Washing machine motor detection method and washing machine

A detection method and washing machine technology, which are applied to other washing machines, washing machine control devices, washing devices, etc., can solve the problems of differences in the magnetization amount of variable frequency DDM motors, affecting the energy consumption of the whole machine, and reducing the use efficiency, so as to achieve energy consumption and Use Efficiency Consistent Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Before the washing machine leaves the factory, it will carry out inspections such as empty bucket washing and empty bucket dehydration. The method provided in this example can be applied at this stage to avoid noise or abnormal sound after the washing machine leaves the factory due to motor problems, so that maintenance personnel can quickly troubleshoot the noise. or abnormal sound.

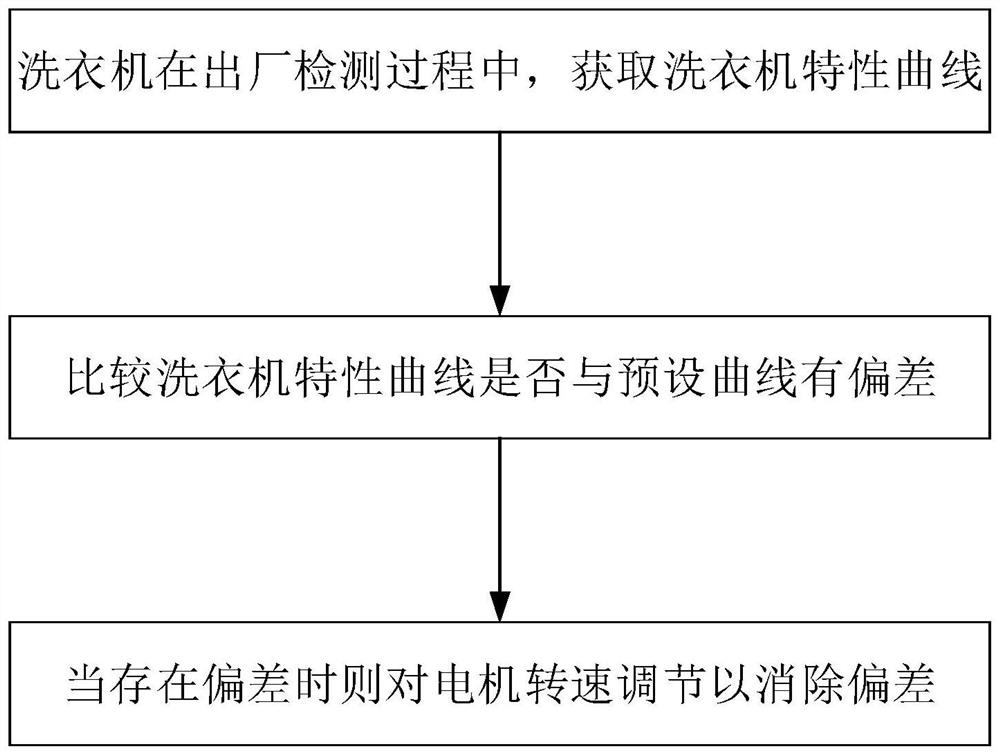

[0028] Such as figure 1 As shown, this embodiment provides a washing machine motor detection method, the method first obtains the washing machine characteristic curve in the washing machine factory inspection process, and then compares whether the washing machine characteristic curve deviates from the preset curve, and if there is a deviation, then the The motor speed is adjusted to eliminate the deviation.

[0029] In the present invention, testing is carried out before the washing machine leaves the factory, and when there is a deviation between the obtained washing machine characteris...

Embodiment 2

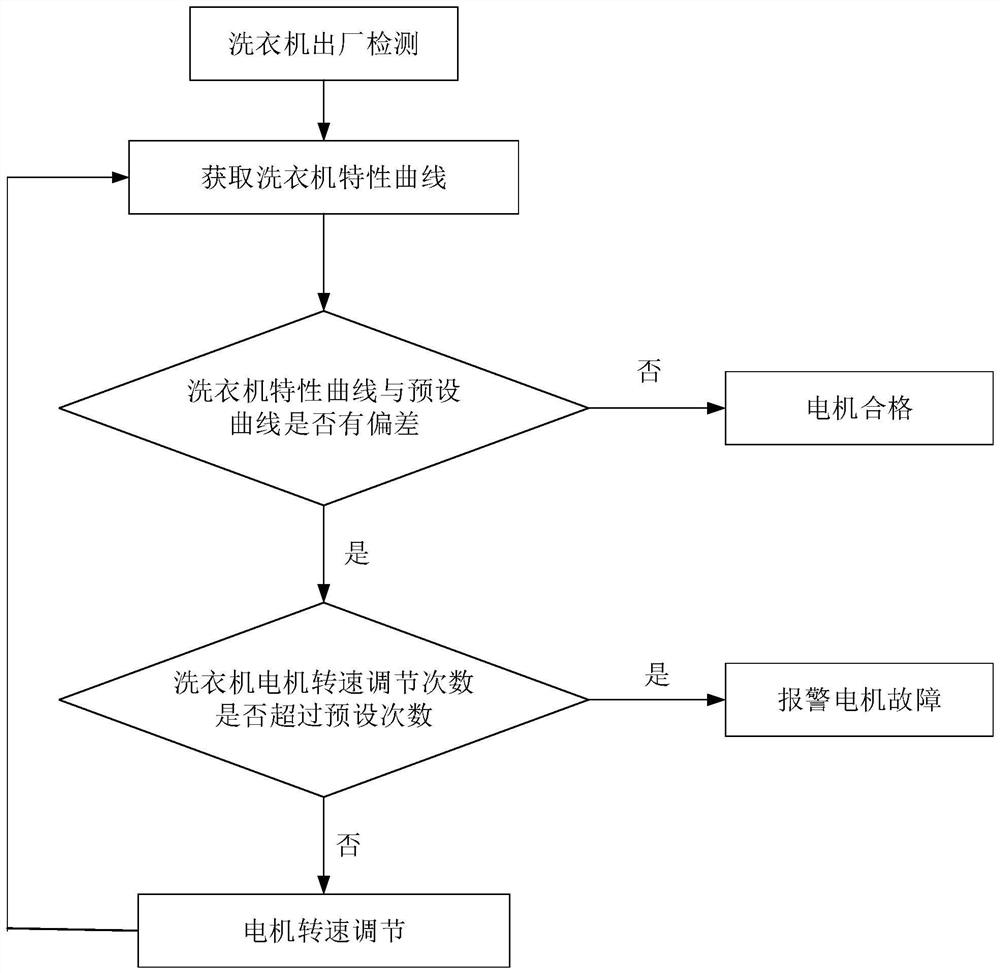

[0035] Such as figure 2 As shown, this embodiment provides a washing machine motor detection method. On the basis of Embodiment 1, it further limits the multiple motor speed adjustments to the washing machine characteristic curve. After each speed adjustment, the motor speed after adjustment The characteristic curve of the washing machine is compared with the preset curve. When the number of adjustments of the motor speed of the washing machine does not exceed the preset number of times, the new washing machine characteristic curve obtained after the motor speed adjustment can be compared with the preset curve, which avoids the motor speed value selected during the motor speed adjustment being within the preset range. , but when the motor speed value is too large or too small when the deviation is caused, it will directly prompt the operator of the motor failure, so as to avoid increasing the workload of the operator.

[0036] More specifically, if the characteristic curve o...

Embodiment 3

[0040] This embodiment provides a washing machine, and the motor used in the washing machine is tested at the factory using the above-mentioned detection method for the washing machine motor.

[0041] The washing machine of the present invention, by using the above method, can make the washing machine detect the characteristic curve of the motor when it leaves the factory, and make the characteristic curve of the motor consistent after the weighting process, so that the washing machine will not be affected by the presence of the motor in the working process after leaving the factory. Abnormal sound or noise due to deviation, to ensure that the energy consumption and use efficiency of each washing machine leaving the factory are consistent, and after the washing machine leaves the factory, the maintenance personnel can quickly check the cause of the abnormal sound during the maintenance process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com