Overall waveform piece machining technology for automobile clutch

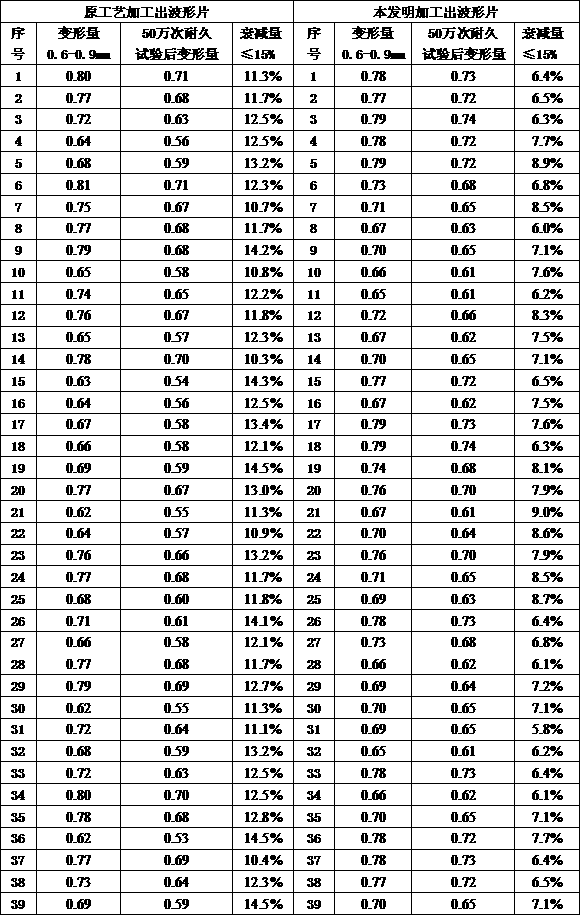

A processing technology and corrugated sheet technology, applied in the field of clutch processing, can solve the problems of heavy workload, automobile jitter, inconsistent steel belt fiber direction, etc., and achieve the effect of reducing fatigue attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

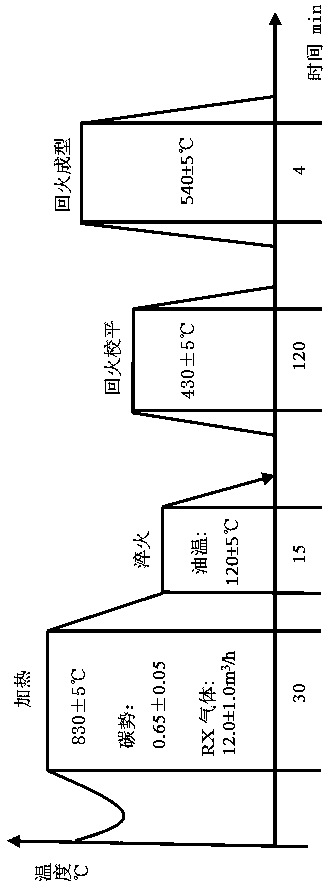

[0017] The steps of the present invention are:

[0018] (1) Prepare 65Mn steel strip in spheroidizing annealed state, width 226mm, thickness 0.80mm, hardness 100-130HV 30 .

[0019] (2) Stamping processing flat material, using conventional stamping method for material processing, the process is punching - punching groove - punching center hole - blanking; the place that is different from the original process is the last sequence of blanking No molding of the integral corrugated sheet is required. The blanking will be described in detail below.

[0020] (3) Overall corrugated sheet quenching:

[0021] a. Loading and cleaning: Put the punched workpieces on the load beam evenly at intervals of 500 pieces per furnace to ensure that the blanking direction of the workpieces is in the same direction, put the loaded beams on the heating fixture, and use a conveying vehicle Send the heating jig full of workpieces to the cleaning station, open the front door of the washing machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com