Warm-keeping and heat-preservation textile fabric and preparation method thereof

A technology for textile fabrics and inner temperature, applied in the field of textiles, can solve the problems of compression and dispersion of the filling layer, poor thermal insulation performance of thermal insulation fabrics, and low static air content in the filling layer, etc., and achieves the effect of reduced possibility and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

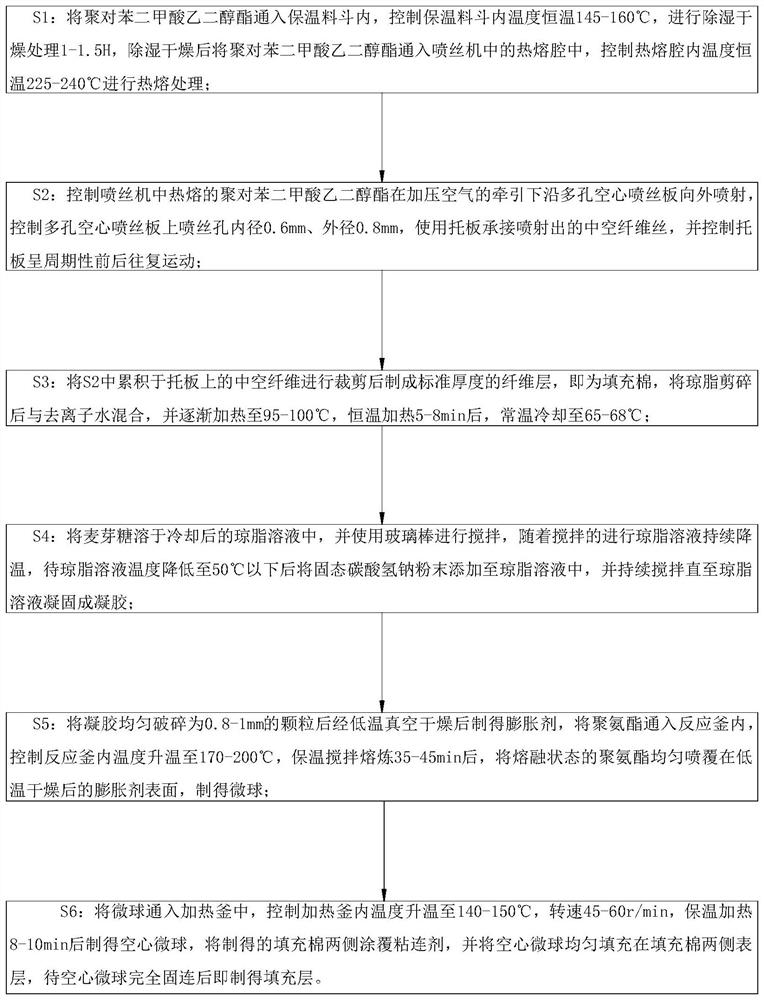

[0047] As an embodiment of the present invention, the preparation method of the filling layer comprises the following steps:

[0048] S1: Put polyethylene terephthalate into the insulation hopper, control the temperature in the insulation hopper to a constant temperature of 145-160°C, perform dehumidification and drying treatment for 1-1.5H, and dehumidify and dry the polyethylene terephthalate The ester is passed into the hot-melt chamber of the spinneret, and the temperature in the hot-melt chamber is controlled to a constant temperature of 225-240°C for hot-melt treatment;

[0049] S2: Control the hot-melt polyethylene terephthalate in the spinneret to spray outward along the porous hollow spinneret under the traction of pressurized air, and control the inner diameter of the spinneret hole on the porous hollow spinneret to be 0.6mm, The outer diameter is 0.8mm, and the supporting plate is used to accept the ejected hollow fiber filaments, and the supporting plate is control...

Embodiment 1

[0071] The thermal insulation textile fabric includes a surface layer, a filling layer and a contact layer; the surface layer, filling layer and contact layer are arranged in sequence from outside to inside;

[0072] The surface layer is made of chemical fiber material with hydrophobic properties; the thickness of the surface layer is 3mm;

[0073] The contact layer is a fiber layer with soft and silky properties; the thickness of the contact layer is 3mm;

[0074] The filling layer is a fiber layer with thermal insulation properties; the filling layer is a fluffy body made of chemical fiber material hot-melt; the filling layer is a three-dimensional network-like spatial structure fixed to each other; ;

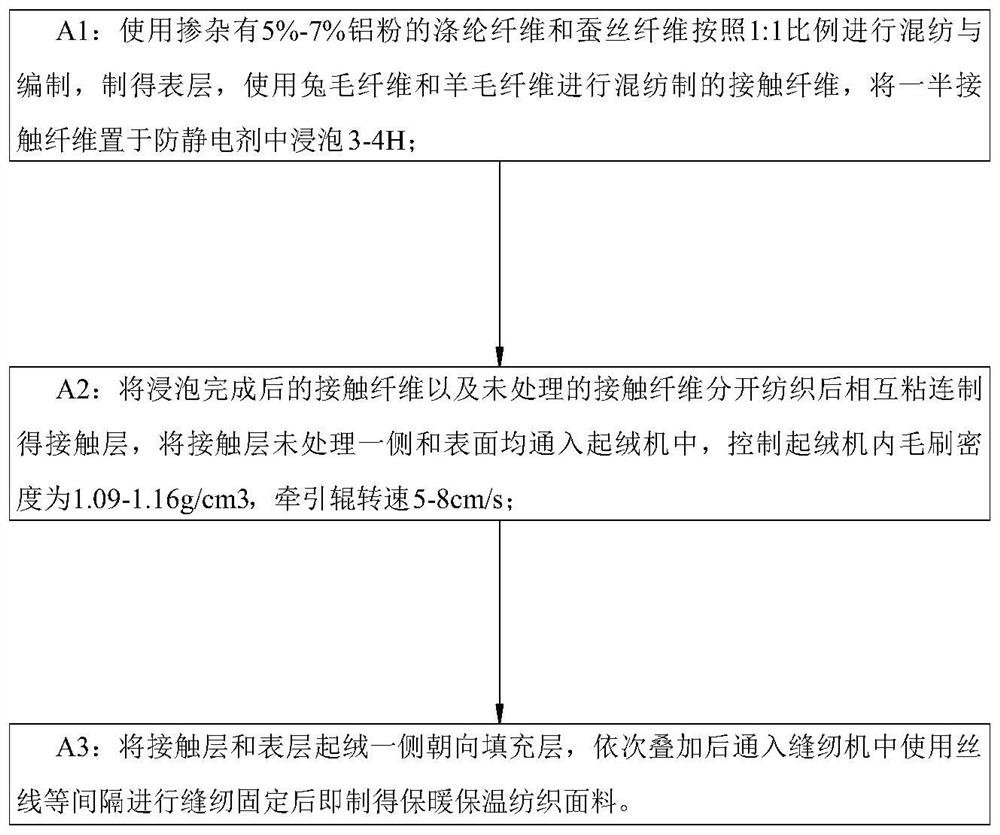

[0075] Use polyester fiber and silk fiber to blend and weave according to the ratio of 1:1 to make the surface layer, use rabbit hair fiber and wool fiber to blend the contact fiber, use the contact fiber to weave to make the contact layer, use polyethylene terephthalic acid...

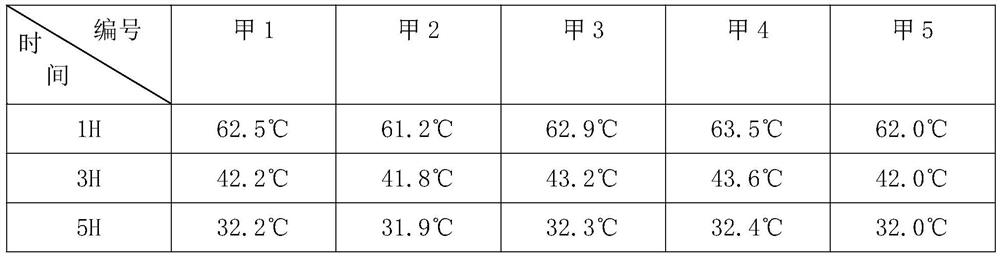

Embodiment 2

[0083] The thermal insulation textile fabric includes a surface layer, a filling layer and a contact layer; the surface layer, filling layer and contact layer are arranged in sequence from outside to inside;

[0084] The surface layer is made of chemical fiber material with hydrophobic properties; the thickness of the surface layer is 3mm;

[0085] The contact layer is a fiber layer with soft and silky properties; the thickness of the contact layer is 3mm;

[0086] The filling layer is a fiber layer with thermal insulation properties; the thickness of the filling layer is 14mm; the filling layer is composed of filling cotton and filling balls; the filling ball has a hollow structure and is filled with carbon dioxide gas; the filling ball Evenly filled in the surface layer on both sides of the filling cotton; the filling cotton is a fluffy body made of chemical fiber material hot-melt; the filling cotton is a three-dimensional network space structure fixed to each other; the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com