Weaving and post-processing method of three-layer non-filling cotton clothing fabric

A technology for fabrics and cotton clothing, which is applied in the field of preparation of three-layer non-filling cotton clothing fabrics. It can solve the problems of poor variability, non-recoverability, and easy faulting of the cotton core, and achieve bulkiness that is easy to maintain, difficult to flow and shrink, and can be good retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

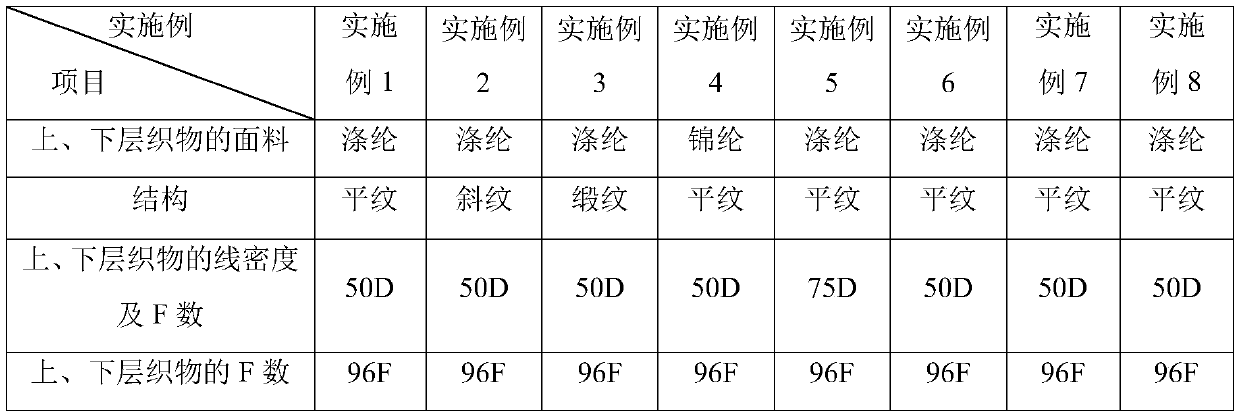

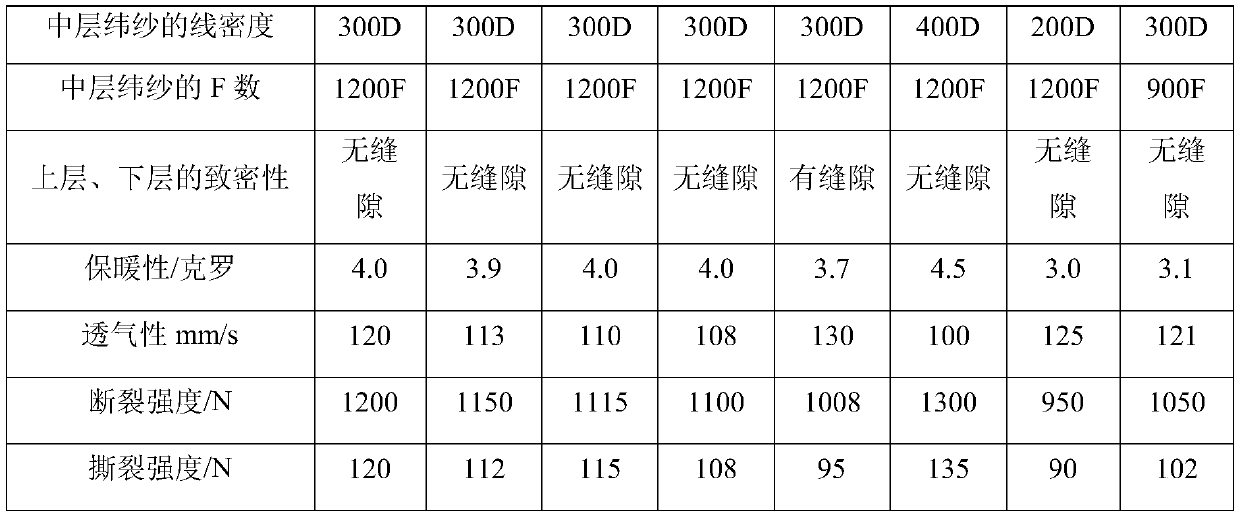

[0056] Embodiment 1: the preparation process of fabric is as follows:

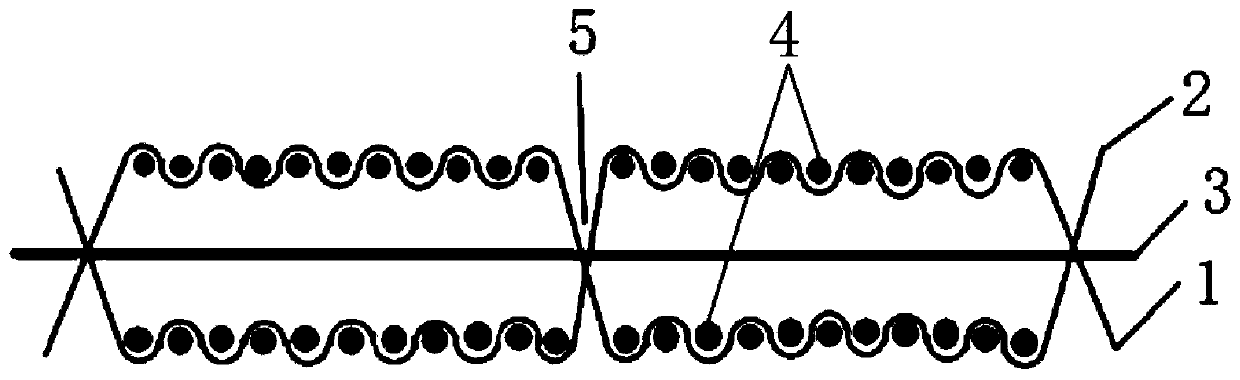

[0057] (1) Raw material preparation: weft yarn 1, weft yarn 2 and warp yarn 4 are all made of polyester 50D yarn, the number of F is 96, the middle weft yarn 3 is made of polyester open fiber yarn, the linear density is 300D, and the single F is superfine denier. F number is 1200;

[0058] (2) warping: warping in batches;

[0059] (3) Sizing: the sizing method is single dipping and single pressing, and the size is made of acrylate;

[0060] (4) Drafting and reeding: the drafting method is the fly-through method, and the reeding adopts 4 entries, that is, 2 upper-layer warp yarns plus 2 lower-layer warp yarns;

[0061] (5) Uniaxial weaving: the beating sequence of weft yarn 1, weft yarn 2 and weft yarn 3 is: 2 weft yarns 1 → 2 weft yarns 2 → 1 weft yarn 3; The weight is 160Kg, and the height of the heald frame is 128mm;

[0062] B. Post-processing:

[0063] (1) Cold pile: The temperature of the cold pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com