Polymer composite film, preparation method thereof and lithium ion battery comprising same

A polymer and composite film technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of reduced bonding performance, poor high temperature thermal stability of composite films, and poor viscosity, etc., to increase mechanical performance, stability improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

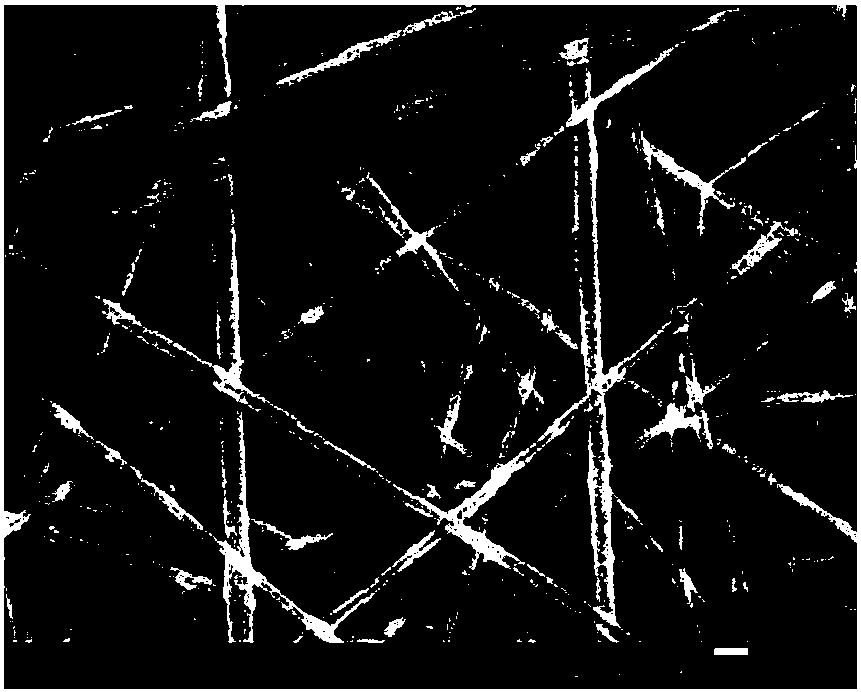

Image

Examples

preparation example Construction

[0034] The preparation method of the ceramic diaphragm provided by the present invention realizes optimal dispersion of ceramic particles by controlling the amount of each component in the ceramic layer slurry, the number average molecular weight of the dispersant, and the rotational speed of the ceramic layer slurry, thereby controlling the packing density between the ceramic particles To control the surface density of the ceramic layer at a unit thickness (1μm) to 1.8mg / cm 2 2 In this way, the high temperature heat shrinkability of the ceramic diaphragm can be improved on the basis of basically not reducing the gas permeability, so that the heat resistance temperature can reach above 160°C, that is, the thermal stability can be improved without increasing the thickness of the ceramic layer, so that Does not affect the energy density of the battery.

[0035] According to the polymer composite membrane of the present invention, preferably, in the ceramic layer, relative to 100...

Embodiment 1

[0087] Embodiment 1 (preparation of two-layer polymer composite film of PE base film-heat-resistant layer)

[0088] This example is used to illustrate the polymer composite membrane provided by the present invention and its preparation method.

[0089] (1) Form a heat-resistant layer on the PE base film:

[0090] Polymphenylene isophthalamide (PMIA) (commercially purchased from Yantai Taihe New Materials Co., Ltd., the same below) and lithium chloride (commercially purchased from Aladdin Reagent Company) with a weight of 0.4% by weight of PMIA weight , analytically pure, the same below) was added to N,N-dimethylacetamide (DMAc) (commercially purchased from Aladdin Reagent Company, the same below), and magnetically stirred in a water bath at 70°C to fully dissolve it to form a polymer A spinning solution having a concentration of 15% by weight of the substance (the aforementioned PMIA).

[0091] One side surface of the PE base film of 11 μm (purchased from Japan SK Company, t...

Embodiment 2

[0097] Embodiment 2 (preparation of three-layer polymer composite film of heat-resistant layer-PE base film-heat-resistant layer)

[0098] This example is used to illustrate the polymer composite membrane provided by the present invention and its preparation method.

[0099] (1) Forming a heat-resistant layer: adopt the method in Example 1 to form the first heat-resistant layer (thickness is 1.5 μ m, porosity 79%) on one side of PE base film earlier, then on the other side of PE base film A second heat-resistant layer (thickness 1.5 μm, porosity 79%) was formed, and polymer composite membrane F2 was obtained after immersion and drying treatment. Detected by an energy spectrometer (EDS), 99.5% by weight of the heat-resistant layer is PMIA, and the rest are solubilizing residues.

[0100] After testing, the transverse tensile strength and longitudinal tensile strength of the polymer composite membrane F2 are 146MPa and 148MPa respectively, the needle punching strength is 0.53kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com