Clean coal reversal combustion hot-blast stove with rib sheets

A hot blast stove and clean technology, which is applied in the direction of grate, combustion method, combustion equipment, etc., can solve the problems of hot air temperature not keeping up, low utilization rate of combustion-supporting air, thermal efficiency of explosive combustion and injury, and achieve social benefits of energy saving, environmental protection, Stable air output and comfortable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

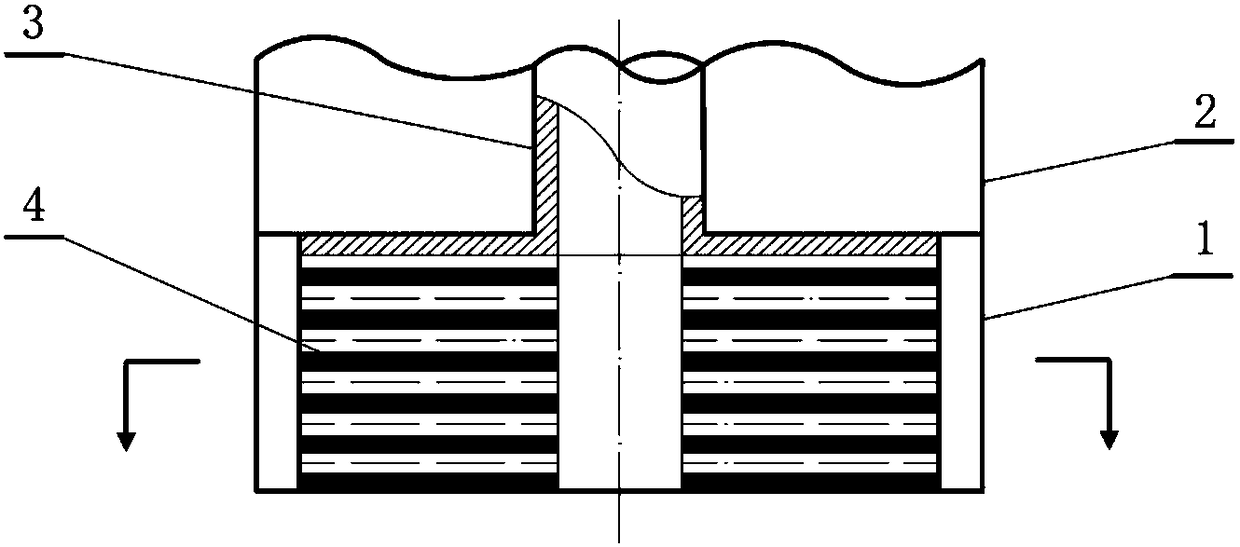

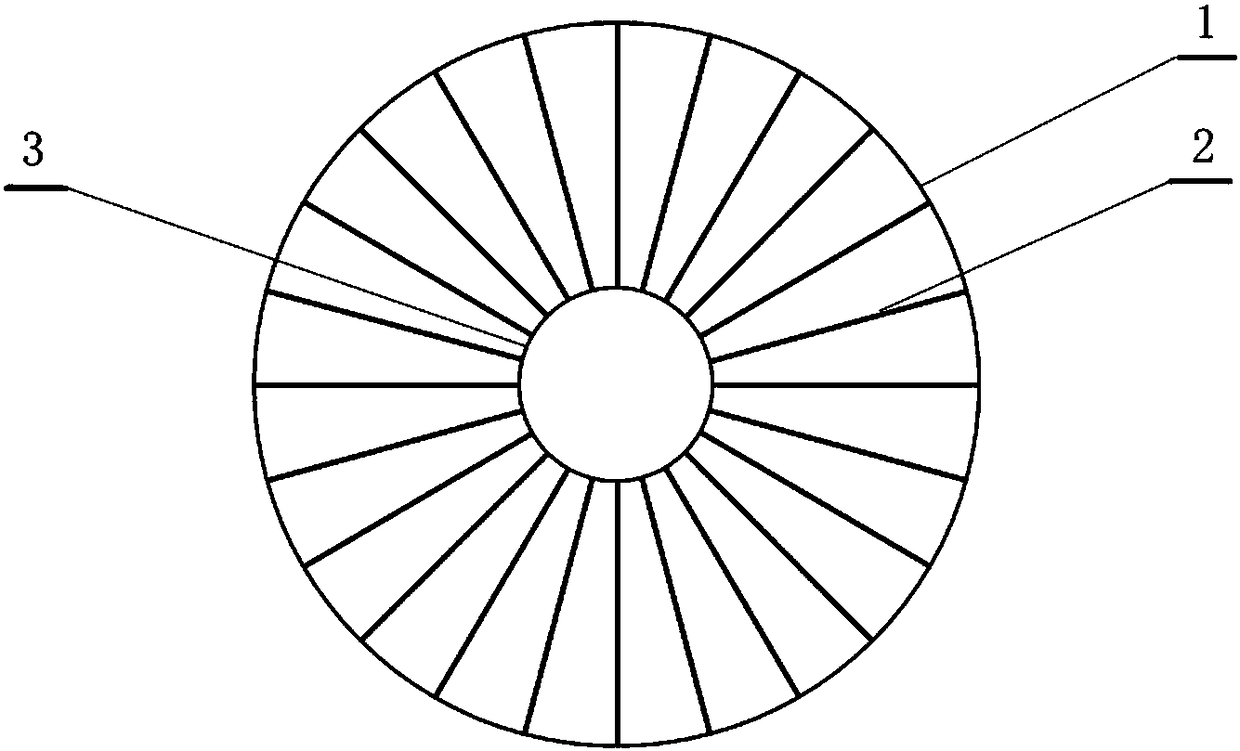

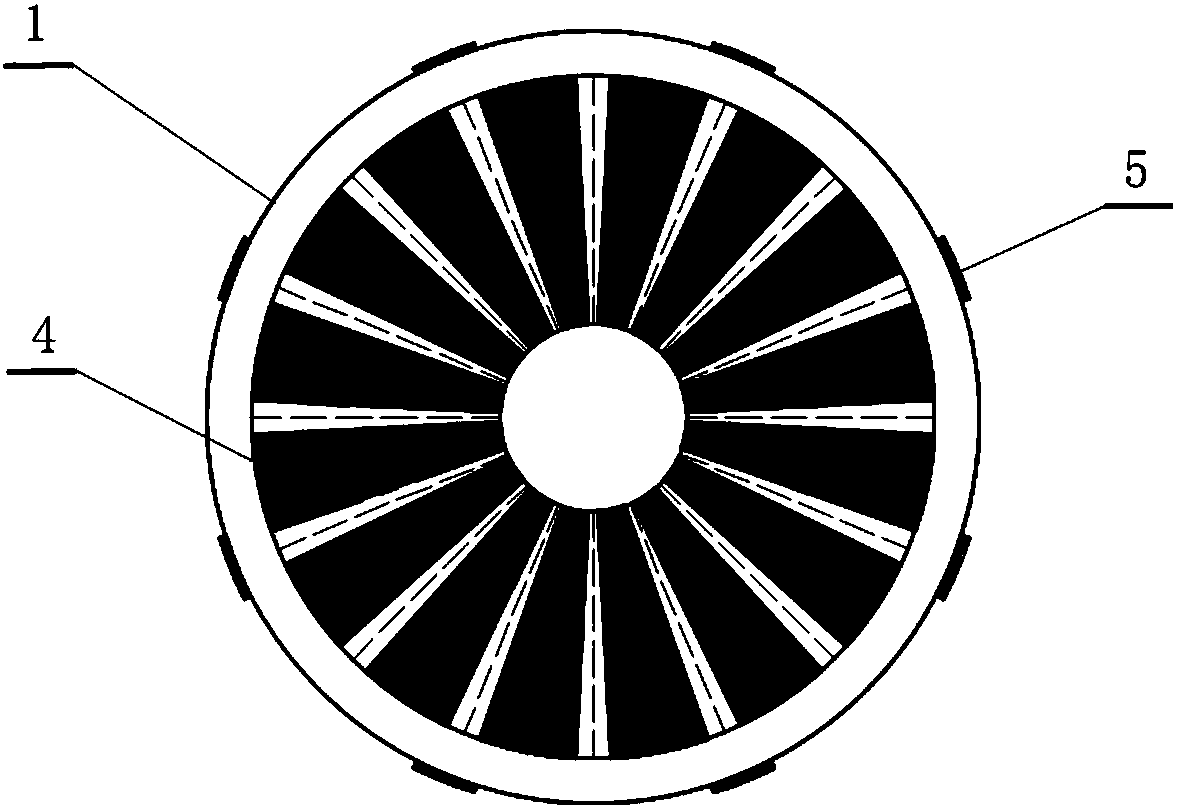

[0011] as attached figure 1 ~ attached image 3 As shown, the clean coal reverse-firing hot air stove with fins mainly includes a combustion chamber 1, fins 2, exhaust pipe 3 and coal bed 4.

[0012] The smoke exhaust pipe 3 is a vertically arranged corrosion-resistant metal round pipe. The outer wall of the smoke exhaust pipe 3 is fully welded and connected to many rectangular fins 2. The fins 2 are centered on the central axis of the smoke exhaust pipe 3 and radially distributed outwards in the radial direction. The thickness of the fins 2 is 0.1 mm to 1 mm. The inner vertical edge is on the outer wall of the smoke exhaust pipe 3 and parallel to the central axis of the smoke exhaust pipe 3, the outer vertical edge is on the upward extension surface of the side wall of the combustion chamber 1, and the bottom horizontal edge of the fin 2 is fully welded and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com