Polyester molding composition, preparation method and applications thereof

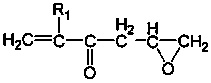

A molding composition and polyester technology, applied in the field of polyester molding composition and its preparation, can solve the problems of high molding shrinkage, inability to carry out LDS process, low bonding force between LDS material and metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11 and comparative example 1-3

[0079] a. Blend the polyester resin and the impact modifier in a high-speed mixer for 5min-30min according to the ratio in Table 1 to prepare a premix;

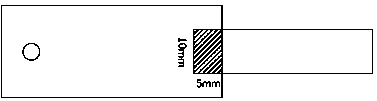

[0080] b. Blend the premix obtained in step a, laser-sensitive additives, and other additives in a high-speed mixer for 5min-10min to obtain a blend, and then feed the blend into a twin-screw extruder, reinforcing materials and / or Or the filler adopts side feeding, melt extrusion, cooling, and granulation, and the temperature of the twin-screw extruder is 180-320°C, the screw speed is 60 rpm-1200rpm, and the feeding amount is 20 kg / h-2000kg / h, the gauge pressure of the vacuum pump is -0.05 MPa~-0.12MPa.

[0081] in,

Embodiment 1

[0082] Example 1: In step a, the blending time is 15 minutes. In step b, the temperature of the twin-screw extruder is 200°C-300°C, the screw speed is 350rpm, the feed rate is 500kg / h, and the gauge pressure of the vacuum pump is -0.08 MPa.

Embodiment 2

[0083] Example 2: In step a, the blending time is 10 minutes. In step b, the temperature of the twin-screw extruder is 180°C-320°C, the screw speed is 100rpm, the feed rate is 1100kg / h, and the gauge pressure of the vacuum pump is -0.05 MPa, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com