Treatment technology of browned waste liquid produced by PCB (Printed Circuit Board)

A PCB circuit board and processing technology technology, which is applied to the processing technology field of browning waste liquid produced by printed PCB circuit boards, can solve the problems of low copper recovery rate, unsatisfactory effect of electrolytic browning waste liquid, insufficient energy saving and environmental protection, etc. , to achieve the effect of reducing pollutant indicators, good application prospects and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

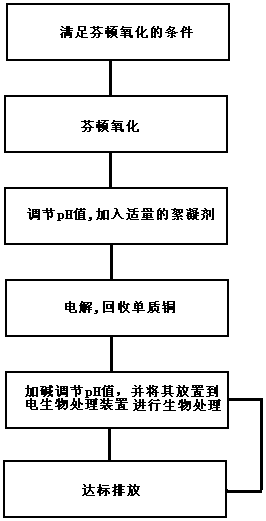

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 Shown, the processing technology of browning waste liquid produced by printed PCB circuit board of the present invention comprises the following steps,

[0034] Step (A), adding 0.6-1g of ferrous sulfate in every liter of browning waste liquid, satisfying the condition of Fenton oxidation;

[0035] Step (B), performing Fenton oxidation on the browning waste liquid to oxidize and degrade the complexed copper in the browning waste liquid, and transform the complexed copper into ionic copper;

[0036] In step (C), the pH value of the browning waste liquid after the Fenton oxidation reaction is between 2.0-2.5, and the pH value is adjusted to 4.5-5.5 by adding alkali; at the same time, an appropriate amount of flocculants PFS and PAM are added, wherein each liter of browning waste liquid The amount of flocculant PFS added to waste liquid is 0.8g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com