Composite frame cladding cover for long-life tundish

A composite frame and tundish technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of cracking and peeling of refractory materials, low service life of cover, and increase of production cost, so as to reduce thermal stress, Good ability to resist molten steel erosion and reduce the cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

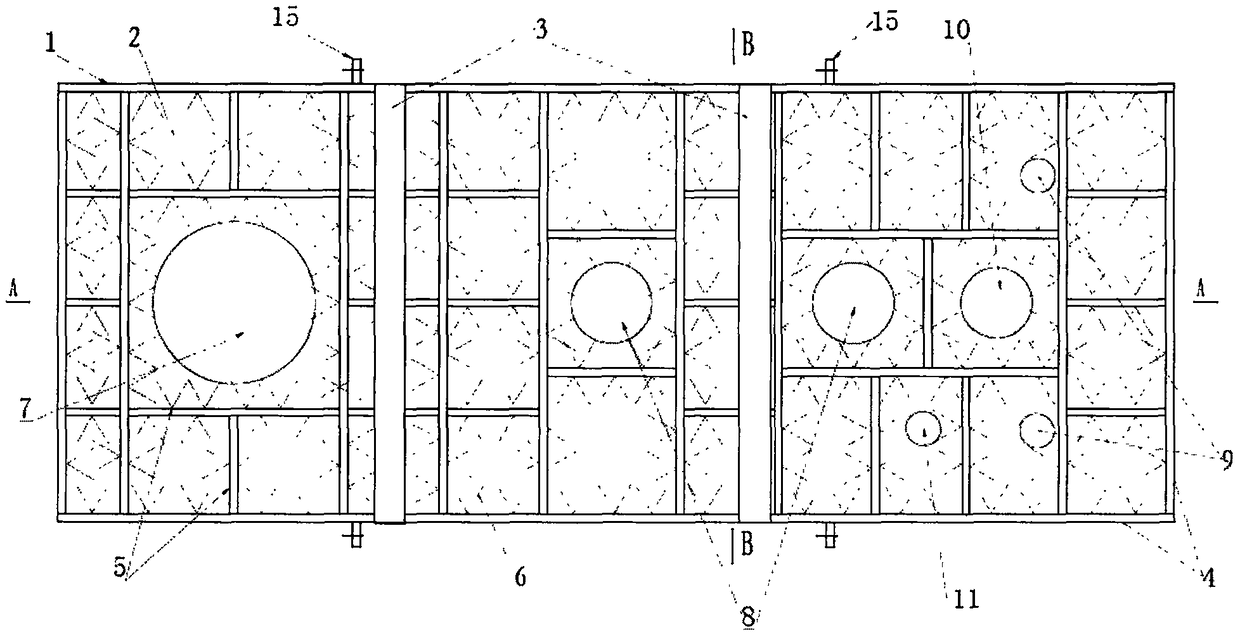

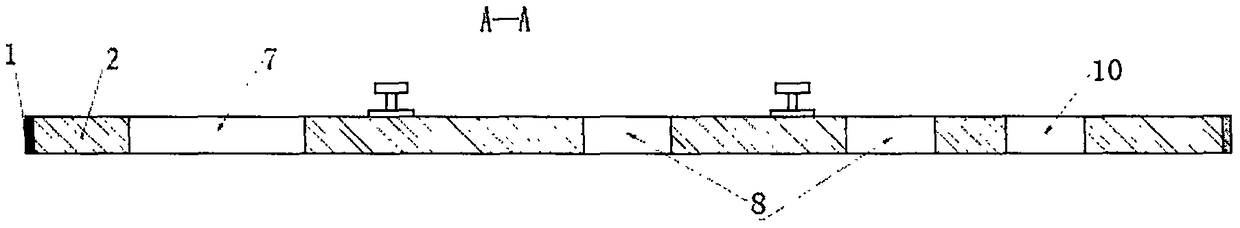

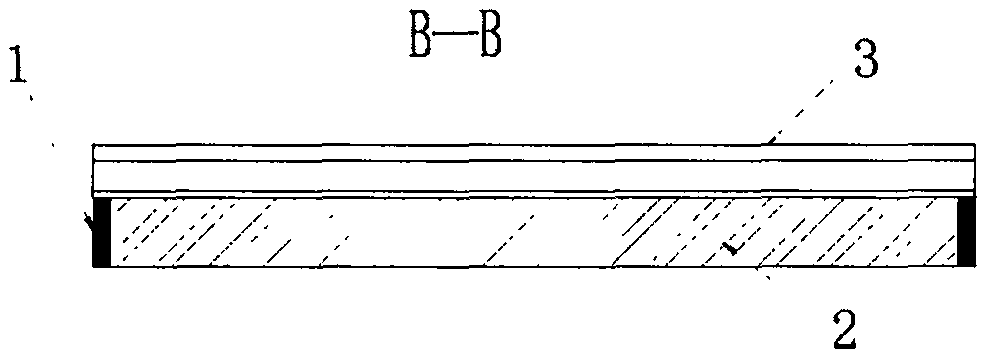

[0026] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0027] like Figure 1 to Figure 4 Shown: a composite frame structure covering for a long-life tundish, including a composite frame structure 1, a refractory material 2 and a triangular anchor 6, and the composite frame structure 1 includes an outer beam 3, a rectangular frame 4 and a rib 5 , the rectangular frame 4 is welded and connected by the transverse side plate and the longitudinal side plate, the rib plate 5 is arranged inside the rectangular frame, the rib plate is connected by the transverse rib plate and the longitudinal rib plate, and the triangular anchor 6 Evenly fixed on the rectangular frame 4 and the rib plate 5, the composite frame structure 1 and the refractory material 2 are integrally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com