Metal resin composite material grinding wheel special for steel rail grinding and manufacturing method thereof

A technology of metal resin and composite materials, which is applied in the field of grinding wheels, can solve the problems of low rail material removal efficiency, fast consumption of grinding edges, and short service life of grinding wheels, so as to reduce burn bluing, reduce grinding heat, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

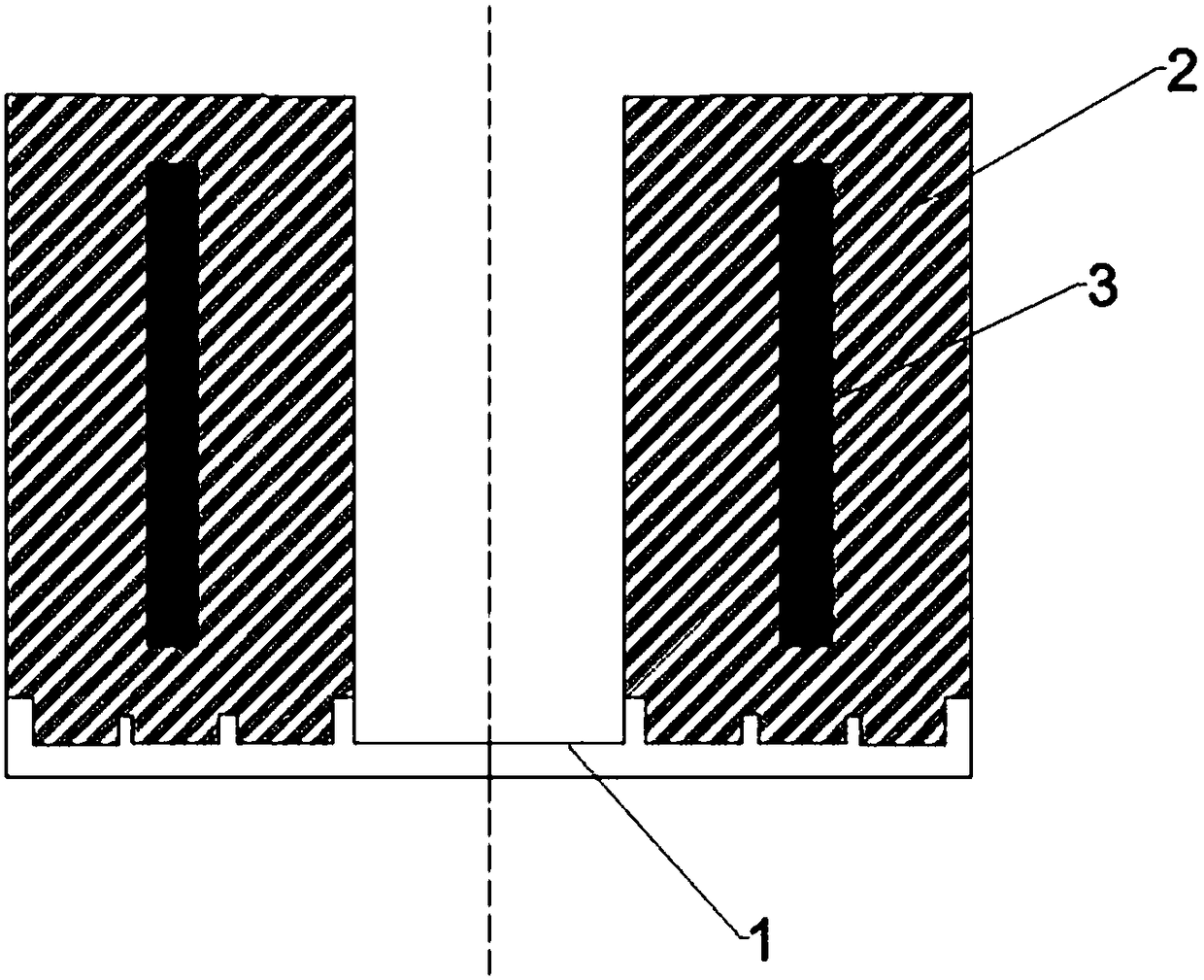

Embodiment 1

[0040] Weigh the CBN abrasive with a mass ratio of 40%, and the abrasive concentration is 0.88g / cm 3, the mass proportion is 55% Cu-Sn-Ti alloy solder powder, the mass proportion is 5% HBN powder, and 3% liquid paraffin forming agent of the total mass of the mixture is added. The brazed CBN sintered block 3 was prepared according to the above steps. Brazed CBN grinding block 3 has a bottom surface radius of 5mm and a height of 50mm.

[0041] Then select the phenolic resin binder and the zirconium corundum abrasive to mix, and the mass ratio of the modified phenolic resin is 18%; the particle size is selected to be 14-16 mesh zirconium corundum as the abrasive, and the mass ratio is 82%, and the zirconium corundum abrasive is uniformly wetted with furfural first, and then Then add a resin bond, mix the materials, and mix evenly to prepare the resin bond zirconium corundum abrasive 4.

[0042] There are 12 brazing CBN sintered blocks 3, which are distributed equiangularly over...

Embodiment 2

[0044] Weigh the CBN abrasive with a mass ratio of 30%, and the abrasive concentration is 0.66g / cm 3 , the mass proportion of Cu-Sn-Ti alloy solder powder is 62.5%, and the mass proportion of HBN powder is 7.5%. And add 3% liquid paraffin forming agent of the total mass of the mixture. The brazed CBN sintered block 3 was prepared according to the above steps. Brazed CBN grinding block has a bottom radius of 5mm and a height of 50mm.

[0045] Then choose modified phenolic resin (phenolic resin binder) and zirconium corundum abrasive to mix, the mass ratio of modified phenolic resin is 22%; choose zirconium corundum with a particle size of 14-16 mesh as the abrasive, and the mass ratio is 78, first use furfural to evenly wet Zirconium corundum abrasive, and then add a resin bond, mix the materials, mix evenly, and prepare the resin bond zirconium corundum abrasive 4.

[0046] There are 12 brazed CBN sintered blocks 3, which are equiangularly distributed over the entire circum...

Embodiment 3

[0048] Weigh the mass of CBN abrasive as 40%, and the abrasive concentration is 0.88g / cm 3 , the mass proportion of Cu-Sn-Ti alloy solder powder is 55%, and the mass proportion of HBN powder is 5%. And add 3% liquid paraffin forming agent of the total mass of the mixture. The brazed CBN sintered block 3 was prepared according to the above steps. The brazed CBN grinding block has a bottom radius of 10mm and a height of 70mm.

[0049] Then choose modified phenolic resin (phenolic resin binder) and zirconium corundum abrasive to mix, the mass ratio of modified phenolic resin is 20%; choose zirconium corundum with a particle size of 14-16 mesh as abrasive, and the mass ratio is 80%, first use furfural to uniform Wet the zirconium corundum abrasive, and then add the resin bond, mix the materials, mix evenly, and prepare the resin bond zirconium corundum abrasive 4.

[0050] There are 24 brazing CBN sintered blocks 3, which are distributed equiangularly over the entire circumfere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com