High-speed intelligent stamping system for shanks for footwear

A steel shank, high-speed technology, applied in the field of high-speed intelligent systems, can solve problems such as large product demand, achieve high feeding accuracy, simple operation, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to achieve the above object, the technical scheme to be used in the present invention is as follows.

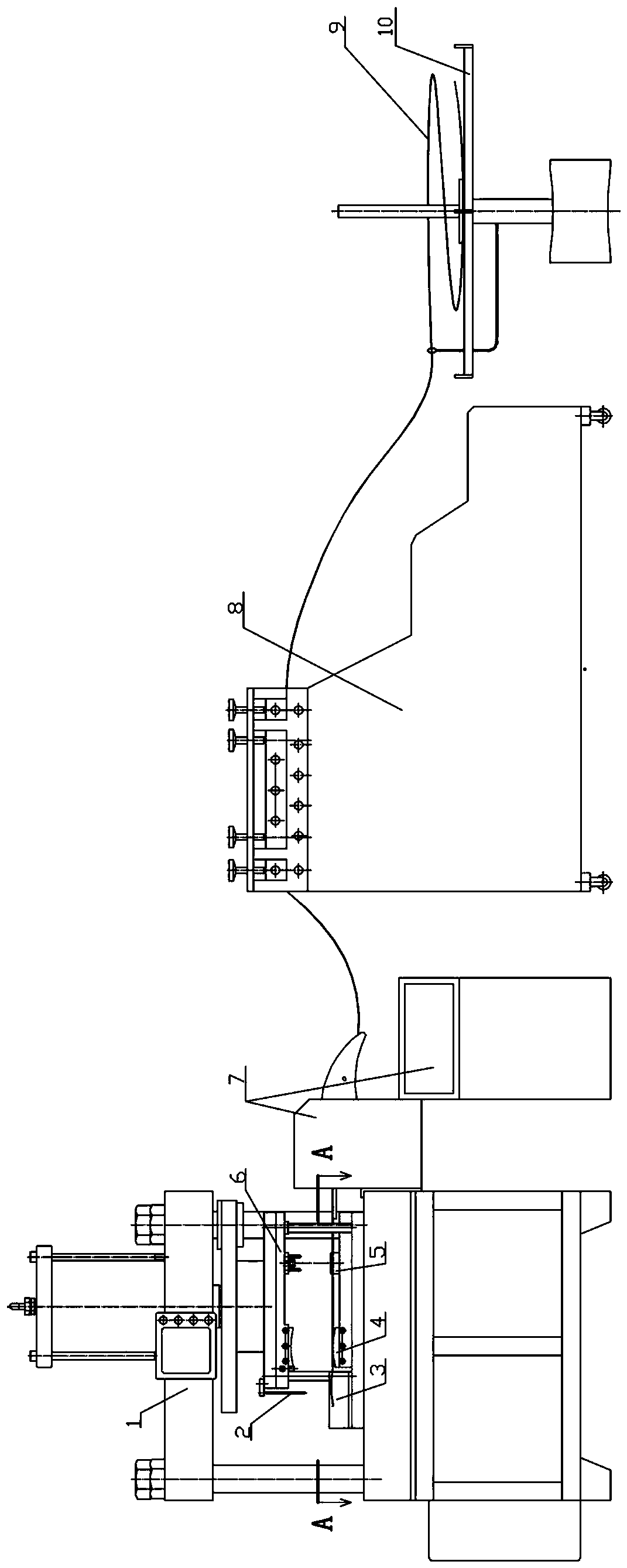

[0026] Such as figure 1 As shown, the high-speed intelligent stamping system for shoe steel shanks, the system includes a hydraulic press 1, a servo feeder 7, and a leveling machine 8 arranged in sequence from left to right. The hydraulic press is equipped with an automatic swinging mold frame 6. The hydraulic press 1 is a hydraulic cylinder vertically arranged punching equipment, and the middle plate at the lower end of the piston rod of the hydraulic cylinder is equipped with an automatic swinging mold frame 6 with a punch and a forming die 4 . The workbench directly below the automatic swinging mold base 6 is equipped with a punching die 5 corresponding to the upper mould, a forming die 4 for pressing the arc of the shank.

[0027] The punching die 5 is provided with a limiting block through which the material strip 9 passes, and the limiting block can ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com