese oxide ceramic film with conductive function and preparation method thereof, titanium-based lanthanum strontium manganese oxide ceramic electrode for flow battery

A technology of lanthanum strontium manganese oxide ceramics and thin films, which is applied in the field of new energy and new materials preparation, can solve the problems of limited application, the uniformity of electrical conductivity is not as good as that of metal materials, and poor electrochemical reversibility of electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

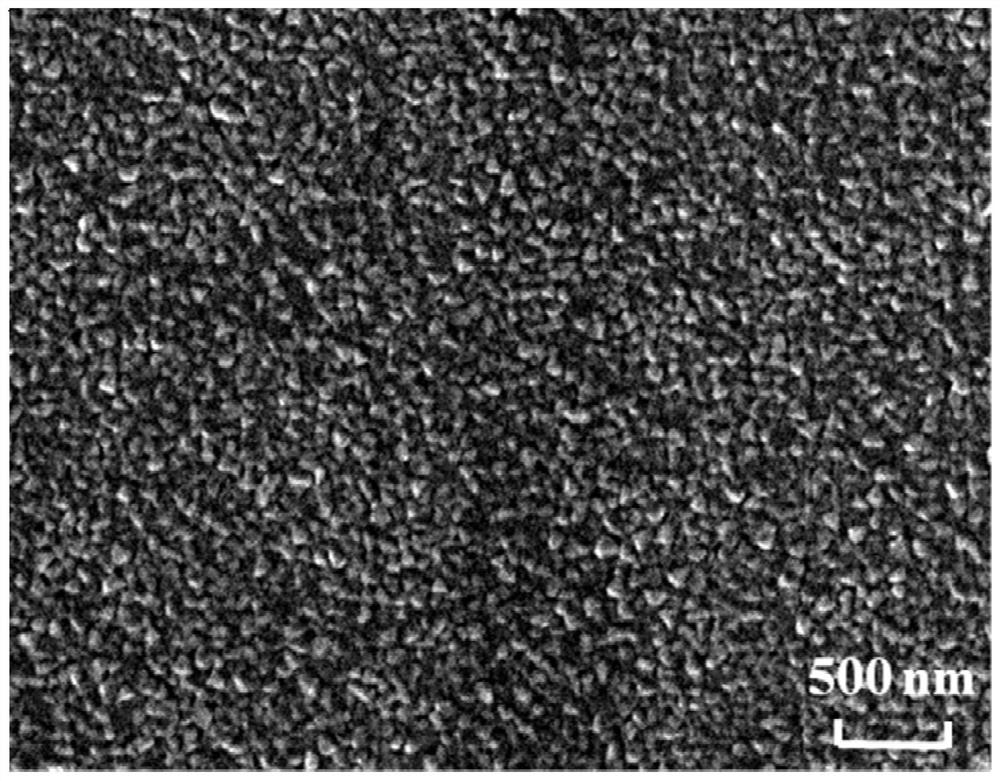

Image

Examples

Embodiment 1

[0031] A titanium-based lanthanum strontium manganese oxide ceramic electrode for a flow battery of the present invention comprises a titanium substrate and a lanthanum strontium manganese oxide ceramic thin film on the surface of the titanium substrate.

[0032] The preparation method of the titanium-based lanthanum strontium manganese oxide ceramic electrode of the present embodiment comprises the following steps:

[0033] (1) Choose a titanium plate as the titanium substrate, polish and polish it with 40, 500 and 1200 mesh sandpaper respectively, and then wash it with acetone and deionized water in turn; then put it into a 40% NaOH aqueous solution and soak it at 80°C for 2 hours , and then moved into a 15% oxalic acid solution boiling at 98°C for 2 hours. Finally, ultrasonic cleaning was performed in acetone and deionized water for 10 minutes, and dried for later use.

[0034] (2) Preparation of lanthanum strontium manganese oxygen sol

[0035] (2.1) Add strontium acetat...

Embodiment 2

[0049] A titanium-based lanthanum strontium manganese oxide ceramic electrode for a flow battery of the present invention comprises a titanium substrate and a lanthanum strontium manganese oxide ceramic thin film on the surface of the titanium substrate.

[0050] The preparation method of the titanium-based lanthanum strontium manganese oxide ceramic electrode of the present embodiment comprises the following steps:

[0051] (1) Choose a titanium plate as the titanium substrate, polish and polish it with 40, 500 and 1200 mesh sandpaper respectively, and then wash it with acetone and deionized water in turn; then put it into a 40% NaOH aqueous solution and soak it at 80°C for 2 hours , and then moved into a 15% oxalic acid solution boiling at 98°C for 2 hours. Finally, ultrasonic cleaning was performed in acetone and deionized water for 10 minutes, and dried for later use.

[0052] (2) Preparation of lanthanum strontium manganese oxygen sol

[0053] (2.1) Add strontium acetat...

Embodiment 3

[0064] A titanium-based lanthanum strontium manganese oxide ceramic electrode for a flow battery of the present invention comprises a titanium substrate and a lanthanum strontium manganese oxide ceramic thin film on the surface of the titanium substrate.

[0065] The preparation method of the titanium-based lanthanum strontium manganese oxide ceramic electrode of the present embodiment comprises the following steps:

[0066] (1) Choose a titanium plate as the titanium substrate, polish and polish it with 40, 500 and 1200 mesh sandpaper respectively, and then wash it with acetone and deionized water in turn; then put it into a 40% NaOH aqueous solution and soak it at 80°C for 2 hours , and then moved into a 15% oxalic acid solution boiling at 97°C for 2 hours. Finally, ultrasonic cleaning was performed in acetone and deionized water for 10 minutes, and dried for later use.

[0067] (2) Preparation of lanthanum strontium manganese oxygen sol

[0068] (2.1) Add strontium acetat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com