Protein-based foaming toothpaste composition

A composition, technology of toothpaste, applied in the direction of dentistry, medical science, oral care, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In a specific embodiment, the preparation method comprises:

[0051] (1) Disperse flavoring agent, sweetener, buffer, preservative, NaCl in water;

[0052] (2) dispersing the antioxidant in the solution obtained in step (1);

[0053] (3) dispersing calcium caseinate or its mixture with edible protein in the solution obtained in step (2);

[0054] (4) disperse the mixed thickener and abrasive in the solution obtained in step (3);

[0055] (5) The product obtained in (4) was degassed to obtain a toothpaste composition.

[0056] The toothpaste composition of the present invention can be adapted to different preparation methods or / devices, as long as the components of the toothpaste composition are fully and uniformly mixed.

[0057] Mixing can be achieved by stirring. There is no special requirement for the stirring temperature, as long as the components remain in a stable state at this temperature, and no volatilization, degradation, denaturation, aging, etc. will occ...

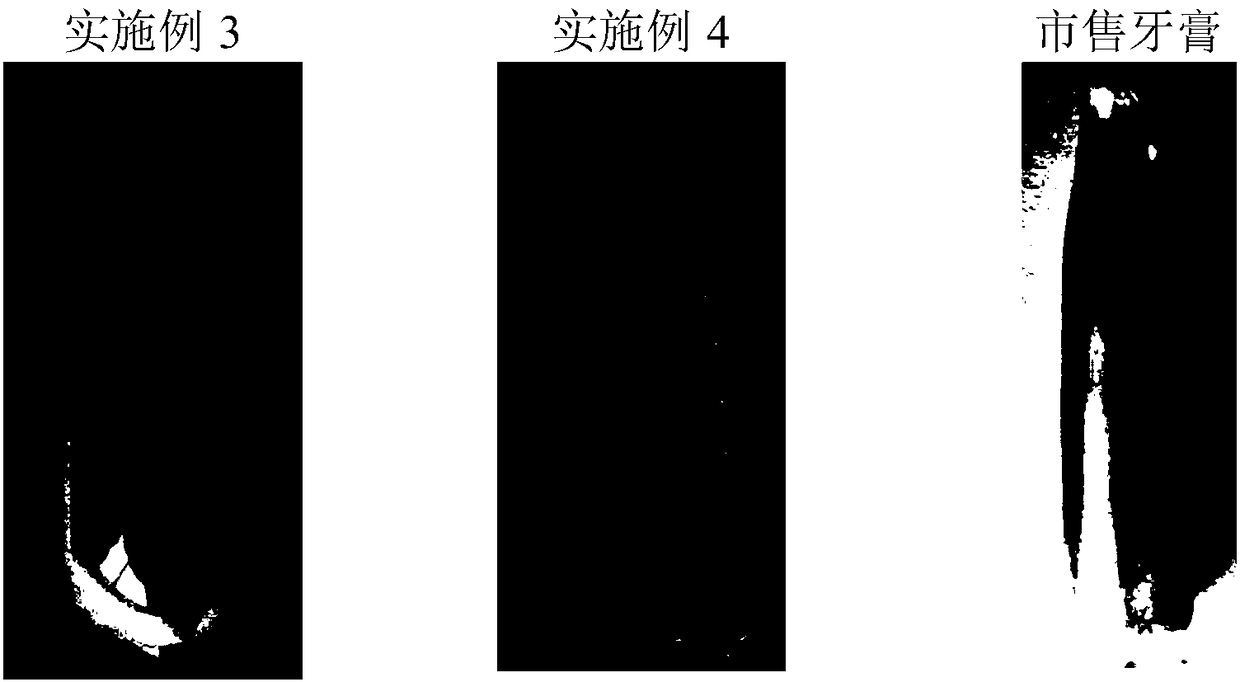

Embodiment 1-4

[0068] Preparation

[0069] Toothpaste compositions were prepared as follows.

[0070] (1) Mix and disperse maltose, citric acid, stevioside, paraben, mint essence and NaCl in water;

[0071] (2) dispersing tea polyphenols in the solution obtained in step (1);

[0072] (3) Add calcium caseinate, sodium caseinate or casein into the solution obtained in step (2), and stir at 2000 rpm for 5 minutes to disperse evenly;

[0073] (4) Add fully mixed xanthan gum, sodium carboxymethylcellulose, and silicon dioxide to the solution obtained in step (3), and stir at 4000rpm for 10min to fully disperse;

[0074] (5) The product of the above step (4) is degassed.

[0075] The ingredient content and performance parameters of the product are as shown in Table 1, wherein except the ingredients listed in the table, each product includes the following ingredients (% by weight):

[0076] Xanthan Gum: 0.5, Sodium Carboxymethyl Cellulose: 0.5, SiO 2 -MII: 18, 80% concentration (weight / weight)...

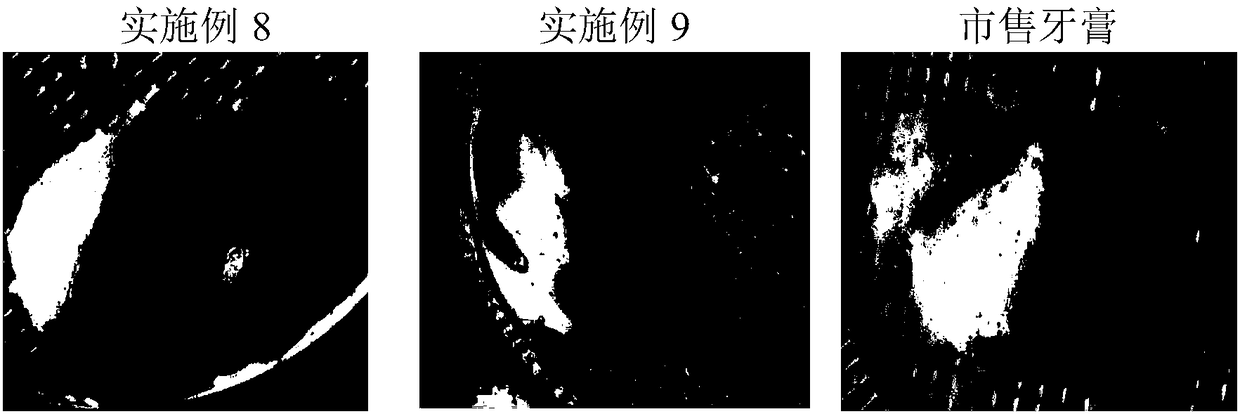

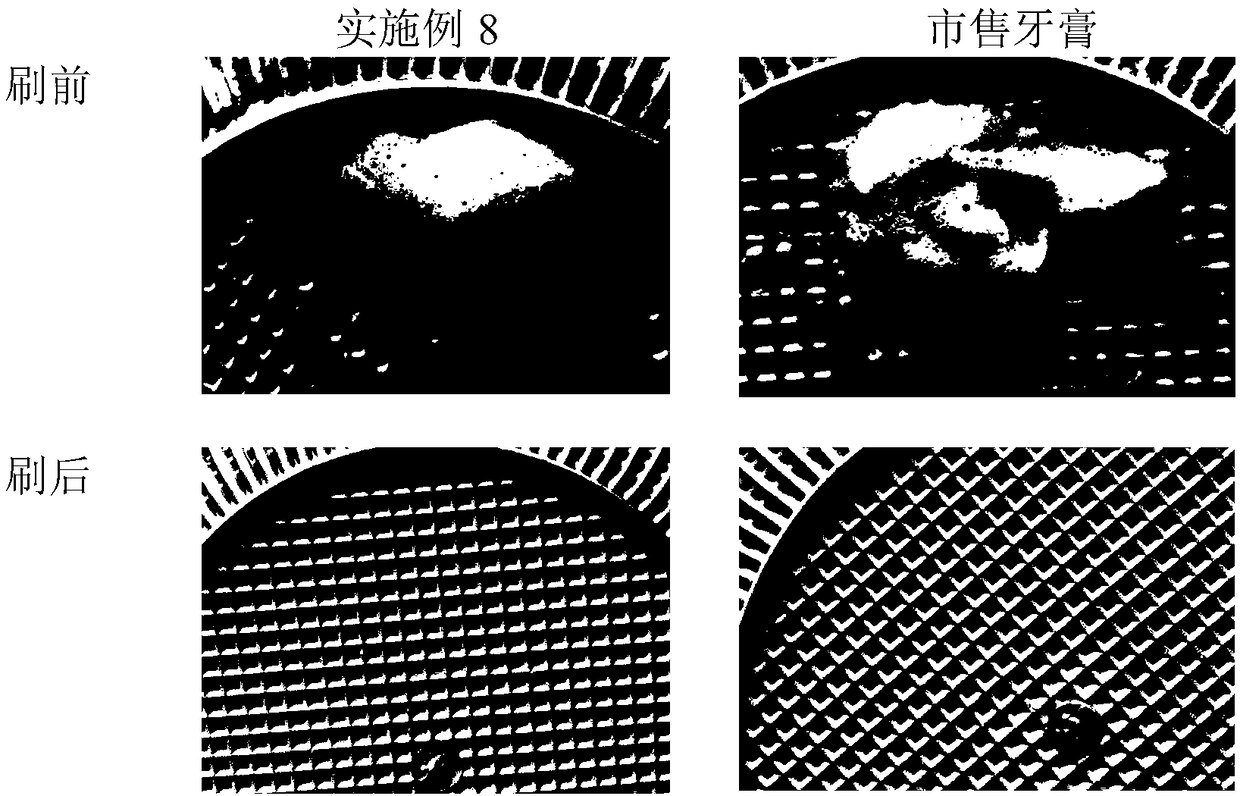

Embodiment 5-7

[0083] Toothpaste compositions were similarly prepared according to the method of Examples 1-4, and the component contents (weight %) and performance parameters of each product are shown in Table 2.

[0084] Table 2

[0085]

[0086] Note: " / " indicates that the viscosity is too high to be detected

[0087] result:

[0088] As shown in Table 2, when the content of calcium caseinate is less than 6% (such as 0.1%, 1% and 5%), the corresponding products have better foaming properties. But when the content of calcium caseinate is 6% or higher, the viscosity of the product is too large to be filled and detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com