Vacuum tower for waste lubricating oil pretreatment

A technology of waste lubricating oil and decompression tower, which is used in lubricating oil distillation, processing of hydrocarbon oil, petroleum industry, etc., can solve the problems of decreased mass transfer and heat transfer efficiency, high temperature of waste oil at the outlet, and easy coking of tray equipment. To achieve the effect of reducing pressure drop, good separation effect and preventing coking blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

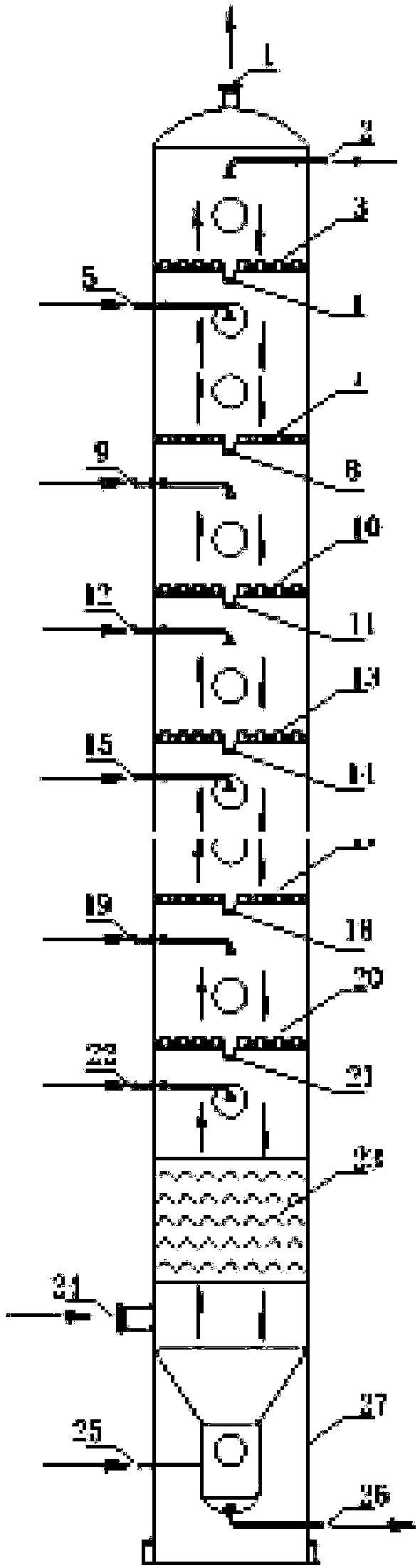

[0051] The structure of the present embodiment decompression tower is as figure 1 , in this embodiment, after the waste oil entering the feed port is vaporized, it passes through the over-vaporized oil production section, the distillate oil production section, and the diesel oil production section in sequence. In this embodiment, no filler is used, and the refined The distillation part and the rectification section only adopt the shower structure to carry out the rectification process.

[0052] The specific operation process is as follows:

[0053] The waste lubricating oil is heated in the heating furnace (the heating furnace is not shown), and the waste lubricating oil heated by the heating furnace enters the decompression tower through a mixer arranged between the heating furnace and the decompression tower.

[0054] Install the high-temperature mixer behind the heating furnace and on the pipeline before the vacuum tower feed, so that the raw material waste lubricating oil...

Embodiment 2

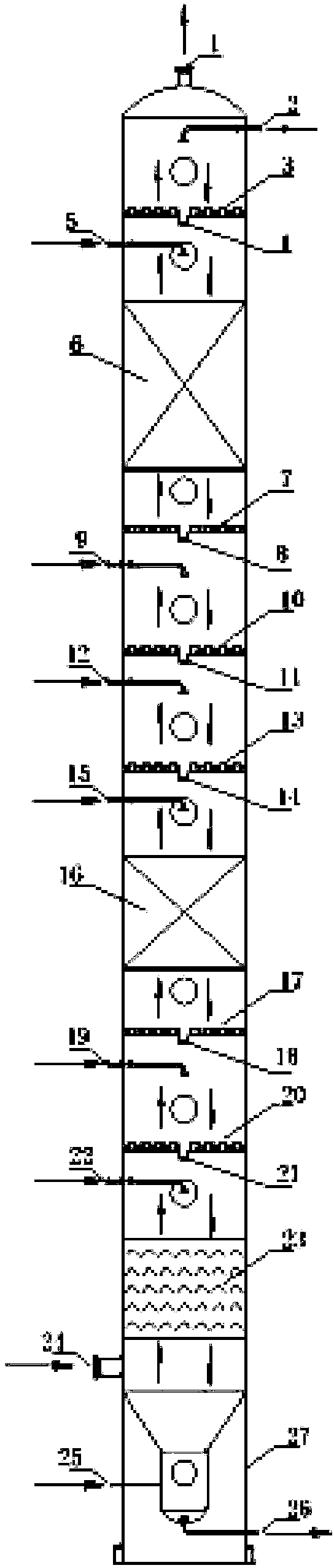

[0065] In this embodiment, after the waste oil entering the feed port is vaporized, it passes through the over-vaporized oil extraction section in sequence, and includes the first packing section, the distillate oil extraction section, the second packing section, and the diesel oil extraction section. . For details, please refer to figure 2 .

[0066] After setting the packing section, this embodiment still adopts the structure of 4 production sections (four side lines). In the structure of each extraction section, the over-vaporized oil extraction section includes an over-vaporized oil extraction port (21) and an over-evaporated oil return port (22), wherein the vaporized oil extraction port (21) is connected to an oil collection tank. And, wherein the diesel oil extraction section includes a first middle section, and the distillate oil extraction section includes a second middle section, a third middle section and a fourth middle section; each of the above four middle sec...

Embodiment 3

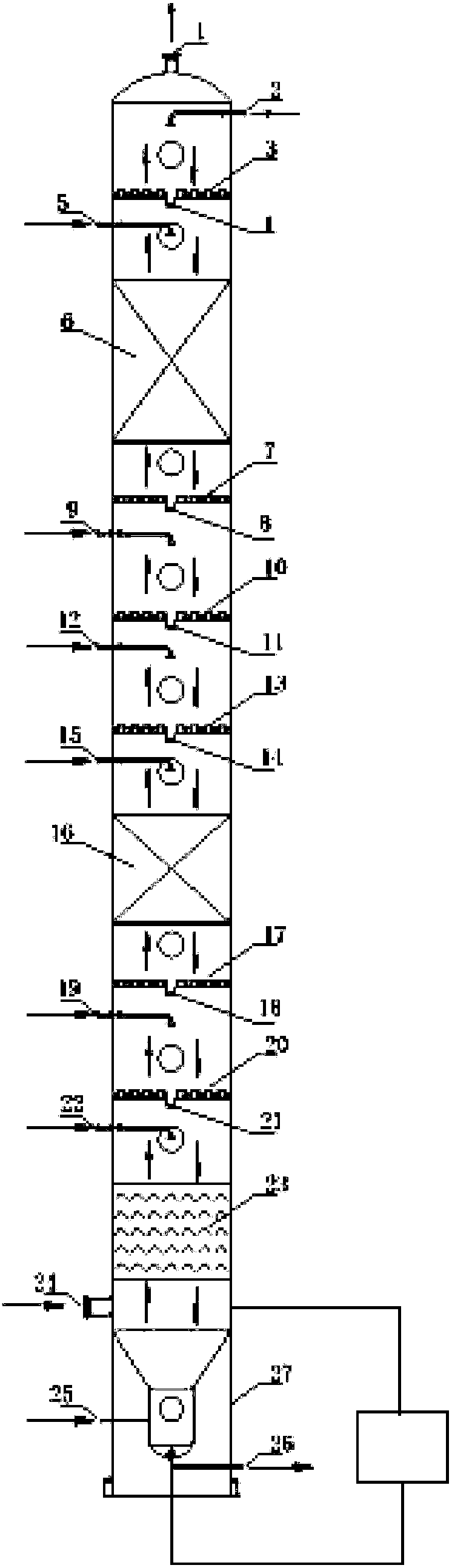

[0071] In this embodiment, after the waste oil entering the feed port is vaporized, it sequentially passes through the overvaporized oil extraction section, the first packing section, the distillate oil extraction section, the second packing section, and the diesel oil extraction section. The feature of this embodiment is that a tower bottom reboiler (using an electric heater structure) is provided to speed up the vaporization of waste lubricating oil, which sends a part of the tower bottom oil directly to the vicinity of the baffle after boiling to speed up vaporization.

[0072] The specific operating process is similar to that of Embodiments 1 and 2, so there is no need to repeat them here.

[0073] Here, the present invention firstly finds in the pretreatment and refining process of waste lubricating oil that high vacuum and low pressure drop are adopted in the decompression tower, and six sets of specially designed reflux liquid sprayers are arranged to fully disperse the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com