Fuel oil burner for incinerator

A technology of burners and incinerators, which is applied in the direction of burners, lighting and heating equipment, etc. It can solve the problems of high ignition failure rate, expensive imported burners, and easy burnout of diffuser disc components, so as to save costs and ensure service life , Solve the effect that the oil nozzle is easy to coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

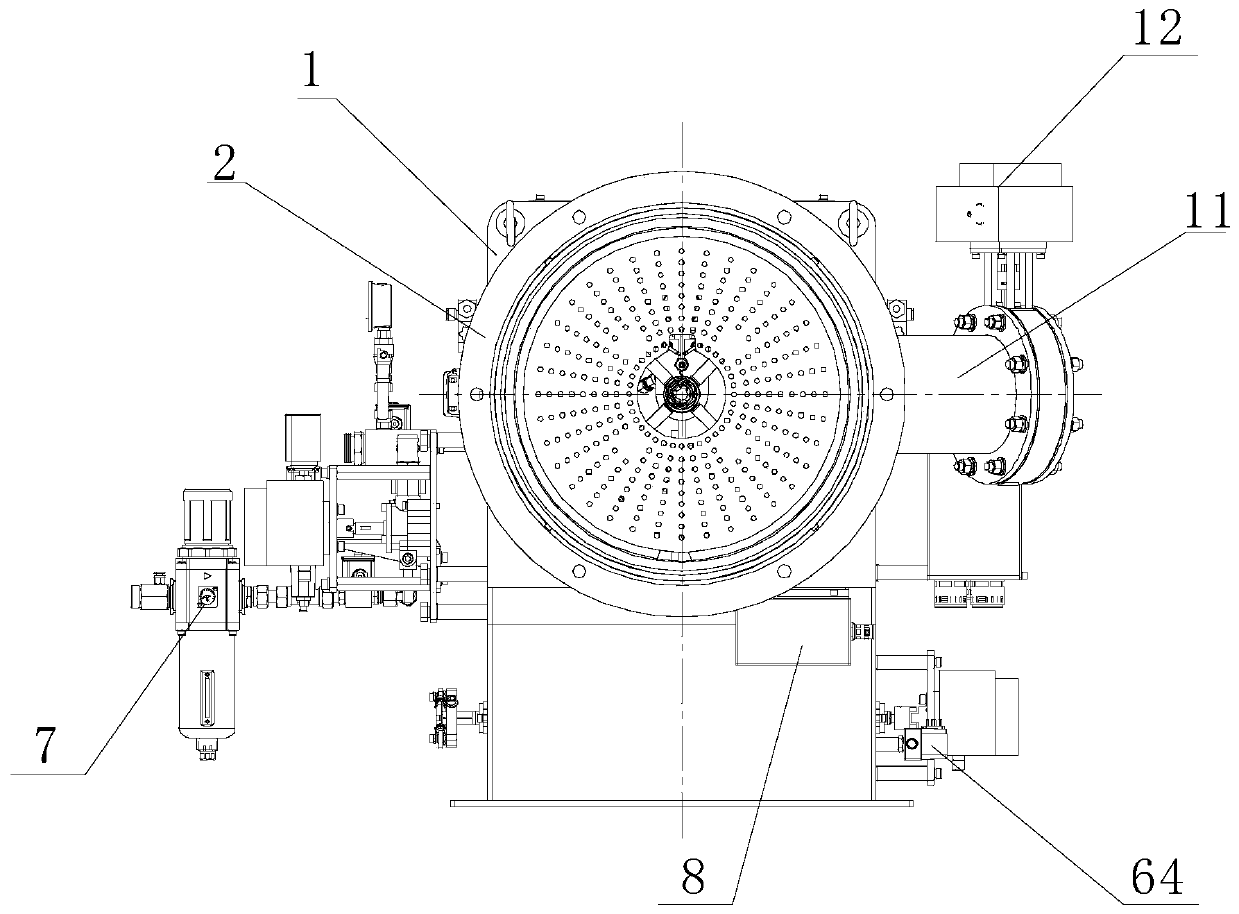

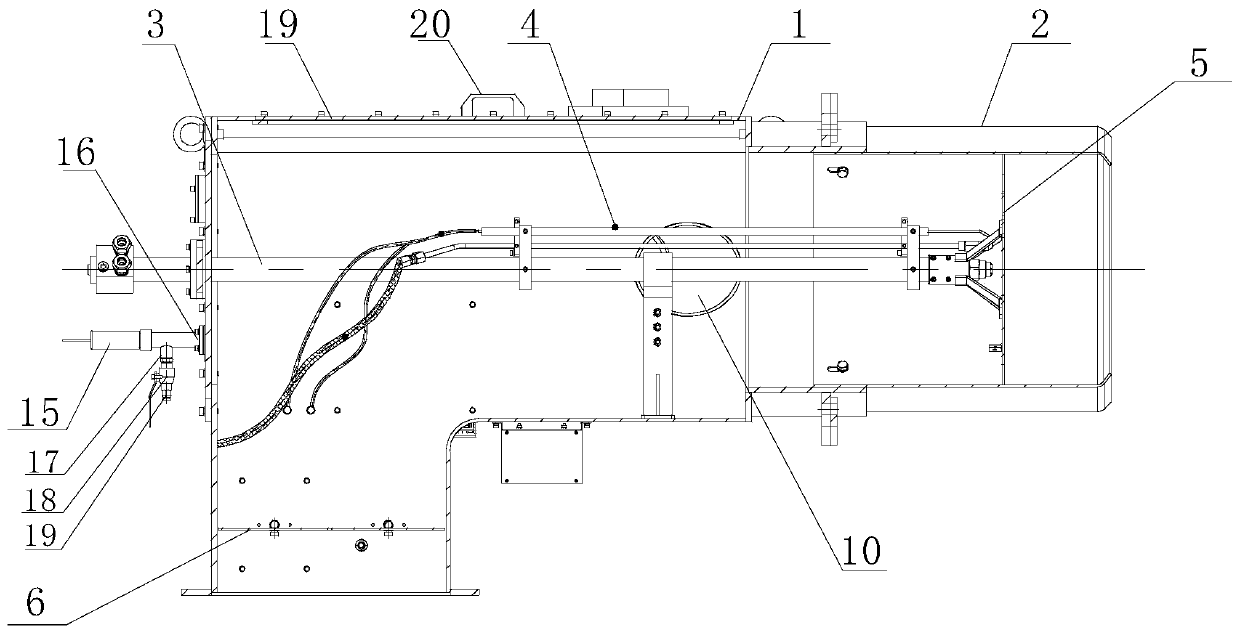

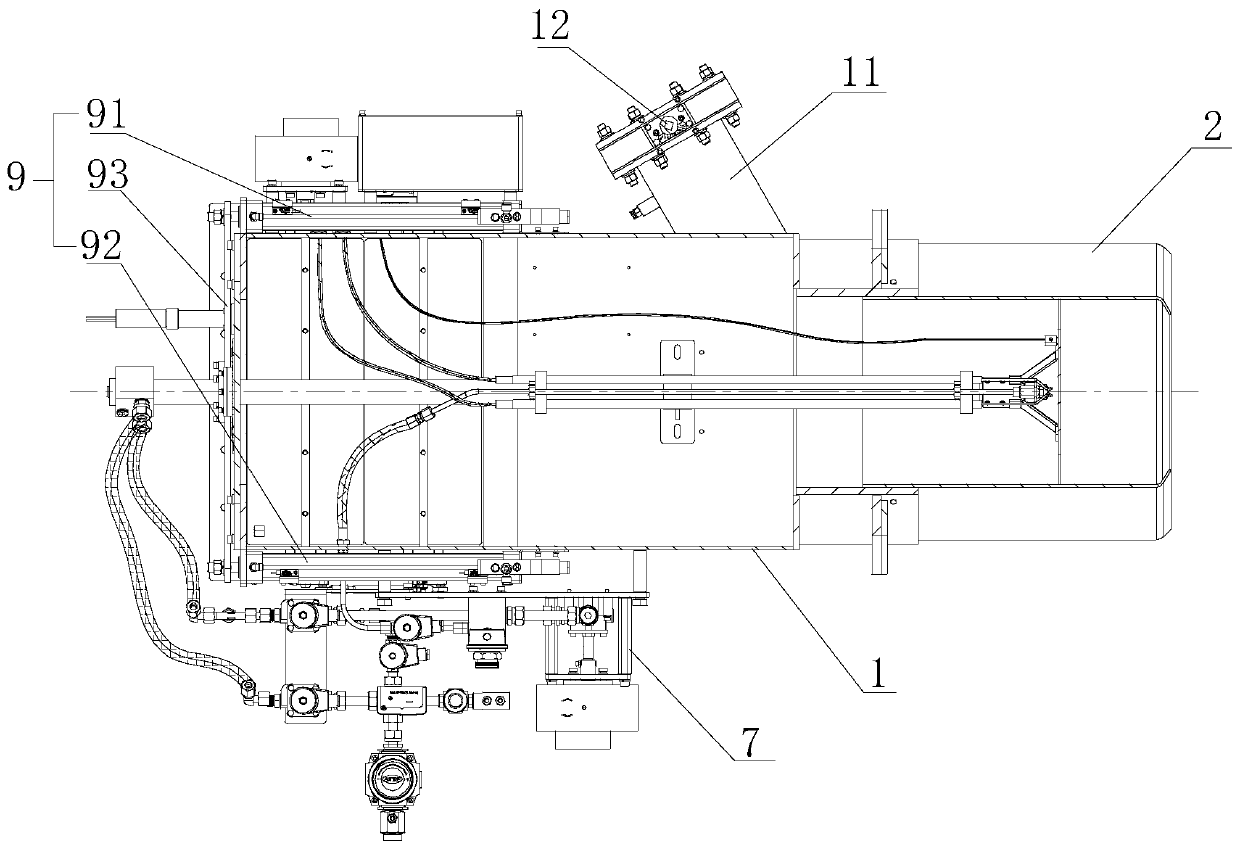

[0032] Such as Figure 1-5 As shown, an oil burner for an incinerator includes a burner housing 1, a flame tube 2, an oil gun assembly 3, an ignition needle assembly 4, a diffusion disc 5, a damper adjustment mechanism 6, an oil circuit module 7, The ignition transformer 8, the flame cylinder 2 are arranged at the front end of the burner housing 1, the diffuser plate 5 is arranged in the flame cylinder 2, the oil gun assembly 3 is arranged at the center of the inner chamber of the burner housing 1, and its front end extends to At the diffuser plate 5, the ignition needle assembly 4 is installed on the oil gun assembly 3, and its front end extends to the diffuser plate 5, the damper adjustment mechanism 6 is arranged at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com