Polyurethane stock solution for cement baffle as well as preparation method and application of polyurethane stock solution

A polyurethane and baffle technology, which is applied to the polyurethane stock solution for cement baffles and its preparation and application fields, can solve the problems of low density of the rubber surface, affecting the next use, water slurry infiltrating into the baffles, etc. The effect of prolonging service life and reducing inner core density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

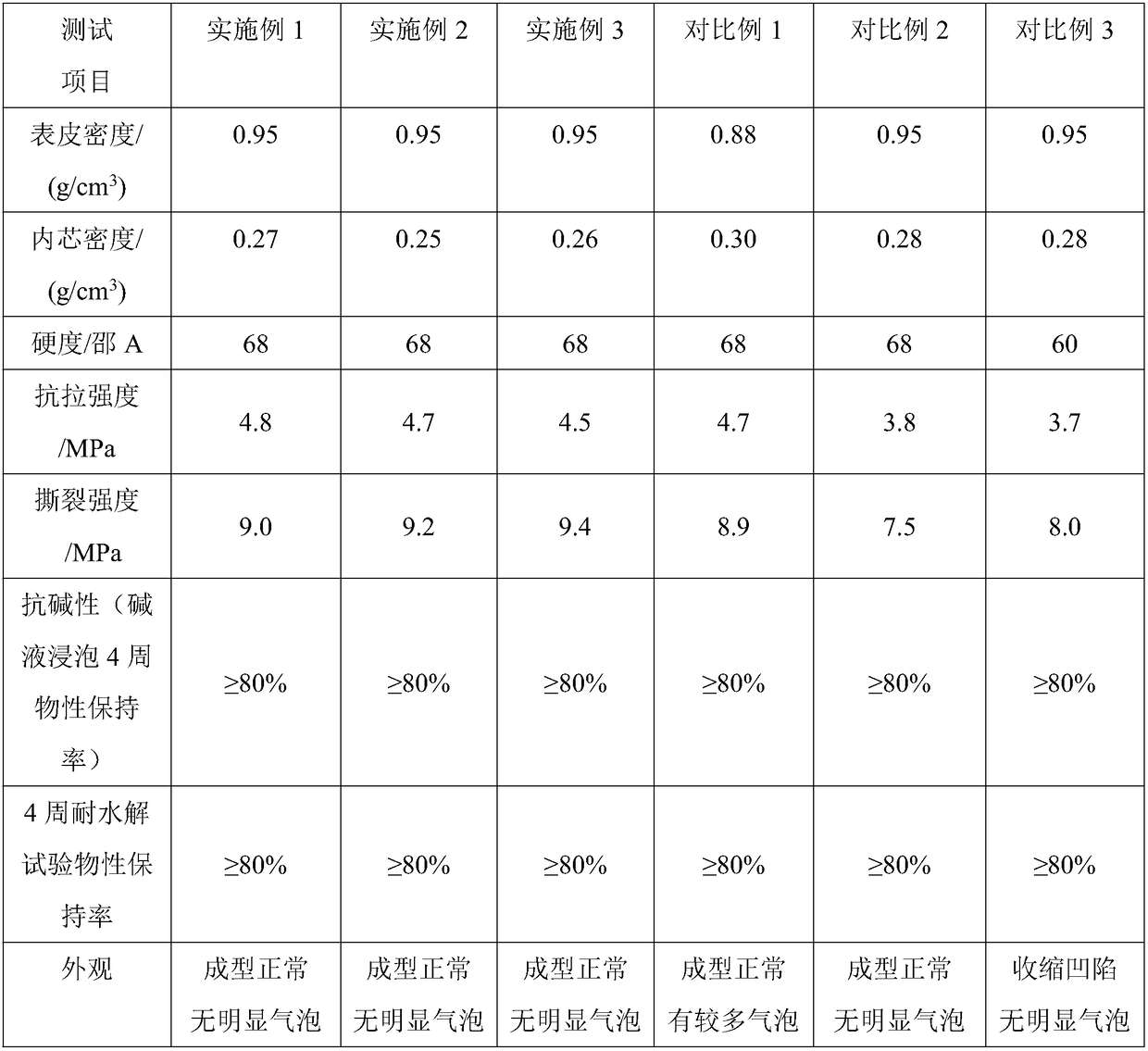

Examples

Embodiment 1

[0044] Control the moisture content of polyether polyols, polymer polyols, chain extenders, catalysts, foam stabilizers, physical foaming agents, flame retardants and cell openers below 0.05%;

[0045] The polyoxypropylene diol (oxygen content is 15%, number-average molecular weight 5000) of the ethylene oxide capping of 60.0kg, the polymer polyol of 40.0kg (functionality is 3, and solid content is 30%, Hydroxyl value is 19mgKOH / g), 4.17kg of ethylene glycol, 0.83kg of 1,4-butanediol, the reaction product of 0.45kg of diethyl sulfate and triethylenediamine, 0.05kg of 70% bis(di Methylaminoethyl) ether solution, 0.5kg of organosilicon foam stabilizer, 10.0kg of pentafluoropropane (HFC-245fa), 0.10kg of water, 5.0kg of dimethyl phosphate, 1.0kg of ethylene oxide Alkane-terminated polyoxypropylene glycol (70% ethylene oxide content, 31 mgKOH / g hydroxyl value) was put into a reaction kettle, mixed at 35°C for 4 hours, discharged, and stored to obtain component A of polyurethane st...

Embodiment 2

[0050]Control the moisture content of polyether polyol, polymer polyol, chain extender, catalyst, foam stabilizer, physical foaming agent, flame retardant and cell opening agent to be controlled below 0.05%, and 90.0kg of ethylene oxide End-capped polyoxypropylene diol (ethylene oxide content is 20%, number average molecular weight 8000), 10.0kg polymer polyol (functionality is 3, solid content is 45%, hydroxyl value 25mgKOH / g), 13.33kg of ethylene glycol, 1.67kg of 1,4-butanediol, the reaction product of 1.67kg of diethyl sulfate and triethylenediamine, 0.33kg of 70% bis(dimethylaminoethyl) ether solution, 2.0kg of silicone foam stabilizer, 15.0kg of pentafluoropropane (HFC-245fa), 1.00kg of water, 10.0kg of dimethyl methyl phosphate, 3.0kg of ethylene oxide-capped polyoxypropylene glycol (The content of ethylene oxide is 70%, and the hydroxyl value is 35mgKOH / g) is put into the reaction kettle, mixed at 45° C. for 3 hours, discharged and stored to obtain component A of the p...

Embodiment 3

[0054] Control the moisture content of polyether polyol, polymer polyol, chain extender, catalyst, foam stabilizer, physical foaming agent, flame retardant and cell opening agent to be controlled below 0.05%, and 75.0kg of ethylene oxide End-capped polyoxypropylene diol (ethylene oxide content is 25%, number average molecular weight 6000), 25.0kg polymer polyol (functionality is 2, solid content is 30%, hydroxyl value 15mgKOH / g), 8.57kg of ethylene glycol, 1.43kg of 1,4-butanediol, the reaction product of 0.80kg of diethyl sulfate and triethylenediamine, 0.10kg of 70% bis(dimethylaminoethyl) ether solution, 1.0kg of silicone foam stabilizer, 12.0kg of pentafluoropropane (HFC-245fa), 0.50kg of water, 8.0kg of dimethyl phosphate, 2.0kg of ethylene oxide-capped polyoxypropylene glycol (The content of ethylene oxide is 80%, and the hydroxyl value is 31mgKOH / g) into the reaction kettle, after mixing at 45°C for 3 hours, discharge and store to obtain component A of the polyurethane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com