Impedance matching Joseph Sen parametric amplifier, manufacturing method thereof and a communication module

A parametric amplifier and impedance matching technology, applied in the field of communication modules, impedance matching Josephson parametric amplifiers and their preparation, can solve the problems of large signal attenuation, large device size, etc., to ensure reliability, simplify the preparation process, and the device preparation process. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

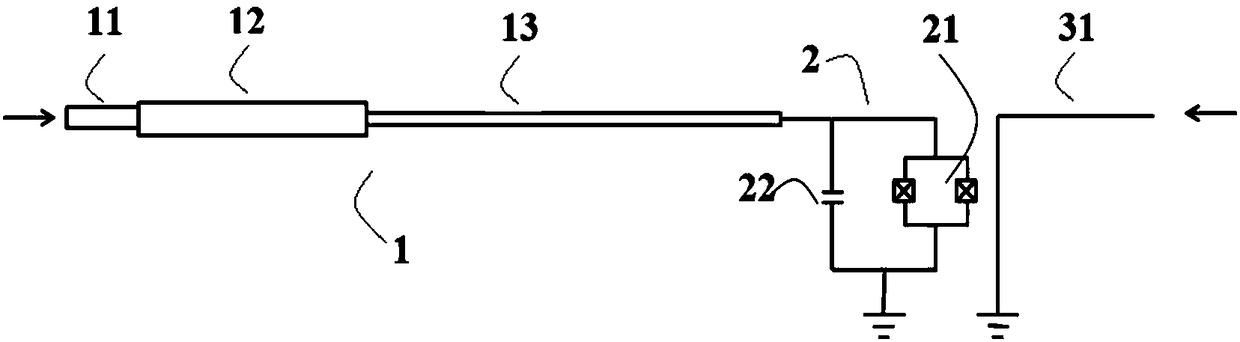

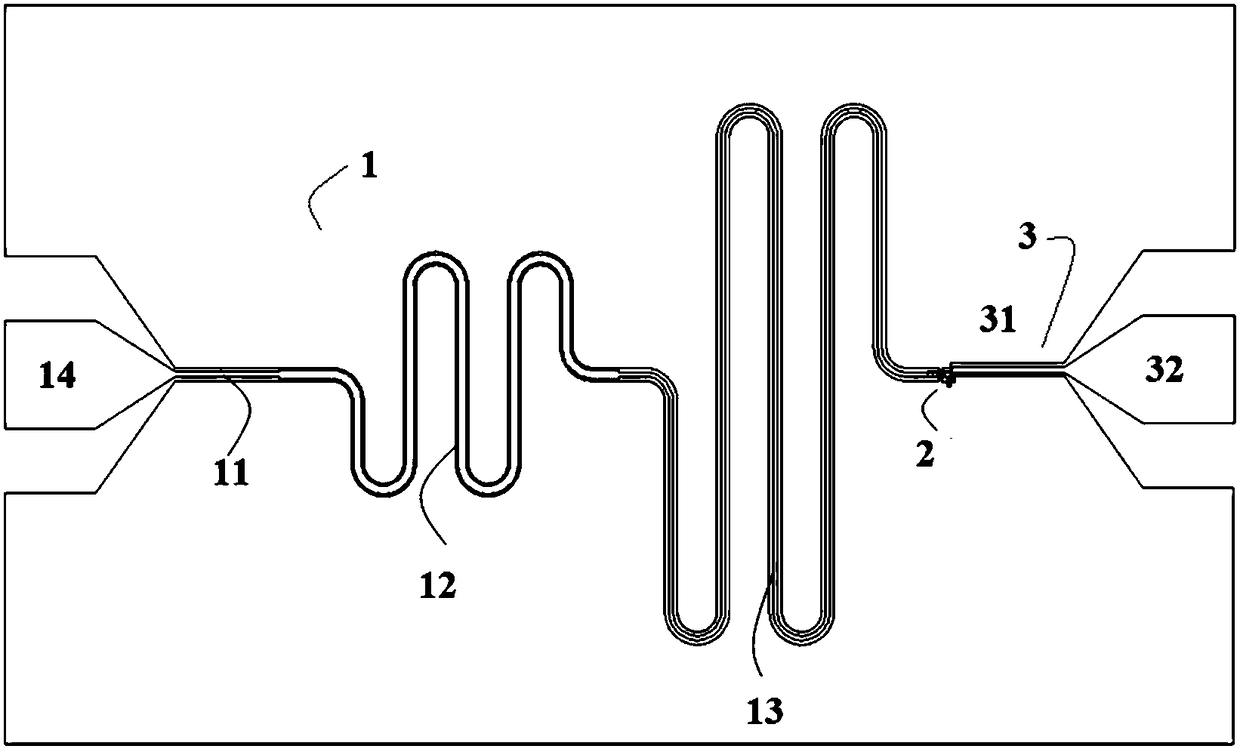

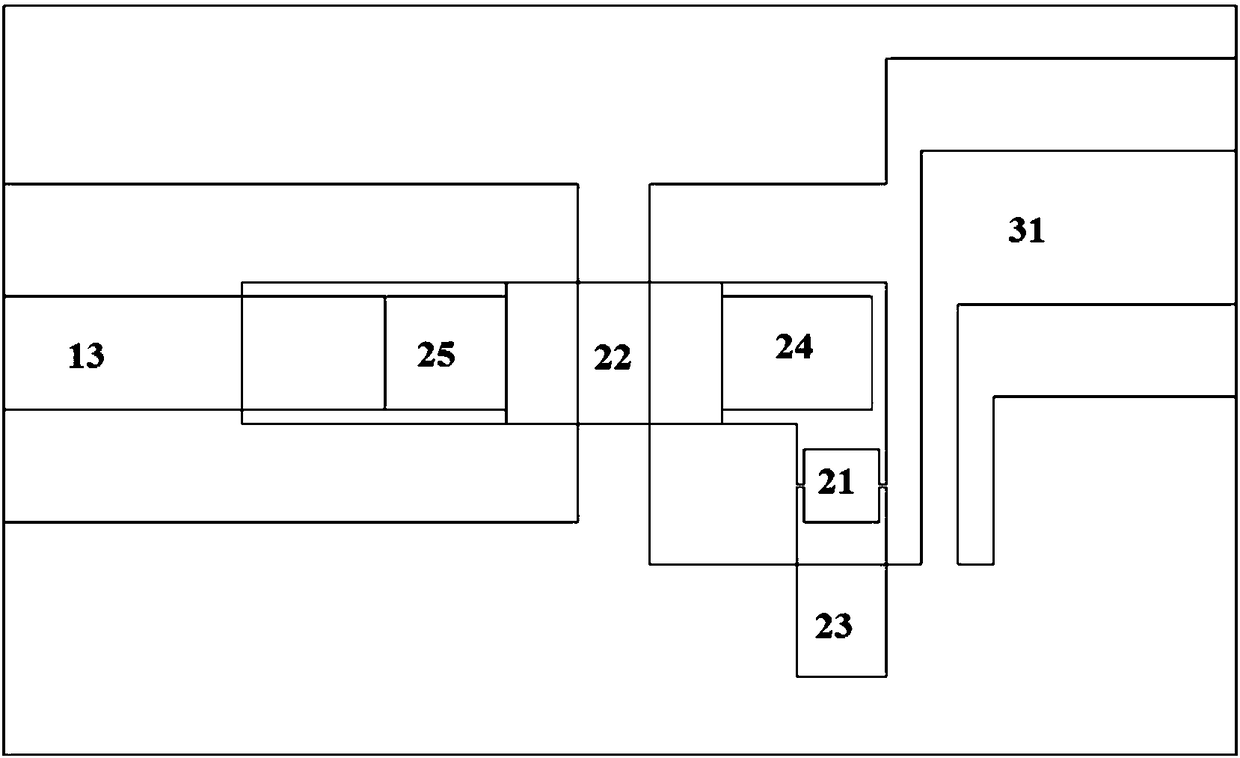

[0080] like figure 1 , figure 2 , image 3 As shown, an impedance matching Josephson parametric amplifier includes an impedance converter 1, an anharmonic resonant cavity 2 and a pumping microwave circuit 3, the first end of the impedance converter 1 is connected to the first signal input port 14, The second end of the impedance converter 1 is connected in series with the anharmonic resonant cavity 2, the first signal input port 14 is a microwave input port of a signal to be amplified, and the anharmonic resonant cavity 2 is connected to the The pumping microwave circuit 3 is a mutual inductance connection.

[0081]An impedance matching Josephson parametric amplifier, which includes an impedance converter 1, an anharmonic resonant cavity 2 and a pumping microwave circuit 3, the impedance converter 1 of the amplifier, the anharmonic resonant cavity 2 and the pumping microwave circuit 3 are all integrated in On the silicon substrate, the impedance converter 1 and the non-har...

Embodiment 2

[0101] The preparation method of the impedance matching Josephson parametric amplifier is as follows:

[0102] (1) The first coating, photolithography

[0103] a. Firstly, an aluminum film with a thickness of 30nm is plated on the cleaned substrate, and the aluminum film is coated by high-vacuum electron beam evaporation, and the coating rate is 0.1nm / s;

[0104] b. Use the ultraviolet lithography method to prepare the required graphics, the impedance converter 1, the first signal input port 14, the magnetic flux bias line 31, the second signal input port 32, the lower pole plate of the capacitor 22, and the ground plane are here Define in engraving, when the length L=9.07mm of signal microwave wavelength to be amplified, define the impedance of the first coplanar waveguide 11 as 50Ω, the impedance of the second coplanar waveguide 12 is 40Ω, the length of the second coplanar waveguide 12 is 0.25L, the impedance of the third coplanar waveguide 13 is 58Ω, the length of the thir...

Embodiment 3

[0126] The preparation method of the impedance matching Josephson parametric amplifier is as follows:

[0127] (1) The first coating, photolithography

[0128] a. First, plate an aluminum film with a thickness of 60nm on the cleaned substrate. The aluminum film is coated by high-vacuum electron beam evaporation, and the coating rate is 1nm / s;

[0129] b. Use the ultraviolet lithography method to prepare the required graphics, the impedance converter 1, the first signal input port 14, the magnetic flux bias line 31, the second signal input port 32, the lower pole plate of the capacitor 22, and the ground plane are here Define in engraving, when the length L=8.55mm of signal microwave wavelength to be amplified, define the impedance of the first coplanar waveguide 11 as 50Ω, the impedance of the second coplanar waveguide 12 is 40Ω, the length of the second coplanar waveguide 12 is 0.25L, the impedance of the third coplanar waveguide 13 is 58Ω, the length of the third coplanar w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com